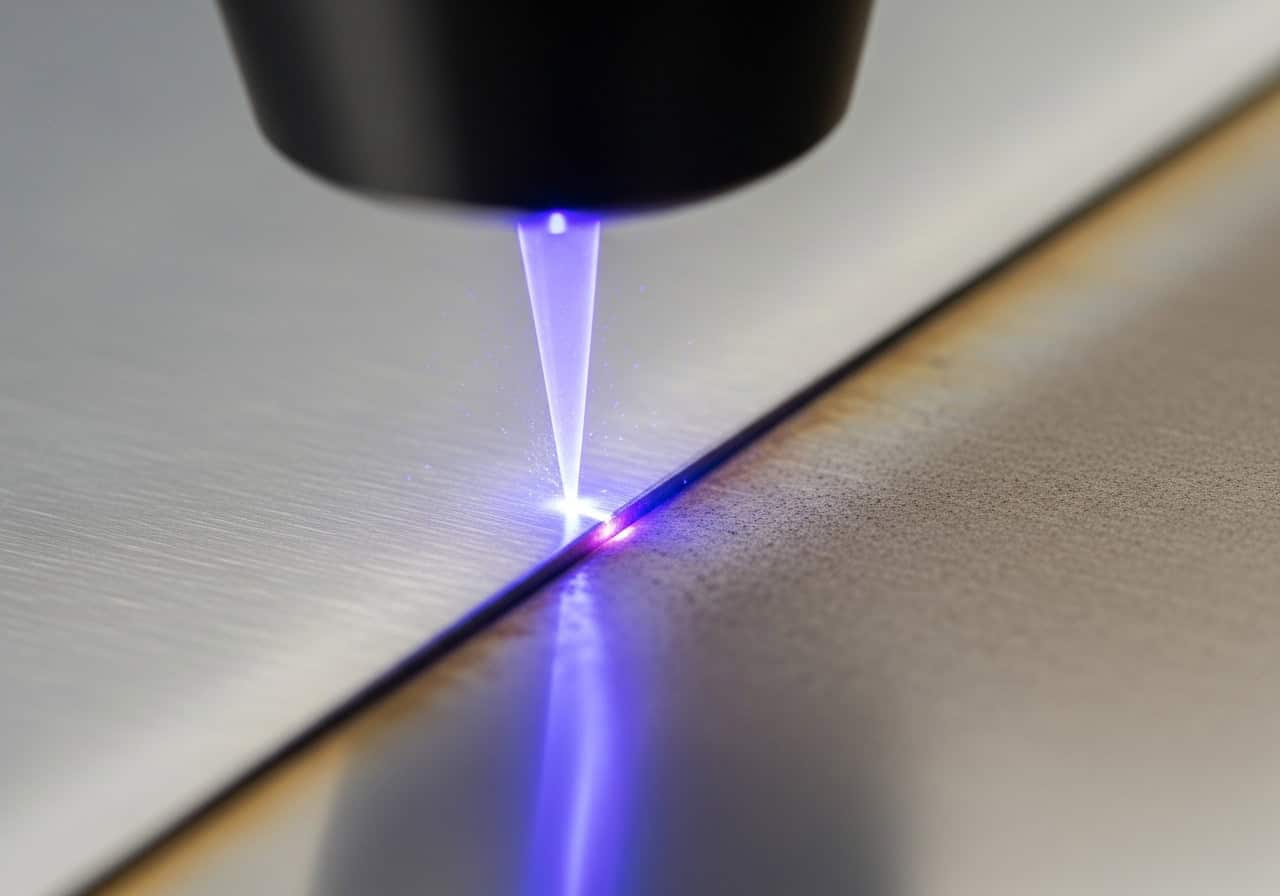

You're looking into laser cleaning, a technology that promises a fast, precise, and chemical-free process. You've seen it work wonders on steel and assume it will be just as straightforward for your aluminum parts. But what if that assumption is wrong? What if the unique physics of aluminum could lead to warped components, hidden micro-fractures, or even a melted surface, turning a promising investment into a costly production problem?

