As a purchasing manager, you specify adhesive-backed Velcro for a new product line. The production team starts running the job on their CO2 laser, and everything seems fine. But soon, the calls start coming in. The laser is down, again. The cuts are getting imprecise, and there's a sticky film covering the machine's lens and guide rails. Your team is frustrated, production schedules are slipping, and you're left wondering if you bought a faulty batch of material or if the expensive laser cutter just can't handle the job.

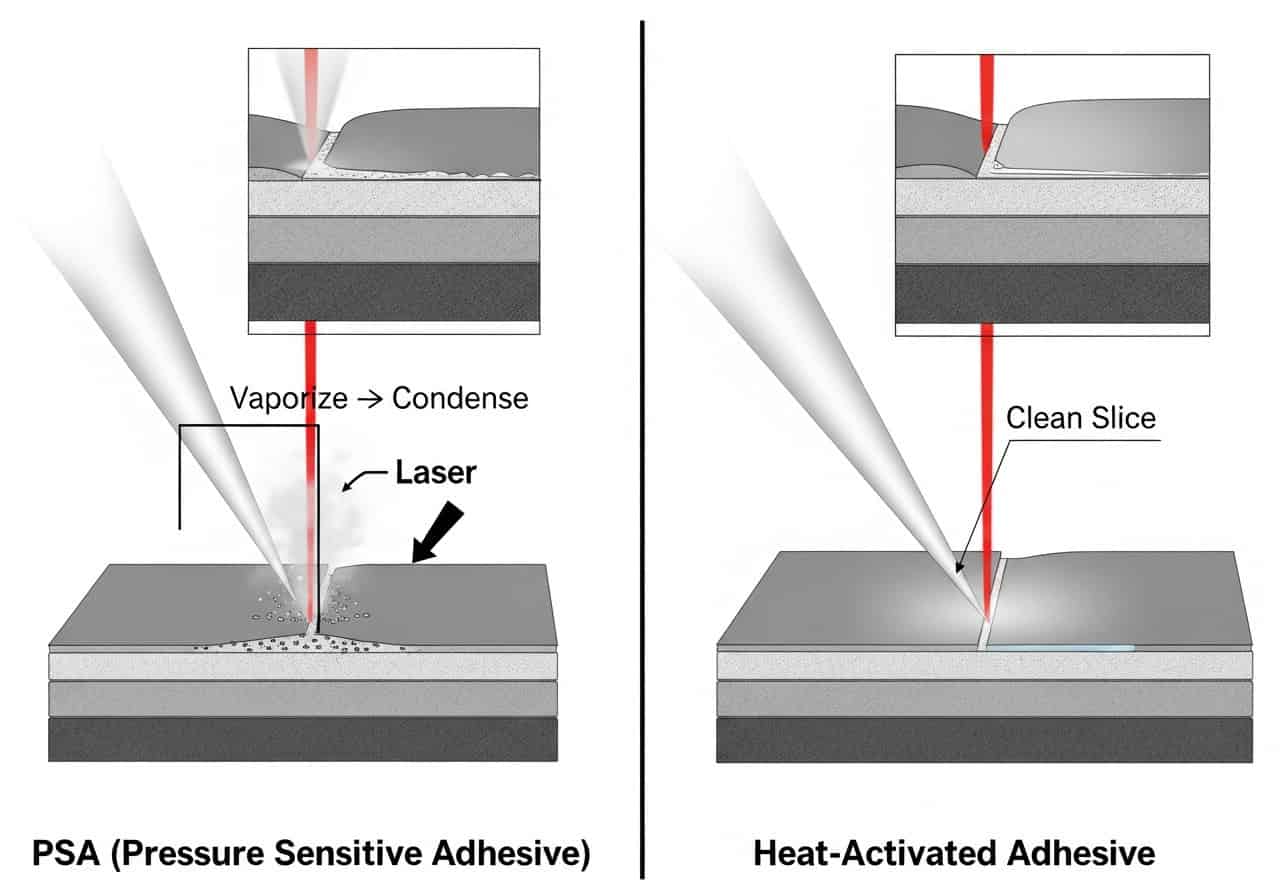

The secret to successfully laser cutting adhesive-backed Velcro isn't about the laser's power or the quality of the hook-and-loop material. The single most critical variable is the type of adhesive backing. Standard pressure-sensitive adhesives (PSAs) vaporize under the laser's heat and re-condense as a sticky residue, fouling the machine's optics and causing downtime. The solution lies in specifying a laser-compatible, heat-activated adhesive that cuts cleanly without contaminating your equipment.

