Are you struggling with the delicate task of welding thin metal sheets, from 0.1mm to 1.8mm? It feels like walking a tightrope, where one wrong move leads to warping, burn-through, or a weak joint. This constant battle wastes valuable materials, time, and money, putting production schedules at risk. As a purchasing manager, I know this pressure is immense. But what if the solution wasn't more skill, but smarter technology that turns this complex art into a simple, repeatable science?

The core reason welding thin sheets is so difficult lies in heat input management. The goal is to melt just enough material for a strong bond without introducing excess heat that causes distortion. The window for success is incredibly narrow. Our Redshift X1 Handheld Laser Welder, leveraging advanced pulse laser technology, is engineered to master this challenge. It provides the precise control needed to consistently weld materials as thin as 0.1mm, transforming a frustrating task into a reliable process.

I remember a project early in my career with a client, much like John, who needed to fabricate components for high-end electronics. The material was a 0.1mm alloy, and our failure rate was sky-high. Every attempt with traditional methods resulted in a distorted mess. The academic papers I read talked about "heat input" and "weld geometry," but it all felt so theoretical. It wasn't until we brought in our first pulse laser welder that it all clicked. Seeing that machine lay down a perfect, clean weld seam made me realize: the best tools are the ones that embody scientific principles, making them accessible to everyone.

How Do You Master Heat Input to Prevent Warping?

When welding thin sheets, your greatest enemy is uncontrolled heat. Too little, and the weld won't penetrate; too much, and the piece warps instantly. This constant balancing act is stressful and inefficient. You know that excessive heat is the problem, but how do you deliver energy with surgical precision only where it's needed? The answer lies not in working faster, but in changing how the energy itself is delivered.