Laser cleaning aluminum is fundamentally different from cleaning steel due to aluminum's high thermal conductivity and high reflectivity. A huge amount of initial laser power is required to overcome the reflective surface. However, that same energy then spreads rapidly through the metal because of its high conductivity. This creates a significant risk of overheating and warping the part, making the process a delicate balancing act of high-stakes thermal management rather than simple surface cleaning.

This is something I explain to clients almost every week. They see a video of a laser vaporizing rust from steel and think, "Great, I'll do that with my aluminum components." But from an operator's perspective, it's a completely different game. With steel, the heat stays where you put it. With aluminum, the moment the laser energy is absorbed, the metal tries to spread that heat everywhere, instantly. I've been working with these machines at Redshift Laser for years, and I can tell you that successfully cleaning aluminum isn't just about pointing and shooting; it's about fighting the metal's own physics to prevent damage. Let's dig into why this is so critical.

Have I Worked with Laser Cleaning Aluminum?

You see the impressive online demos of lasers zapping away contaminants, and you're wondering if that's just marketing hype. Is it truly effective on a tricky metal like aluminum, or is it a solution that only works in perfect lab conditions? You're hesitant to invest in a technology without knowing if it can handle your specific, real-world applications. The risk of buying a machine that fails on your most common materials is high.

Yes, at Redshift Laser, we have extensive hands-on experience laser cleaning aluminum across various industries. Our work ranges from preparing aluminum for welding in automotive to restoring delicate architectural elements. This experience has taught us that success depends entirely on understanding aluminum's unique physical properties. It requires precisely calibrated laser parameters to achieve a perfect clean without causing any thermal damage to the substrate, a lesson we've learned through many challenging projects.

A Challenging Automotive Project

I remember a client who came to us needing to remove a tough oxide layer from thin-walled aluminum automotive parts before welding. They had tried chemical processes, which were slow and hazardous. They assumed laser cleaning would be a simple drop-in replacement. We knew it would be more complicated.

The Initial Problem: Reflectivity

Our initial tests using standard steel settings did almost nothing. The laser beam, bright and powerful, simply reflected off the shiny aluminum surface. The energy wasn't "coupling" with the material. This is aluminum's first defense. To get the process started, we had to significantly increase the fluence (the energy density per pulse) just to break through that reflective barrier.

The Second Problem: Heat Dissipation

Once we had enough power to start the ablation, the second challenge appeared immediately. The heat didn't stay in the small spot we were targeting. Because aluminum is an incredible thermal conductor, the heat started spreading through the entire thin-walled part like wildfire. We saw temperature spikes far from the cleaning area, creating a major risk of warping. This is the core challenge: you need high power to start, but that same high power can quickly become destructive.

Steel vs. Aluminum Cleaning Parameters

| Parameter | Mild Steel | Aluminum (6061) | Reason for Difference |

|---|---|---|---|

| Reflectivity | Moderate | Very High | Needs more initial energy to couple with the surface. |

| Thermal Conductivity | Low | Very High | Heat spreads rapidly, risking damage away from the target area. |

| Required Fluence | Lower | Higher | Must overcome reflectivity to start the ablation process. |

| Risk of Warping | Low (on thick parts) | High (especially on thin parts) | Heat doesn't stay localized; the whole part heats up. |

How Does the Laser Cleaning Process for Aluminum Actually Work?

You understand that laser cleaners remove contaminants, but the actual science can seem like a black box. How does a beam of light just vaporize grime and oxides without melting the metal underneath? Without understanding the "how," you can't properly evaluate different machines or troubleshoot problems. You're left relying on a sales pitch, which might gloss over the details critical for a sensitive material like aluminum.

The laser cleaning process for aluminum works through laser ablation. A high-intensity, pulsed laser beam delivers a massive amount of energy in an incredibly short timeframe (nanoseconds). This energy is absorbed by the contaminant layer (oxide, paint, oil), causing it to heat up and vaporize instantly into a plasma. The key is using a pulse short enough that the heat has no time to conduct into the aluminum substrate below, protecting it from any damage.

The Physics of a Clean Surface

Forget the idea of scrubbing or blasting. Laser cleaning is a much more elegant, thermo-mechanical process. Here’s a simple breakdown of what’s happening in those few nanoseconds.

