You need to produce precise foam inserts for packaging and components, but you're focused on the wrong things. You're comparing laser wattage, cutting speeds, and machine prices, thinking a more powerful laser is the answer. This approach leaves you vulnerable to a catastrophic mistake: choosing the wrong foam. This could lead to toxic fumes, damaged equipment, and a failed investment, all because the most critical factor was completely overlooked.

The single most dangerous mistake when laser cutting foam is ignoring its chemical composition and attempting to cut a PVC-based foam. Unlike safe materials like polyethylene, which vaporize cleanly, PVC foam releases highly corrosive hydrochloric acid when heated by a laser. This toxic gas poses a severe health risk to operators and will actively destroy the laser's sensitive optics, metal components, and motion control system, leading to catastrophic machine failure.

I’ll never forget a call I got from a new business owner. He had just bought a laser from another supplier and was ecstatic to start making inserts for his products. Two days later, he called me in a panic. His machine was making grinding noises, and a strange, acrid smell filled his workshop. My first question wasn't about his laser's settings; it was, "What is the exact type of foam you are cutting?" After a moment of silence, he admitted he didn't know; he just bought some cheap foam from a local supplier. It turned out to be a PVC foam. The hydrochloric acid had already started corroding the guide rails. His brand-new machine was on its way to being destroyed because no one told him that the material matters more than the machine.

Why Aren't All Foams Created Equal for Lasers?

You see a sheet of foam and think of it as a simple, inert material. Your job is to source it at the best price. You assume that if a laser can cut one type of foam, it can cut them all. This assumption puts you at risk of sourcing a material that is not only incompatible but actively destructive to your equipment and hazardous to your staff.