I’ll never forget a visit to a client who manufactured custom cases for medical equipment. They were trying to cut small, intricate shapes from adhesive-backed Velcro, and their production was at a standstill. The operator showed me the laser lens, and it was caked in a hazy, yellowish film. "We clean this three times a day, August," the manager told me, clearly frustrated. "The machine runs great for an hour, then the cut quality just dies." I asked to see the spec sheet for the Velcro they were ordering. Sure enough, it was a standard, general-purpose acrylic PSA. They were fighting a battle they couldn't win, not because of their machine, but because of a single line item on a purchase order. We switched them to a supplier with a heat-activated backing, and their problems vanished overnight.

How Can a CO₂ Laser Improve Velcro Cutting Precision?

Right now, you might be using die cutters or manual knives to process your Velcro. You're constantly dealing with the material fraying at the edges, and the hooks and loops can get crushed or distorted by the pressure of the blade. Over time, your cutting dies and knives get dull, leading to inconsistent results and requiring production downtime for replacement. Cutting complex curves or sharp corners is a slow, difficult process that produces a lot of waste material.

A CO₂ laser cutting system completely solves these problems. By using a focused beam of light, the laser cuts through the material without any physical contact. This non-contact process instantly melts and seals the synthetic fibers of the Velcro, creating a perfectly clean, durable, and fray-free edge. It eliminates tool wear entirely and allows you to cut any shape you can draw on a computer with perfect accuracy and repeatability, drastically improving both quality and production speed.

A CO₂ laser improves the precision of Velcro cutting by using a non-contact beam that melts and seals the material's edges, preventing fraying. This process avoids crushing the hook and loop fasteners and allows for the cutting of highly intricate designs with perfect consistency, a feat impossible to achieve with traditional mechanical cutting methods.

1. No More Fraying Edges

The laser's primary advantage is its ability to create a finished edge in a single step.

- The Laser Advantage: The heat from the laser beam cauterizes the nylon or polyester fibers as it cuts. This creates a smooth, sealed edge that won't unravel or fray during handling, sewing, or in the final application.

- The Mechanical Disadvantage: A blade physically tears through the woven material, leaving loose fibers. This requires a secondary finishing step like sewing or heat-sealing to prevent fraying, adding time and labor cost.

2. Eliminating Material Distortion

Because the laser never touches the Velcro, the structure of the fasteners remains perfect.

- The Laser Advantage: A non-contact cut means no pressure is applied to the material. The tiny hooks and soft loops are left completely intact, ensuring the fastening performance of the Velcro is not compromised.

- The Mechanical Disadvantage: Die cutting and crush cutting can flatten and damage the hooks and loops along the cut edge, which can weaken the product's grip strength.

3. Unmatched Design Complexity

The laser follows a digital path, giving you complete design freedom.

- The Laser Advantage: Cut circles, tight corners, internal windows, and logos with incredible precision. Switching between jobs is as simple as loading a new digital file, making it perfect for custom work and rapid prototyping.

- The Mechanical Disadvantage: Die-cutting is limited to one shape per tool, making it expensive and inflexible for custom jobs. Manual cutting of complex shapes is slow and inconsistent.

| Feature | CO₂ Laser Cutter | Mechanical Die Cutter |

|---|---|---|

| Edge Finish | Sealed, No Fraying | Raw, Prone to Fraying |

| Material Contact | None | Yes (Pressure Applied) |

| Fastener Integrity | Preserved | Can be Crushed/Damaged |

| Design Flexibility | Extremely High | Low (Fixed Shape) |

| Tool Wear | None | Die Requires Sharpening/Replacement |

Is All Adhesive Backing the Same for Laser Cutting?