1. Energy Absorption by the Contaminant

The first step is getting the energy where it needs to go. The laser is tuned so that its energy is readily absorbed by the contaminants (rust, paint, oxides) but reflected by the clean aluminum surface underneath. This creates a natural "stop" point for the process.

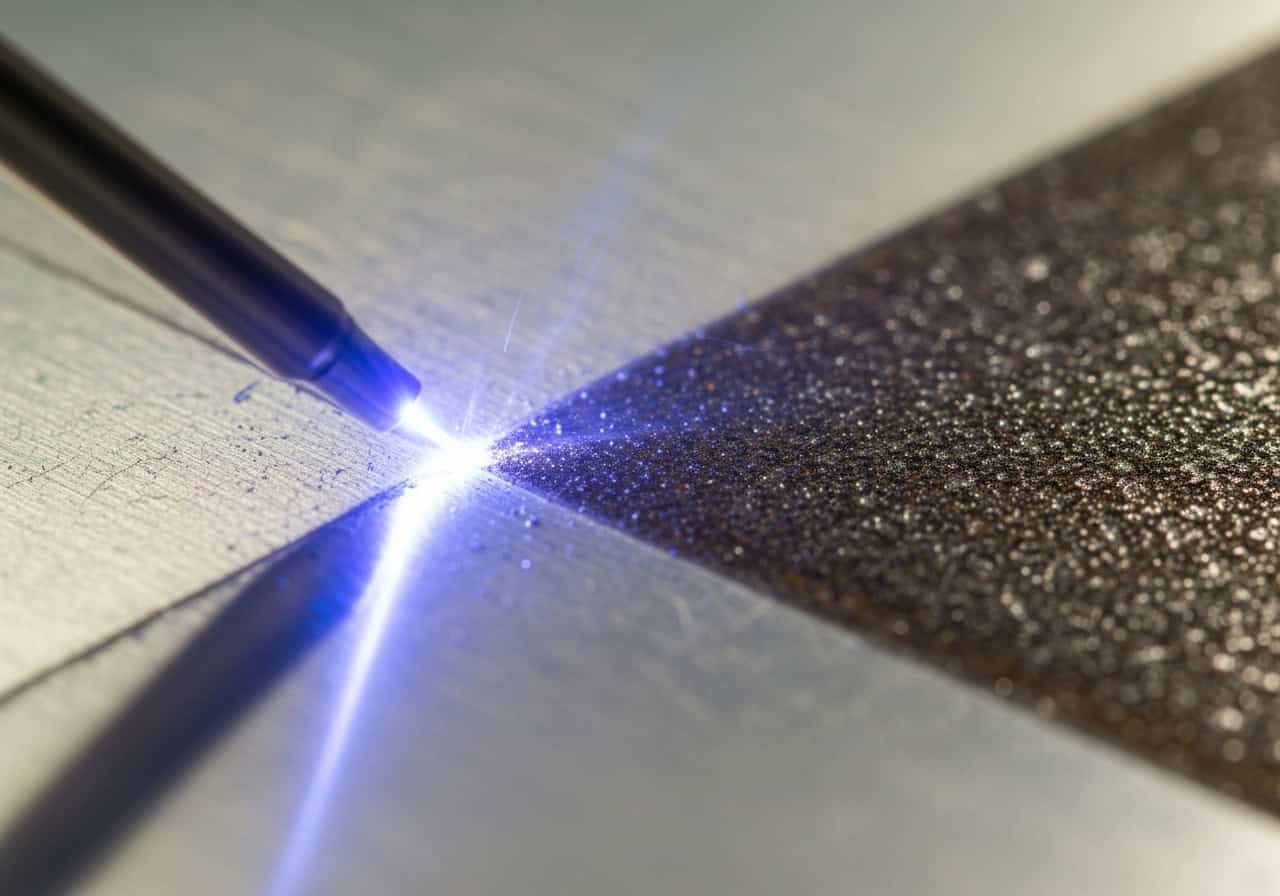

2. Rapid Thermal Expansion and Ablation

When the contaminant layer absorbs the laser pulse, it heats up at a rate of millions of degrees per second. This causes two things to happen simultaneously:

- Vaporization: The material turns directly from a solid into a gas (plasma).