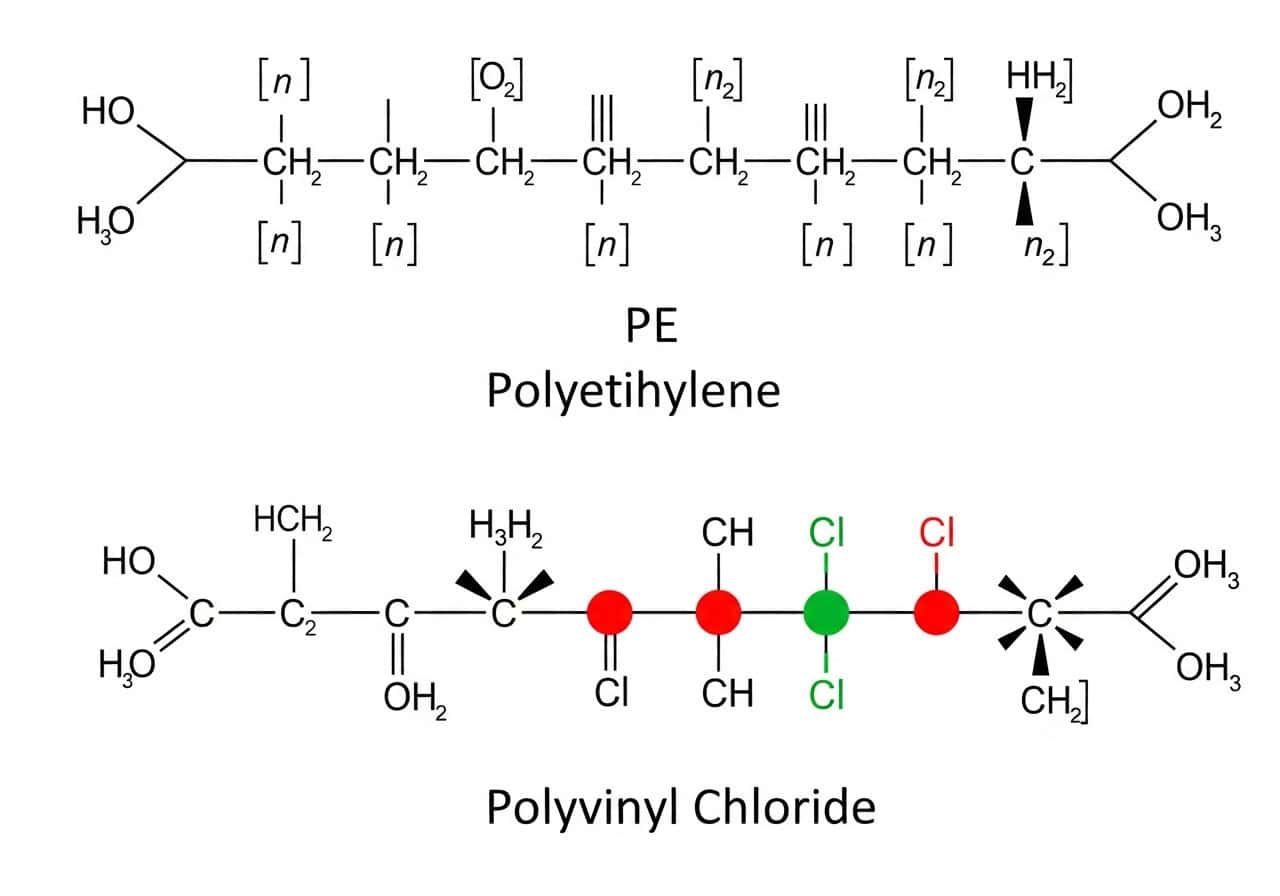

Foams are not equal because they are made from fundamentally different polymers, and each polymer has a unique thermal reaction. A laser doesn't "cut" foam in a mechanical sense; it vaporizes it with intense heat. Laser-safe foams like Polyethylene (PE) or EVA are composed of carbon and hydrogen, which vaporize cleanly. In contrast, dangerous foams like Polyvinyl Chloride (PVC) contain chlorine, which turns into corrosive acid when heated.

For a purchasing manager like John, the Material Safety Data Sheet (MSDS) is a more important document than the laser's spec sheet. Understanding the basic polymer families is non-negotiable.

1. Laser-Safe Foams: Clean Vaporization

These materials are ideal for laser processing because their chemical structure leads to a clean thermal decomposition.

- Polyethylene (PE): This is the foam used for Kaizen inserts and high-end packaging. It vaporizes cleanly with minimal residue, leaving a beautifully sealed and slightly raised edge.

- Polypropylene (PP): Similar to PE, it's a stable polymer that cuts very well.

- Polyester (PES): Often used in filters and acoustic panels, it cuts cleanly and without hazardous fumes.

- EVA (Ethylene-vinyl acetate): The soft, rubbery foam used in floor mats and craft projects. It also cuts very well with a laser.

2. Laser-Unsafe Foams: The Chlorine Problem

The presence of chlorine is the universal red flag for laser processing.

- Polyvinyl Chloride (PVC): The primary offender. The "C" stands for Chloride. When the laser's heat breaks the polymer chain, the chlorine atom is released and combines with hydrogen from the air to form hydrochloric acid (HCl) vapor. This acid will rust and corrode any metal it touches and can permanently cloud the laser's optics.

3. How to Identify Your Foam

Never guess. Always verify a foam's composition before it enters your facility.

- Check the MSDS: The safest method. The data sheet will explicitly state the material's composition.

- Ask the Supplier: Demand confirmation in writing that the material is PVC-free.

- Look for Clues: PVC-based foams often have a distinct, almost sweet chemical smell and can feel slightly denser or less "spongy" than PE foams. When in doubt, do not cut.

What Is a Laser Actually Doing to the Foam?

You're used to thinking about cutting in mechanical terms—blades, routers, waterjets. You see a laser as just a very precise, hot knife. This mental model is incomplete and leads to poor decision-making. It doesn't explain why the edges look sealed or why some foams produce so much smoke, making it hard to troubleshoot issues effectively.