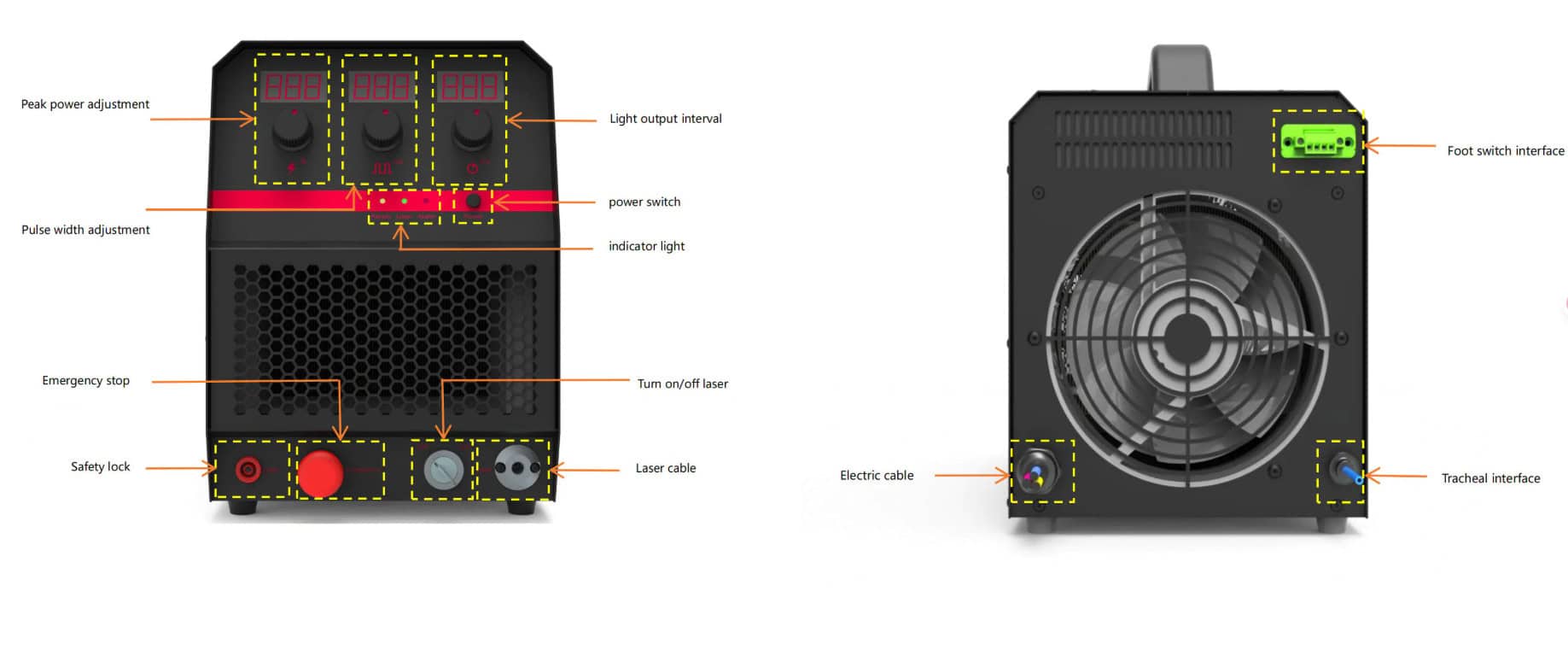

To master heat input, you must control both the pulse energy and the line energy. The research is clear: pulse energy determines the depth of the weld (penetration), while line energy is the total heat accumulated along the seam. The Redshift X1 solves this with two simple knobs. You use the Peak Power Adjustment to set the right pulse energy for penetration, then fine-tune the heat accumulation using the Pulse Width Adjustment, ensuring a strong weld without any distortion.

The Science of Heat Control, Simplified

Technical papers explain that achieving a perfect weld on a 0.1mm sheet is a delicate balance. Our Redshift X1 translates that complex science into an incredibly intuitive process.

1. Pulse Energy: The Key to Penetration

As the research paper highlights, each laser pulse creates a tiny molten pool. The energy of that single pulse must be enough to melt through the material but not so powerful that it creates a hole (weld leak). On the X1, you control this directly with the "Peak power adjustment" knob. This is your primary tool for dialing in the perfect penetration for any thickness between 0.1mm and 1.8mm.

2. Line Energy: The Secret to a Flat Finish

Line energy is the cumulative effect of heat along the weld path. Too much, and the material will warp. You control this by adjusting the pulse duration with the "Pulse width adjustment" knob and the travel speed. A shorter pulse width delivers heat more intensely and for a shorter time, minimizing the Heat Affected Zone (HAZ). This gives you a flat, clean part that requires little to no post-processing.

Comparison of Heat Control Methods

| Feature | Redshift X1 (Pulse Laser) | Traditional TIG Welding |

|---|---|---|

| Heat Input Control | Independent knob control for Pulse & Line Energy | Relies entirely on operator skill (travel speed, amperage) |

| Heat Affected Zone (HAZ) | Extremely small and localized | Wide, leading to material weakness and distortion |

| Warping Risk | Very low | Very high, especially on sheets < 1mm |

| Process Repeatability | High; lock in settings for consistent results | Low; varies between operators and jobs |

This level of simple, direct control empowers any operator to achieve scientifically perfect welds, every single time.

How Do You Achieve a Strong, Continuous Seam?

You've controlled the heat, but now the weld seam itself is inconsistent—strong in some places, weak in others. The surface looks more like a dotted line than a solid connection. How do you ensure the individual weld spots connect perfectly to form a uniform, mechanically sound seam? This is about more than just aesthetics; it's about the structural integrity of your product.

A strong, continuous seam is achieved by controlling the spot overlap rate. The research paper I studied indicates that for a uniform and strong weld, the overlap between consecutive laser pulses should be at least 60%. This ensures each new pulse re-melts a portion of the previous spot, eliminating gaps and creating a continuous molten track. With the Redshift X1, you easily achieve this by balancing your pulse frequency (pulses per second) and travel speed.

From Dotted Lines to Solid Seams

When I first showed John how to adjust for overlap rate, it was a lightbulb moment. He was used to seeing the inconsistent stitch-like appearance of poorly executed welds. He immediately understood its importance.

The Foundation: Why a Zero Gap Matters

Before you even pull the trigger, the academic research confirms a critical first step: the welding gap must be zero. Thin sheets don't have enough molten material to bridge even a tiny gap. The Redshift X1's precision allows you to work with tightly clamped parts, but ensuring your fixtures create a zero-gap fit is step one for a perfect weld.