You've sourced adhesive-backed Velcro to streamline your assembly process, assuming it would be a simple "cut and stick" operation. But your production floor is reporting that the laser is gumming up. There's a sticky residue all over the machine, the exhaust filters are clogging up at an alarming rate, and the time spent cleaning the laser's optics is destroying your production efficiency. You're starting to think that laser cutting adhesive-backed materials is just not a viable process.

The problem isn't the concept; it's the chemistry. Not all adhesives are created equal, and this is especially true when a laser beam is involved. A standard Pressure-Sensitive Adhesive (PSA) is designed to be sticky at room temperature. The laser's intense heat vaporizes this gooey adhesive, which then travels with the smoke and re-condenses as a sticky mess on every cool surface inside your machine. The solution is to use an adhesive designed for this process, like a heat-activated backing.

No, all adhesive backings are not the same for laser applications. Standard Pressure-Sensitive Adhesives (PSAs) have a low vaporization point and create sticky residue that contaminates laser optics and mechanics. For clean and efficient cutting, you must specify a laser-compatible adhesive, such as a heat-activated film or a high-temperature acrylic, which remains stable during the cutting process.

1. The Problem with Standard PSAs

These are the most common and least expensive adhesives, and they are the source of most laser-cutting issues.

- How They Work: PSAs are perpetually "tacky." They work by flowing into the microscopic pores of a surface to create a bond.

- Why They Fail: The laser's energy instantly turns this semi-liquid adhesive into a gas. This vapor doesn't just get pulled out by the exhaust; it coats the lens, mirrors, belts, and rails. The result is a loss of laser power, inaccurate cuts, and costly downtime for cleaning.

2. The Solution: Heat-Activated Adhesives

These are specifically designed for thermal processing.

- How They Work: A heat-activated adhesive is solid and non-tacky at room temperature (often called a "hot melt" film). It only becomes sticky when a specific activation temperature is reached, usually with a heat press after it has been cut.

- Why They Succeed: Because the adhesive is solid during the laser cutting process, the laser slices through it cleanly. It doesn't vaporize into a sticky gas. This means no residue, no fouled optics, and no unplanned downtime.

3. Another Good Option: High-Temperature Acrylic Adhesives

For some applications, you may need a PSA that can withstand the laser process better than standard versions.

- What They Are: These are specially formulated PSAs that use a different chemical composition designed to withstand higher temperatures before breaking down.

- When to Use Them: While not always as clean-cutting as a heat-activated film, a high-temperature acrylic is a significant improvement over a standard PSA. They are a good middle ground if a heat-activation step is not possible in your assembly workflow.

| Adhesive Type | Laser Cutting Performance | How it Works | Best For |

|---|---|---|---|

| Standard PSA | Poor (creates sticky residue) | Sticky at room temperature | General use, NOT laser cutting |

| Heat-Activated | Excellent (cuts cleanly) | Solid until heated post-cut | High-volume, clean production |

| High-Temp PSA | Good (reduced residue) | Resists heat better than standard PSA | When a PSA is required |

How Do You Solve Common Laser Cutting Challenges with Velcro?

You've selected a laser-compatible adhesive and you're ready to start production. However, you're still facing some issues. The edges of the Velcro are coming out a little too hard and melted, or maybe the laser isn't cutting cleanly through the material in some spots. Your team is struggling to find the right settings, and you're wasting material on test cuts. You need a reliable process, but the fine-tuning is proving to be a challenge.

The solution to these common problems lies in a systematic approach to your machine settings, focusing on three key areas: the power/speed balance, the air assist pressure, and the fume extraction efficiency. Getting these three elements working in harmony is the key to achieving a perfect, repeatable cut on any type of Velcro, with or without an adhesive backing. It’s less about finding one "magic number" and more about understanding how these settings interact.

To solve common challenges when laser cutting Velcro, start with high speed and low power, gradually increasing power until you achieve a clean cut. Use a medium setting for air assist to clear debris without over-cooling the edge. Most importantly, ensure your fume extraction system is powerful enough to pull all smoke and fumes down through the honeycomb bed, preventing residue from settling back onto the material.

1. Dialing in Power and Speed

This balance is fundamental to cut quality. The goal is to use the minimum amount of energy necessary.

- Challenge: The cut edge is too hard or melted, creating a thick, rigid bead.