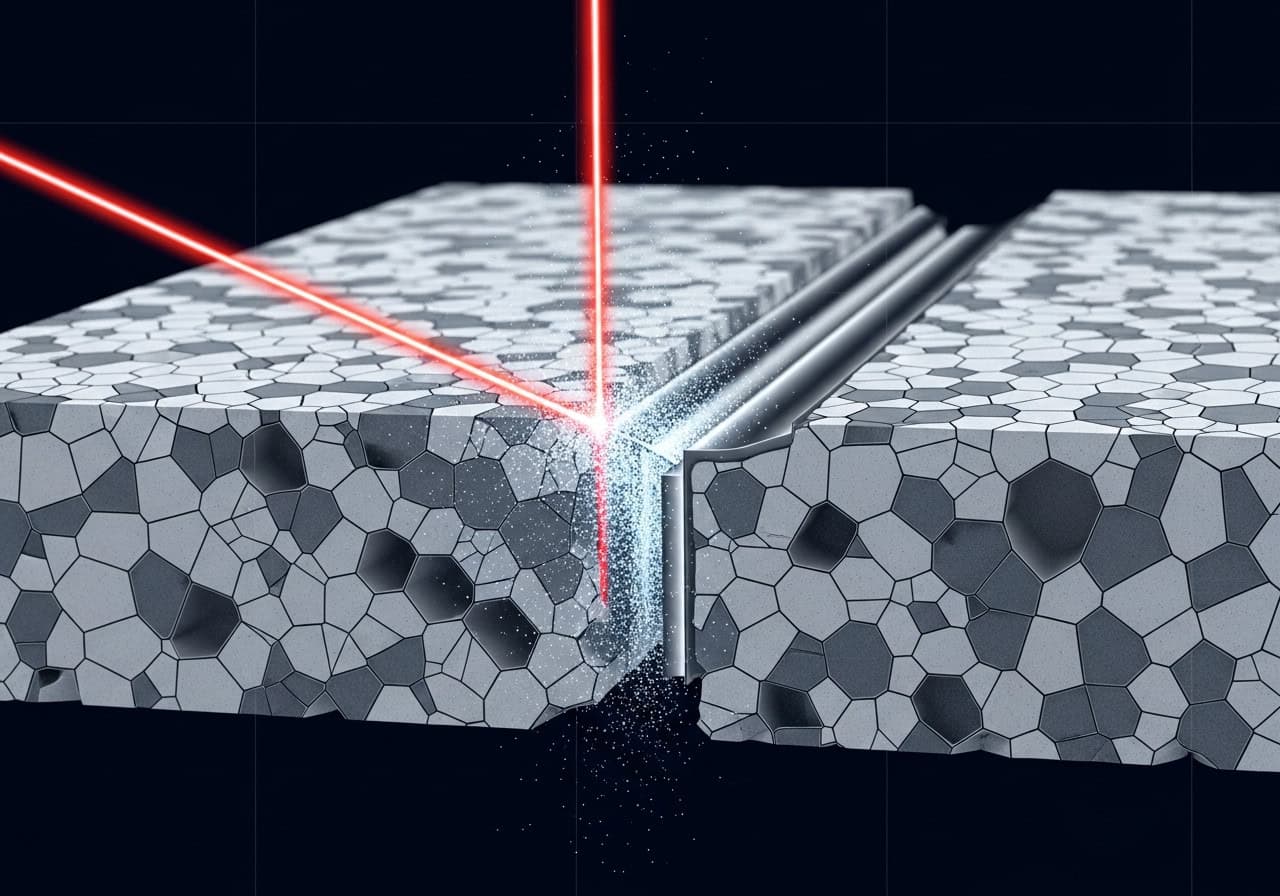

A laser cuts foam through a process called sublimation or vaporization. The intense, focused energy of the laser beam instantly heats the foam's polymer structure past its melting point, directly turning the solid material into a gas. This non-contact process is what allows for such fine detail. The residual heat from this reaction also gently melts the surrounding cell walls, creating the signature smooth, sealed edge that prevents crumbling.

