You are responsible for producing high-quality filters, but you're battling a hidden problem: edge fraying. Traditional knife or die cutting leaves microscopic frayed ends on your filter cloth. This seems minor, but it leads to particle bypass, compromising the entire filter's integrity. These failures can lead to customer complaints, damage to your brand's reputation, and costly quality control issues that are a nightmare to track down.

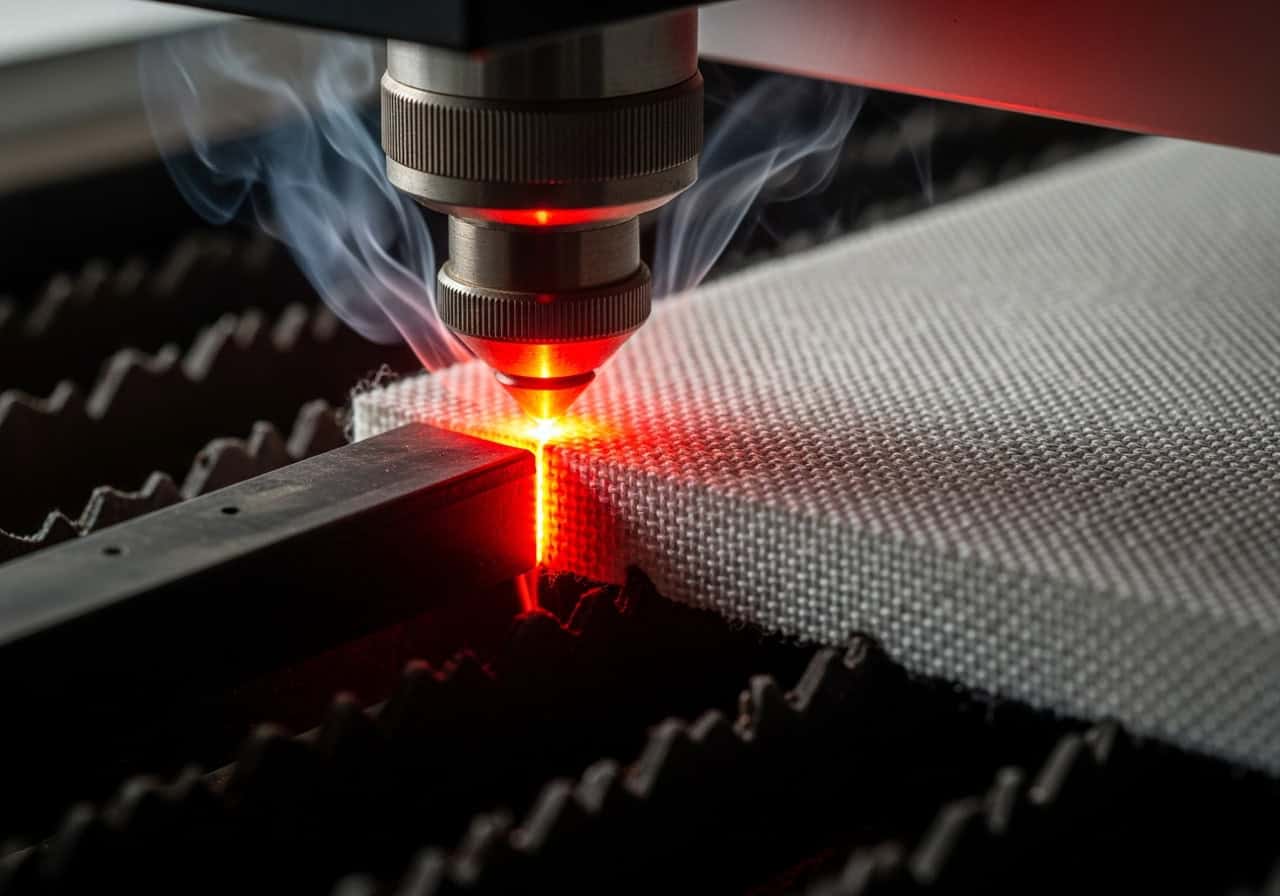

Yes, laser cutting is the best choice for filter cloth because it does more than just cut; it simultaneously seals. The laser's intense heat creates a thermally fused, non-porous bead along the edge of the synthetic fabric. From a fluid dynamics perspective, this solid edge completely eliminates the risk of bypass leakage, where particles could otherwise sneak through frayed, unsealed edges. It's a quality assurance process built directly into the cutting stage.