- Shockwave: The rapid expansion creates a micro-shockwave that helps to mechanically eject particles from the surface.

3. Protecting the Aluminum Substrate

This is where the pulse duration is critical. We use pulsed fiber lasers, not continuous wave lasers. A short pulse (e.g., 100 nanoseconds) delivers all its energy and the ablation is over before the heat has a chance to soak into the highly conductive aluminum. If the laser beam were left on continuously, you would simply be welding or cutting, not cleaning.

Laser Cleaning Mechanisms

| Mechanism | Description | Best Suited For | Role in Aluminum Cleaning |

|---|---|---|---|

| Ablation | Instant vaporization of the surface layer. | Oxides, Paint, Thick Coatings | Primary mechanism. The core of the cleaning process. |

| Shockwave | The plasma expansion creates a pressure wave. | Brittle Layers (Rust) | Assists in removing particles efficiently. |

| Selective Absorption | Laser is absorbed by dirt, reflected by metal. | Thin Oil, Fingerprints | Creates a self-limiting effect, protecting the substrate. |

What's the Process for Laser Cleaning an Aluminum Bike Frame?

You're wondering how this technology applies to a real, tangible object. An aluminum bike frame is a perfect example—it has welds, curves, and thin tubes. How do you go from a painted or oxidized frame to a perfectly clean one ready for finishing? You need to understand the practical steps and considerations, not just the theory, to see how it would fit into your own workflow.

The process for laser cleaning an aluminum bike frame involves a systematic approach. First, the frame is securely mounted. Next, the operator performs test spots on an inconspicuous area to dial in the laser parameters (power, frequency, scan speed) to remove the coating without affecting the aluminum. The operator then methodically cleans the entire frame, adjusting for different coating thicknesses and geometries like welds. Finally, the frame is wiped down, leaving a pristine surface.

A Step-by-Step Practical Guide

Let's walk through cleaning a bike frame. This is a great example because it combines thin-walled tubes (high risk of warping) and thick welds (different heat absorption).

Step 1: Secure the Workpiece and Set Safety Zone

First, the frame is placed on a workbench and clamped down so it cannot move. The operator puts on certified laser safety glasses. Safety is always the absolute first step. A fume extractor is positioned over the work area to capture any vaporized particles from the paint and primer.

Step 2: Parameter Testing

This is the most critical step. The operator will find a hidden spot, like the bottom bracket shell, to perform tests. They start with a low power setting and make small test patches, gradually increasing the power until the paint is removed efficiently without leaving any marks on the aluminum. This "dialing in" process is essential to account for the specific paint and aluminum alloy.

Step 3: The Main Cleaning Pass

Using the optimized settings, the operator begins cleaning the main tubes. They use a consistent, steady motion, overlapping each pass slightly to ensure uniform coverage. They will move more quickly over the thin-walled sections to minimize heat input and slow down over thicker areas like the headtube or welds, which can absorb more energy safely.

Step 4: Detail Work and Final Inspection

After the large areas are done, the operator will often switch to a smaller beam spot size to get into tight areas, like the dropouts or cable guides. Once complete, the entire frame is inspected under bright light to look for any missed spots or signs of thermal discoloration. The frame is then wiped with a solvent like isopropyl alcohol to remove any remaining microscopic dust.

Is Laser Cleaning Aluminum Worth It?

You see the benefits—it's precise, clean, and fast. But you also see the challenges—it requires expertise and a significant capital investment. You are likely asking yourself the ultimate business question: Is it actually worth it? You need to weigh the upfront costs and technical demands against the long-term gains in efficiency, quality, and safety to make a sound financial decision for your company.

Yes, for many applications, laser cleaning aluminum is absolutely worth it. While the initial investment is higher than traditional methods, the long-term ROI is compelling. It eliminates the cost of consumables (chemicals, abrasives), reduces labor, creates no secondary waste, and produces a superior, more consistent surface finish. For high-value industries like aerospace, automotive, and electronics, the precision and repeatability of laser cleaning make it an invaluable and highly justifiable technology.