Achieving the "Golden" 60% Overlap

Once your parts are clamped, creating a continuous seam is a simple two-variable equation on the X1:

- Pulse Frequency (f): How many weld spots are created per second.

- Welding Speed (v): How fast you move the torch.

By slightly increasing the frequency or slowing the speed, you increase the overlap. This covers up any "keyhole" depressions from previous pulses and creates the beautiful, uniform "fish scale" appearance of a perfect weld.

Weld Seam Quality Comparison

| Parameter | Redshift X1 (Optimal Overlap) | Poorly Controlled Welding |

|---|---|---|

| Seam Appearance | Uniform, smooth, continuous | Inconsistent, "dotted" appearance |

| Mechanical Strength | High and consistent | Unpredictable, with weak points |

| Watertightness | Excellent, fully sealed | Prone to leaks and gaps |

| Operator Focus | Focus on smooth travel speed | Constantly adjusting multiple parameters |

With the X1, you're not just melting metal; you are strategically overlapping molten pools to build a structurally superior connection.

How Can a Welding Machine Adapt to Your Real-World Workshop?

Lab conditions are one thing, but your workshop is another. You face fluctuating temperatures, urgent on-site repairs, and limited space. A machine that only works in a perfect environment is a liability. How do you find a tool that is not only precise but also rugged, portable, and flexible enough to meet the unpredictable demands of your business?

The Redshift X1 was designed for exactly these real-world challenges. This is where it moves beyond a lab instrument to become a true industrial workhorse. Weighing just 10kg (22 lbs), it's ultra-portable for any on-site job. More importantly, its advanced air-cooling system and robust design allow it to operate flawlessly in a wide temperature range of -20°C to 45°C (-4°F to 113°F), no bulky water chiller required.

Built for Work, Not for a Laboratory

I'll never forget a call from John on a cold winter morning. A critical piece of equipment for one of his clients failed outdoors, and a thin metal casing had cracked. They couldn't bring the equipment to the shop.

1. The Challenge: Weight and Weather

Their traditional welders were over 100kg and required a water chiller that wouldn't function in the freezing temperatures. They were completely stuck, and production was at a standstill.

2. The Solution: The Redshift X1 to the Rescue

We sent a technician with an X1. He carried it to the site with one hand. Because it's air-cooled and rated for -20°C, he plugged it in and got to work immediately. The portability and wide operating temperature range turned a potential multi-day crisis into a two-hour fix. John said that single event proved the machine's ROI.

Real-World Adaptability: X1 vs. Traditional Systems

| Feature | Redshift X1 Handheld Welder | Traditional Compact Welder |

|---|---|---|

| Portability1 | 10kg (22 lbs), single-person carry | 50kg - 100kg+, requires a cart or team lift |

| Cooling System | Integrated Air-Cooling2 | Requires a separate, heavy water chiller |

| Operating Temperature | -20°C to 45°C (-4°F to 113°F) | Narrow range, struggles in extreme hot or cold |

| Setup Time | Under 5 minutes | 15-30 minutes, including water lines |

The Redshift X13 isn't just a tool for welding thin sheets; it's a versatile problem-solving platform4 for your entire operation.

Conclusion

The challenge of welding thin metal sheets (0.1mm-1.8mm) is not a matter of skill alone; it's a matter of science. As research shows, success depends on mastering heat input, ensuring a zero-gap fit, and achieving a high spot-overlap rate. The Redshift X1 Handheld Laser Welder transforms these complex principles into a simple, three-step process. With intuitive knob controls, it gives you precise command over heat, while its design makes achieving a perfect, continuous seam straightforward. Coupled with its rugged 10kg portability and all-weather air-cooling, the X1 is the definitive tool for mastering thin-sheet welding in any environment.

Relate

-

Learn why portability can significantly impact your welding projects and overall productivity. ↩

-

Discover how Integrated Air-Cooling enhances performance and efficiency in welding applications. ↩

-

Explore this link to understand how the Redshift X1 can enhance your welding operations and solve various challenges. ↩

-

Discover insights on how versatile platforms can streamline processes and boost productivity in your operations. ↩