I remember working with a client who manufactured filters for medical devices. They were struggling with batch-to-batch inconsistency. Their die-cut filters sometimes passed quality control, and other times failed. The problem was microscopic bypass leakage from frayed edges. They were focused on the cut's shape, but not the cut's quality. I showed them how a laser doesn't just cut the cloth but melts and seals the edge into a solid, clean bead. For them, the laser wasn't just a faster tool; it was the solution to their biggest quality problem. Let's dig into why this sealing action is so critical.

What are the Benefits of Laser Cutting Filter Cloth?

You need to produce perfectly shaped filter components, but your current methods are falling short. Die cutting is inflexible and expensive for custom shapes, and the dies wear out over time. Manual or automated knife cutters cause the fabric to fray, tear, or stretch, leading to inconsistent parts that don't fit perfectly and risk filter failure down the line.

The primary benefit of laser cutting filter cloth is the creation of a perfectly sealed, non-fraying edge. This thermal sealing process eliminates particle bypass and ensures filter integrity. Additional benefits include incredible precision for complex shapes, zero tool wear for consistent results over time, and the flexibility to change designs instantly without needing to create expensive new dies. The process is also non-contact, preventing material distortion.

The Thermally Fused Edge: Eliminating Bypass Leakage

This is the most critical benefit, and it's what separates laser cutting from all other methods. When you use a knife or die, you are mechanically severing the fibers. On a microscopic level, this leaves thousands of loose ends, creating a porous, frayed edge. In a filter assembly, fluid can force particles through these unsealed edges instead of through the filter media. This is called bypass leakage. A laser, however, melts the synthetic fibers (like polyester or polypropylene) as it cuts, fusing them into a solid, non-porous bead. This bead acts as a built-in gasket, ensuring the only path for particles is through the filter media itself.

Unmatched Precision and Consistency

A laser beam can be focused to a spot size smaller than a millimeter, allowing for incredibly intricate and precise cuts. This means you can design complex filter geometries that fit perfectly into their housing every single time. Because the process is digitally controlled, the first piece cut is identical to the thousandth, eliminating the inconsistencies that come from die wear or blade dullness.

No Tool Wear and Reduced Maintenance

Mechanical cutters, whether they are blades or dies, wear down. A dull blade stretches the fabric instead of cutting it. A worn die produces parts with slightly different dimensions. This means constant maintenance, sharpening, and eventual replacement, all of which add to production costs and downtime. A laser has no physical contact with the material, so there is no tool to wear out. The cutting quality remains perfectly consistent throughout the machine's life.

Design Flexibility without Tooling Costs

What if you need to test a new filter design or produce a small batch for a custom application? With die cutting, this would require manufacturing a new, expensive die with a long lead time. With a laser cutter, you simply change the digital design file. You can go from one shape to a completely different one in seconds, giving you unparalleled flexibility for prototyping and on-demand production.

How Do Laser Cutters Compare to Other Tools for Filter Cloth?

You're evaluating different cutting technologies and need to make a solid business case. How does a laser stack up against the traditional die cutters or CNC knife systems you're familiar with? Without a clear, side-by-side comparison, it's hard to justify the investment and explain to your team why a laser isn't just another way to cut, but a fundamentally better process.

Compared to other tools, laser cutters offer a unique combination of precision cutting and simultaneous edge sealing. While die cutters are fast for high-volume identical parts, they cause fraying and require expensive tooling. CNC knife cutters are flexible but also fray edges and suffer from blade wear. The laser's non-contact, thermal process eliminates both fraying and tool wear, making it the superior choice for high-integrity filter manufacturing.

A Direct Tool-to-Tool Breakdown

As a purchasing manager, you need to weigh the pros and cons of each technology based on factors like quality, speed, and cost. I've worked with clients who have used all three methods, and the differences are stark.

Die Cutting

This is the classic method for high-volume production. A sharp, custom-shaped die (like a cookie cutter) is pressed through the material.

- Pros: Very fast for mass production of a single shape.