Understanding the physics allows you to control the outcome. The quality of a laser-cut foam product is a direct result of managing this thermal reaction.

1. Absorption and Vaporization

A CO₂ laser's infrared wavelength is highly absorbed by the polymers in foam. This energy transfer is incredibly efficient and localized. The material in the laser's direct path doesn't have time to melt and flow away; it's instantly converted into vapor (smoke). This is why effective smoke extraction is non-negotiable for foam cutting.

2. The Heat-Affected Zone (HAZ)

While the vaporization is happening, a tiny amount of heat conducts into the material right next to the cut line. This is the Heat-Affected Zone. In foam, this HAZ is beneficial. It melts the walls of the foam cells at the edge of the cut. When this melted material cools, it forms a solid, smooth, and slightly densified skin.

3. The Sealed Edge Advantage

This thermally sealed edge is the primary quality differentiator between laser cutting and other methods.

- Mechanical Cutting (Blades/Routers): Tears and rips the foam cells, leaving a rough, open-celled edge that can crumble and shed particles.

- Laser Cutting: Creates a smooth, closed-cell edge that is clean, durable, and particle-free. This is critically important for sensitive applications like electronics or medical device packaging.

| Cutting Method | Edge Quality | Particle Shedding | Intricacy Level |

|---|---|---|---|

| Die-Cutting | Crushed, torn cells | High | Low |

| Router/Blade | Rough, open cells | High | Medium |

| Waterjet | Clean but wet, open cells | Medium | High |

| Laser Cutting | Smooth, sealed, closed cells | None | Very High |

How Do You Choose the Right Laser for Foam?

Now that you know the material is the most important factor, you still need to choose a machine. You see a huge range of options, from small desktop lasers to large industrial systems, and you're worried about overspending on a machine you don't need or underspending on one that can't handle your production volume.

Choosing the right laser for foam cutting depends on three main factors after material safety is confirmed: the thickness of the foam, the size of your parts, and your required production speed. A lower-power CO₂ laser (40-60W) is often sufficient for thin foams, while thicker materials (over 1 inch) benefit from higher power (80-120W) for a clean, straight cut. The machine's bed size must accommodate your largest parts.

Once you've ensured you're only cutting safe foams like PE or EVA, you can focus on the hardware.

1. Power and Foam Thickness

There's a direct relationship between laser power and the quality of the cut on thick foam.

- Thin Foam (< 1 inch): A 40W to 80W laser is perfect. More power doesn't necessarily improve the cut and can be overkill.

- Thick Foam (> 1 inch): A 100W to 150W laser is recommended. Higher power allows the beam to remain focused through the material's depth, preventing a "V" shape in the cut and ensuring straight, perpendicular edges.

2. Bed Size and Passthrough

The machine's work area must be larger than the parts you intend to cut. If you are working with standard 4'x8' foam sheets, you will need a machine with a large bed to process the whole sheet at once. Some machines also offer a "passthrough" slot, which allows you to slide an oversized sheet through the machine, processing it in sections.

3. Critical Accessories: Air Assist and Fume Extraction

These are not optional for foam cutting.

- Air Assist: A strong jet of compressed air directed at the cut point is essential. It blows away vaporized material, prevents flare-ups, and ensures a clean cut.

- Fume Extraction: Foam produces a large volume of smoke. An appropriately sized fume extraction system is mandatory for operator safety and to keep the laser's optics clean.

What Are the Typical Applications for Laser-Cut Foam?

You might only be thinking about one specific use for foam, like basic packaging. This limited view prevents you from seeing how a single laser machine can be a versatile asset, opening up new, high-margin product opportunities for your company across different departments or even industries.

The most common application for laser-cut foam is creating custom, high-precision inserts for protective cases, known as tool foam organizers or shadow boards. Other key applications include custom packaging for sensitive electronics, architectural models, signage and lettering, prop making for film and theater, and creating custom gaskets and seals. The precision and sealed-edge quality make it ideal for any application requiring a perfect fit and a clean, particle-free finish.