- Solution: This is a sign of too much heat. Either increase your cutting speed or decrease your laser power. A faster cut transfers less thermal energy to the surrounding material, resulting in a softer, more flexible sealed edge. Always start fast and add power.

2. Optimizing Air Assist

Air assist is a jet of compressed air pointed at the cut line. It's crucial for quality and safety.

- Challenge: Small bits of melted material or smoke are leaving marks on the surface of the Velcro.

- Solution: Increase your air assist pressure. The air jet's job is to blow any molten debris away from the cut path and prevent flare-ups. This results in a cleaner top surface. However, be cautious: too much air can cool the cut too quickly and may prevent a perfect seal on very thin materials. A medium setting is usually best.

3. Ensuring Proper Fume Extraction

This is not just about safety; it's about cut quality.

- Challenge: You're getting a hazy discoloration or a "ghosting" effect on the material around the cut lines.

- Solution: This means fumes are settling back onto the material before they can be extracted. Ensure your fume extraction system is running at full power. A honeycomb table is essential here, as it allows the exhaust to pull the fumes down and away from the work piece immediately. If your extraction is weak, the smoke will linger and stain the fabric.

What Are the Sustainability Trends in Hook-and-Loop Materials?

As a purchasing manager, you are increasingly tasked with sourcing materials that meet corporate sustainability goals. You're looking for eco-friendly alternatives for every component in your products, but you're concerned that switching to a "green" Velcro might compromise its performance or make it incompatible with your laser cutting process. You need to find materials that are both environmentally responsible and fully compatible with your modern manufacturing methods.

The good news is that the hook-and-loop industry is actively innovating in this area. The most significant trends are the development of adhesives that are less reliant on harsh solvents and the introduction of hook-and-loop materials made from recycled or biodegradable polymers. These new materials are often designed with thermal processing in mind, making them excellent candidates for laser cutting, allowing you to improve your product's environmental footprint without sacrificing quality or production efficiency.

Sustainability trends in the fastener industry focus on two main areas: the use of eco-friendly, solvent-free adhesives and the development of hook-and-loop materials made from recycled polyesters (rPET) or biodegradable plastics. These materials are designed to be compatible with modern manufacturing, including laser cutting, enabling companies to meet environmental goals without compromising product performance.

1. Eco-Friendly Adhesives

The adhesive is often the least sustainable part of the product.

- The Shift: Manufacturers are moving away from traditional solvent-based adhesives, which can release volatile organic compounds (VOCs). The trend is toward water-based acrylic adhesives and solid hot-melt films.

- Laser Compatibility: This is a huge win for laser users. Hot-melt adhesives, as we've discussed, are ideal for laser cutting because they are solid at room temperature and produce no sticky residue. Many new eco-friendly PSAs also have higher thermal stability.

2. Recycled Materials (rPET)

This is the most common approach to making the fabric component more sustainable.

- What it is: The hook and loop fasteners are made from rPET, which is recycled polyethylene terephthalate—the same plastic used in water bottles.

- Laser Compatibility: Since rPET has similar thermal properties to virgin polyester, it cuts beautifully with a CO₂ laser. It produces the same clean, sealed, and fray-free edge you would expect from standard materials. This is a simple, drop-in replacement that can instantly improve your product's sustainability score.

3. Biodegradable and Bio-based Materials

This is the cutting edge of material science in the industry.

- What it is: Companies are experimenting with polymers derived from renewable resources like corn starch (PLA) or other materials designed to biodegrade under specific conditions.

- Laser Compatibility: These materials can often be laser cut1, but they require careful testing. Because they are designed to break down, their reaction to the intense heat of a laser can be different. It's crucial to work with your material supplier2 to get datasheets and recommended laser settings for these innovative new products.

Conclusion

We've seen that when it comes to laser cutting Velcro, the details matter immensely. While a laser offers unmatched precision and a perfect, sealed edge, the real key to a smooth and efficient production process lies in the adhesive backing. By understanding the chemical difference between a standard PSA and a laser-compatible, heat-activated adhesive, you can eliminate the frustrating and costly downtime caused by residue buildup. As a procurement professional, specifying the right type of adhesive is the single most impactful decision you can make. This ensures your production team can leverage the full speed and precision of their laser technology without fighting the machine.