As a purchasing manager, you see "multi-layer cutting" on a spec sheet and immediately calculate the potential throughput gains. You imagine doubling or tripling your output in a single pass, a massive boost to efficiency. But you’re also experienced enough to know that promises on paper often fail on the factory floor. You suspect there's a catch, a hidden problem that could turn that promised efficiency into a pile of expensive, unusable material.

Your machine might be able to cut multiple layers, but getting usable parts from every layer is a different challenge. The real key to successful multi-layer cutting isn't raw laser power; it's sophisticated process control. Without precise management of heat, airflow, and material stability, you risk melted-together fabrics and discolored paper. True success lies in mastering these variables to ensure the bottom layer is as perfect as the top one.

I remember a client in the garment industry who bought a high-power laser from another supplier, excited by its multi-layer cutting claims. They stacked ten layers of polyester, hit start, and expected a tenfold increase in output. Instead, they pulled out a single, fused brick of melted plastic. The intense heat, trapped between the layers, had welded the synthetic fabric together. They called me, frustrated, and I explained that they hadn't bought the wrong machine, they were just missing the real secret. Multi-layer cutting isn't about brute force. It's a delicate science of control. Let's explore what that really means for your production floor.

Why Is Laser Multi-Layer Cutting So Important?

You're under constant pressure to increase factory output without increasing costs. Every second saved on the production line translates directly to your bottom line. Stacking materials seems like the most logical way to boost throughput. But if this process creates a high rate of defects, you haven't actually gained anything. You've just created waste faster.

Multi-layer cutting is important because, when done correctly, it represents the single greatest leap in production efficiency for high-volume cutting tasks. By processing multiple sheets simultaneously, it multiplies output without multiplying machine time or labor. For industries making large quantities of identical parts—like apparel components, fabric samples, or paper craft kits—mastering this technique is the key to scaling production and achieving a significant competitive cost advantage.

For a manager like John, the importance of a process is measured in usable final parts, not just raw cycle time. This is where multi-layer cutting, when understood properly, truly shines.

1. The Multiplier Effect on Production

The most obvious benefit is throughput. Cutting four layers at once theoretically quadruples your output for the same amount of machine operating time. This is a massive leverage point for businesses that produce thousands of identical items, reducing the cost per part dramatically.

2. Consistency Across Batches

Once a multi-layer cutting process is dialed in, it produces highly consistent parts. The stack is held under uniform pressure, and the laser follows the exact same digital path every time. This reduces the part-to-part variation that can occur in single-layer cutting across multiple jobs.

3. Reduced Material Handling

Think about the labor involved. Instead of loading, cutting, and unloading a single sheet 10 times, your operator loads one stack, runs one job, and unloads one finished set. This huge reduction in material handling frees up your team for more value-added tasks like quality control and packaging.

Impact on Overall Equipment Effectiveness (OEE)

| OEE Factor | Single-Layer Cutting | Mastered Multi-Layer Cutting |

|---|---|---|

| Availability | Lower (more time spent on setup) | Higher (less time on load/unload) |

| Performance | Lower (slower throughput) | Significantly Higher (multiplied output) |

| Quality | High but labor-intensive | High (consistent with less handling) |

What Are the Real Advantages of Multi-Layer Cutting?

You've seen the marketing claims: "cut 10x faster!" This sounds great, but your experience tells you there must be trade-offs. You're worried about sacrificing quality for speed. You suspect that the bottom layers won't be as clean as the top, leading to high rejection rates that wipe out any time savings.

The real-world advantage isn't just speed, it's efficient scalability. A properly configured multi-layer process doesn't compromise on quality. The primary advantages are a drastically lower cost-per-part and a shorter lead time for large orders. By mastering heat management and material handling, you can produce large quantities of identical, high-quality parts faster than any other method, making your operation far more competitive for high-volume contracts.

The advantages aren't automatic. They are the result of overcoming specific technical hurdles. Here is what separates a successful operation from a failed one.

1. Challenge: Heat Entrapment & Fusion

When a laser vaporizes material, it creates super-heated gas. In a stack, this gas gets trapped between layers. With synthetic fabrics like polyester, this heat is enough to melt the edges, welding the layers together.

Solution: Laser Pulsing. Instead of a continuous beam, the laser is pulsed rapidly. This gives the material a microsecond to cool between pulses, reducing overall heat buildup and preventing fusion.

2. Challenge: Debris, Smoke, and Discoloration

Vaporized material turns into smoke and debris. Trapped in a stack of paper or light-colored fabric, this smoke can condense back onto the lower layers, causing ugly brown or yellow stains along the cut edge.