A laser's versatility allows it to serve multiple functions within a business.

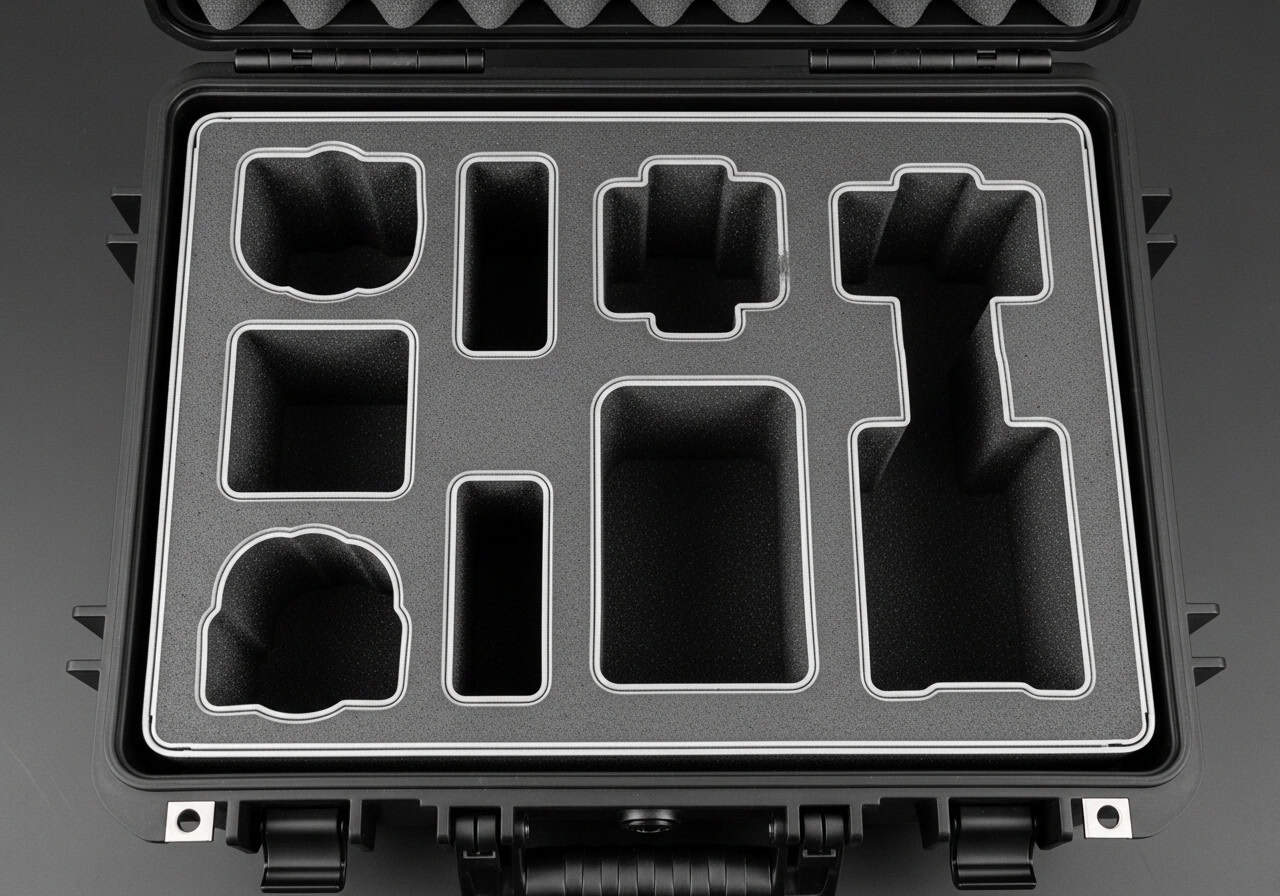

1. Protective Case Inserts

This is the number one application. Companies use lasers to cut multi-layered PE foam (like Kaizen foam) to create perfect nests for tools, camera equipment, medical devices, and sales demonstration kits. The precision ensures a snug fit, and the sealed edge prevents foam particles from contaminating the equipment.