- Cons: Edges are mechanically cut and will fray. Dies are extremely expensive to create and cannot be changed. Wear and tear on the die leads to declining quality over time.

CNC Knife Cutting

This method uses a computer-controlled blade (drag knife or oscillating knife) to cut the shape.

- Pros: Flexible; you can change the design digitally. Faster than manual cutting.

- Cons: Still a mechanical cut, so edges fray. The blade can drag or bunch up delicate fabrics, causing distortion. Blades wear out and must be replaced frequently to maintain cut quality.

Laser Cutting

This method uses a focused beam of light to vaporize the material.

- Pros: Creates a perfectly sealed, non-fraying edge. Extremely precise and repeatable. No tool wear or material distortion. Instantly flexible for any design.

- Cons: The initial machine investment can be higher than a simple knife cutter. Cutting speed may be slower than die cutting for very simple, high-volume shapes.

Technology Comparison Table

| Feature | Laser Cutting | Die Cutting | CNC Knife Cutting |

|---|---|---|---|

| Edge Quality | Excellent (Sealed) | Poor (Frayed) | Poor (Frayed) |

| Precision | Very High | High (when new) | High |

| Design Flexibility | Very High | None | Very High |

| Tool Wear | None | High | Medium |

| Risk of Material Distortion | None (Non-contact) | Low | High (from dragging) |

| Ideal Use Case | High-integrity filters, custom shapes | High-volume single-shape production | Prototyping, low-volume flexible cutting |

How Does a Laser Actually Cut Filter Cloth?

You understand the benefits, but how does a beam of light actually cut through fabric? It might seem like magic, or you might worry it's just a controlled burn that could damage the material. Without understanding the simple physics behind the process, it's hard to feel confident in the technology and explain its reliability to stakeholders.

A laser cuts filter cloth through a process called photothermal ablation. The laser machine's CO2 laser emits a focused beam of infrared light. When this intense energy hits the synthetic filter cloth, the material's fibers instantly absorb it. This rapid absorption heats the fibers past their melting point and vaporizes them in a fraction of a second. This process is so fast and localized that it simultaneously cuts and seals the edge without burning the surrounding material.

The Step-by-Step Process

Seeing the machine in action can look complex, but the process itself is straightforward. From a technical standpoint, here’s what’s happening.

1. The Digital Design

Everything starts with a digital file (like a DXF or AI file). This is the blueprint for your filter shape. You load this file into the laser machine's software. The software translates the lines of your drawing into a path for the laser head to follow.

2. The CO2 Laser Beam

Inside the machine, a laser tube is stimulated with electricity to produce a powerful beam of infrared light. This light is invisible to the human eye. A series of mirrors, known as a beam delivery system, guides this light from the tube to the moving laser head.

3. Focusing the Energy

The laser head contains a special lens, typically made of Zinc Selenide (ZnSe). This lens focuses the entire beam of light down to a tiny, incredibly powerful spot. Think of using a magnifying glass to focus sunlight. This concentration of energy is what gives the laser its cutting power.

4. Vaporization and Sealing

As the laser head moves over the filter cloth, the focused beam makes contact with the material. The synthetic polymer fibers absorb the intense infrared energy and are instantly vaporized—they turn from a solid straight to a gas. This is not burning; it is a much cleaner and more precise process. The heat from this vaporization simultaneously melts the fibers at the very edge of the cut, which then cool and re-solidify into the clean, non-porous bead we value so much. A constant jet of compressed air (air assist) blows the vaporized material away, ensuring a clean cut.

What is the Best Laser Machine for Cutting Filter Cloth?

You're ready to explore purchasing a laser cutter, but the market is full of options with different sizes, powers, and features. How do you choose the right one for industrial filter production? Picking a machine that is underpowered, has an unstable bed, or lacks essential features could lead to poor results and a failed investment, setting your production back instead of moving it forward.

The best laser machine for filter cloth is a CO2 laser cutter with a power of 80W to 130W. Crucially, it must have a large, stable conveyor or pass-through bed to handle material from a roll, a high-quality motion system for precision at high speeds, and an effective exhaust system to manage fumes. The conveyor system is key, as it automates the feeding process, allowing for continuous, efficient cutting directly from the roll, maximizing productivity.