The Business Case: Beyond the Clean Surface

When a purchasing manager like John evaluates this technology, the decision goes far beyond the technical results. It’s about the impact on the entire operation.

1. Reduced Operational Costs

While the machine itself is an investment, it starts paying you back immediately by eliminating recurring costs.

- No Consumables: You stop buying chemicals, solvents, abrasives, and blasting media.

- No Waste Disposal: There is no hazardous chemical waste or contaminated blast media to pay to have hauled away.

- Lower Labor Costs: The process can often be automated and is typically much faster than manual methods.

2. Superior Quality and Consistency

A laser is digitally controlled. Once the parameters are set, it delivers the exact same result every single time. This level of consistency is impossible to achieve with manual sanding or chemical dipping. This means higher quality welds, better paint adhesion, and fewer rejected parts.

3. Enhanced Worker Safety and Environmental Impact

This is a huge factor. You are removing hazardous chemicals and airborne dust particles from your facility. This drastically improves worker safety, lowers your insurance liability, and helps you meet environmental regulations. It's a technology that your safety manager and your compliance officer will love.

Investment vs. Return Comparison

| Method | Upfront Cost | Operational Cost | Quality | Safety/Environment |

|---|---|---|---|---|

| Chemical Stripping1 | Low | High (chemicals, disposal) | Inconsistent | Poor (hazardous) |

| Abrasive Blasting | Medium | High (media, cleanup) | Can damage substrate | Poor (airborne dust) |

| Laser Cleaning2 | High | Very Low (electricity) | Highly Consistent | Excellent |

Conclusion

Laser cleaning aluminum is a powerful, precise technology, but it is not a simple point-and-click solution. Unlike steel, aluminum’s high reflectivity and thermal conductivity demand a deep understanding of the process and careful control of laser parameters. It's a game of thermal management. However, for companies willing to invest in the right equipment and training, the rewards are immense. By eliminating consumables, improving safety, and delivering unmatched quality and consistency, laser cleaning offers a powerful return on investment, transforming a challenging manufacturing step into a streamlined, reliable, and cost-effective competitive advantage.

Frequently Asked Questions

1. Is there a minimum thickness for safely laser cleaning aluminum?

There isn't a single "magic number," as the safe thickness depends on the laser power used and the type of contaminant. However, as a general rule, we become extremely cautious with aluminum under 1mm thick. For very thin sheets, the risk of heat buildup and warping is significant. Success requires using a lower-power laser with a very high scan speed to minimize the time the beam spends on any single spot, preventing heat from soaking in.

2. Can a laser be used to remove anodizing from aluminum?

Absolutely. In fact, this is one of the most effective and precise applications for the technology. The laser ablates the anodized layer cleanly, exposing the raw aluminum underneath without damaging the substrate. We frequently use this process to create electrical grounding points on anodized parts or to selectively strip sections for re-coating or welding.

3. What does the surface finish look like after laser cleaning? Will it be rough?

When calibrated correctly, the laser will not alter the original surface texture of the aluminum. If the metal was smooth before, it will be smooth after cleaning. The goal is to remove only the contaminant layer, leaving the substrate untouched. This is a major advantage over methods like sandblasting or grinding, which inherently roughen the surface by removing parent material.

4. How fast is the process? What kind of cleaning rates can be expected?

The cleaning rate varies dramatically depending on what's being removed. Removing a light oil or oxide layer can be very fast, covering a large area quickly. However, stripping a thick layer of industrial paint or epoxy will be much slower, as more laser energy is required to vaporize the coating. The speed is always a trade-off between the thickness of the contaminant and the power of the laser system.

5. Are the fumes created during the process hazardous?

Yes, the process creates fumes by vaporizing the surface contaminants—be it paint, oil, or oxides. These particles should not be inhaled. That is why a proper fume extraction system is not just recommended; it is an essential and non-negotiable part of any professional laser cleaning setup. A high-quality extractor captures and filters these particles at the source, ensuring a clean and safe work environment for the operator.