2. Custom Product Packaging

For high-value or fragile products, a custom-cut foam insert provides superior protection and a premium unboxing experience. It communicates a high level of quality and care to the end customer, which is far superior to generic packing peanuts or bubble wrap.

3. Signage and 3D Lettering

Thicker EVA or PE foam can be laser-cut1 to create lightweight, three-dimensional letters and logos for trade show displays, office reception areas, and retail environments. The process is fast, precise, and much more cost-effective2 than traditional sign-making methods for custom jobs.

Conclusion

The conversation about laser cutting foam must always begin with the foam itself. The novice asks about the machine; the expert asks about the material's chemistry. Understanding the critical difference between a safe, clean-cutting polyethylene and a hazardous, machine-destroying PVC is the most important lesson. Once material safety is assured, the laser process offers unparalleled advantages: perfect precision, zero tool wear, and a uniquely clean, sealed edge that mechanical methods cannot replicate. This knowledge transforms the laser from a simple cutting tool into a strategic asset for creating high-quality, high-value products.

FAQs

Q1: What is the most important factor when choosing to laser cut foam?

A: The absolute most important factor is the foam's chemical composition. Before considering any machine specs, you must verify the foam is laser-safe (like PE or EVA) and not a hazardous material like PVC, which will release corrosive acid and damage your machine.

Q2: Which types of foam are safe to cut with a CO₂ laser?

A: The safest and most common foams are Polyethylene (PE), Polypropylene (PP), Polyester (PES), and Ethylene-vinyl acetate (EVA). These polymers vaporize cleanly without producing hazardous byproducts, resulting in a smooth, sealed edge.

Q3: Which type of foam should I absolutely never laser cut?

A: You must never, under any circumstances, attempt to laser cut Polyvinyl Chloride (PVC) foam. It releases highly corrosive hydrochloric acid gas, which is a severe health hazard and will permanently damage the laser's optics and mechanical components.

Q4: How can I tell if a foam contains PVC?

A: The only guaranteed way is to check the Material Safety Data Sheet (MSDS) or get written confirmation from your supplier that the material is PVC-free. Never cut an unknown foam. If you are ever in doubt, do not proceed.

Q5: What does a laser actually do to foam to cut it?

A: A laser doesn't cut mechanically. It uses focused heat to instantly vaporize (turn from solid to gas) the foam material in its path. Residual heat melts the walls of the foam cells right at the edge, creating a clean, smooth, and sealed finish.

Q6: Why is a "sealed edge" on laser-cut foam so important?

A: A sealed edge is smooth, durable, and does not shed particles. This is critical for packaging sensitive electronics, medical devices, or tools where contamination from crumbling foam particles could cause damage or failure.

Q7: Do I need a high-power laser to cut thick foam?

A: For foam over 1 inch thick, a higher-power laser (100W+) is recommended. It ensures the beam can cut straight, perpendicular edges all the way through the material, avoiding a tapered or "V-shaped" cut that can occur with lower-power machines.

Q8: Are fume extraction and air assist necessary for cutting foam?

A: Yes, they are absolutely mandatory, not optional. Foam produces a large volume of smoke (vaporized material) that must be safely extracted. Air assist is crucial for blowing away debris from the cut, preventing flare-ups, and ensuring a clean edge.

Q9: Can I engrave on foam as well as cut it?

A: Yes. By using a lower power setting and a higher speed, the laser will only vaporize the top surface of the foam without cutting through. This is great for creating pockets for tools at specific depths or for adding part numbers and logos.

Q10: What is "Kaizen foam" and why is it popular for laser cutting?

A: Kaizen foam is a brand name for multi-layered Polyethylene (PE) foam. It's popular because it's a laser-safe material, and the layered structure makes it easy to create custom, multi-depth pockets for organizing tools and equipment with a laser cutter.