Key Features for Industrial Production

For a serious application like filter manufacturing, you can't just buy any hobby laser. As an expert like John would know, the machine's features must match the demands of the job. Here are the features I always recommend to my clients in the filtration industry.

1. CO2 Laser Source (80W-130W)

Synthetic fabrics are highly reactive to the wavelength of CO2 lasers, making them the perfect choice. A power range of 80W to 130W provides a great balance. It's powerful enough to cut quickly through various filter materials but still controllable enough to create a perfect seal without overheating the surrounding area.

2. Conveyor Worktable and Auto-Feeder

This is the most important feature for industrial efficiency. A flatbed machine requires you to manually place each sheet of material. A conveyor worktable, combined with an auto-feeder, automatically pulls the filter cloth from a large roll, cuts the parts, and then advances the material for the next batch. This enables continuous, "lights-out" operation, dramatically increasing throughput.

3. Large Format Bed

Filters can come in all shapes and sizes, and you often want to nest many small parts onto a single large sheet to minimize material waste. A large format bed (e.g., 1600mm x 1000mm or larger) gives you the space to optimize your nesting and cut large parts without repositioning.

4. High-Quality Motion System

To cut intricate shapes accurately at high speed, the machine needs a robust gantry system1 with high-quality stepper or servo motors2. This ensures the laser head moves smoothly and precisely, without any wobble or backlash, which is critical for maintaining tight tolerances on every part you produce.

Conclusion

When it comes to cutting filter cloth, laser cutting is not just a better choice; it's the best technology for ensuring product integrity. While traditional methods like die or knife cutting will always be plagued by edge fraying, the laser's ability to create a perfectly sealed, non-porous bead is a game-changer. This simple feature eliminates the critical risk of bypass leakage, transforming the cutter from a simple production tool into a vital instrument for quality assurance. For any serious manufacturer, investing in a laser system with features like a conveyor bed is a direct investment in quality, efficiency, and reliability.

FAQ

Q1: What types of filter cloth can be laser cut?

A: Laser cutting works best on synthetic filter cloths. Materials like Polyester (PET), Polypropylene (PP), Nylon, and other thermoplastics are ideal because the laser melts their fibers to create that perfect sealed edge. It is not recommended for natural fibers like cotton or wool, as they tend to char and burn rather than melt and seal cleanly. You should always confirm your material is a synthetic polymer before laser cutting.

Q2: Will the laser's heat damage the filter media or affect its filtration properties?

A: This is a great question, and the answer is no, as long as the settings are correct. The process, called photothermal ablation, is incredibly fast and localized. The laser's energy is focused on a tiny spot, vaporizing the material instantly. The "heat-affected zone" is microscopic and only affects the very edge, creating the seal. The rest of the filter material remains untouched and cool, preserving its structural integrity and filtration rating.

Q3: Is it safe to laser cut filter cloth? What are the fumes like?

A: Yes, it is safe, but only with proper industrial-grade ventilation. Cutting synthetic polymers like polyester or polypropylene releases fumes that must be extracted from the workspace and vented outside. These fumes are not toxic in the same way as PVC, but they are unpleasant and unhealthy to breathe continuously. A powerful exhaust system is not just recommended; it's a mandatory part of a safe and professional setup.

Q4: We produce very high volumes. Is a laser cutter fast enough compared to our die cutter?

A: It depends on the complexity of the part. For a very simple shape, like a circle, a die cutter will be faster in pure cuts-per-minute. However, the laser cutter often wins on overall throughput. Why? Because a system with a conveyor bed automates the material handling, cutting continuously from a roll. When you factor in the elimination of downtime for die changes, maintenance, and the superior quality that prevents rejected parts, the laser cutter is often the more efficient and cost-effective solution for a modern production line.

Q5: Can I just use any CO2 laser, or do I need a special one for filter cloth?

A: While any standard CO2 laser can cut filter cloth, an industrial production environment requires specific features. I'd never recommend a basic flatbed machine for this. You need a machine with an auto-feeding conveyor worktable for handling rolls, a large format bed for nesting parts efficiently, and a power of at least 80W to ensure a clean cut at a productive speed. These features are what separate a hobby machine from a real industrial tool.