Solution: Optimized Air-Assist. A powerful, focused jet of compressed air travels with the laser head, blowing directly into the cut. This forcefully ejects smoke and debris from between the layers before they can cause discoloration, ensuring a clean cut top to bottom.

3. Challenge: Material Shifting

Even a tiny shift of a single layer during cutting will ruin the entire stack. The force of the air-assist or vibrations from the machine can easily cause layers to move if they are not secured.

Solution: Strong Vacuum Hold-Down. A powerful vacuum system pulls air down through a perforated machine bed. This creates suction that pins the entire stack of material firmly in place, preventing any movement during the cutting process.

The Physics of Success

| Problem | Failed Approach (More Power) | Successful Approach (Control) |

|---|---|---|

| Fabric Layers Fusing | Increases power, melts material faster. | Pulse the laser beam to manage heat input. |

| Paper Edges Burning | Cuts faster, but heat still discolors. | Use strong air-assist to clear smoke. |

| Layers Misaligning | Ignores the problem, results in defects. | Use a powerful vacuum table to fix the stack. |

What Are the Main Applications for This Technique?

You understand the theory, but you need to know where this actually provides a return on investment. You're trying to identify which parts of your production—or your clients' production—are the best fit for this advanced technique. It's not a universal solution, so knowing the ideal use cases is critical for making a smart purchase decision.

The best applications for multi-layer cutting are any high-volume production of identical, repeatable shapes from sheet materials. It excels in the apparel industry for cutting components like appliqués, pocket linings, and collars. In the promotional products space, it's perfect for fabric coasters and felt pennants. For paper goods, it's ideal for intricate wedding invitations, scrapbooking kits, and custom packaging inserts where thousands of identical items are needed.

This technique is a specific tool for a specific job: mass production of uniform parts. Here's a breakdown of the most profitable sectors.

1. Apparel and Textiles

This is the primary market. Cutting multiple layers of fabric for clothing patterns (sleeves, collars, panels) is a core application. It's also used for mass-producing appliqués and other decorative elements before they are embroidered or stitched. The key here is using the process controls to handle synthetic blends without fusion.

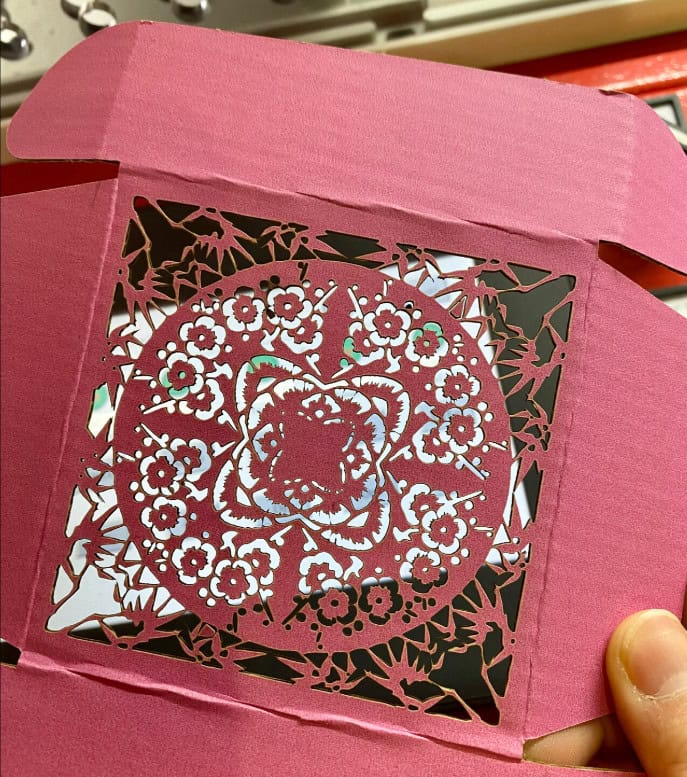

2. Paper Crafts and Stationery

Companies producing intricate wedding invitations, greeting cards, or scrapbook elements benefit immensely. A stack of high-quality cardstock can be cut in a single pass, producing hundreds of identical, clean-edged products ready for printing or packaging. Managing discoloration is the most critical factor here.

3. Industrial Gaskets and Filters

While not a fabric application, the same principle applies to cutting gaskets1 or filter media. Many industrial materials can be stacked and cut with precision, as long as the material doesn't fuse. This is a huge efficiency gain2 for automotive and manufacturing suppliers.

4. Promotional and Upholstery Goods

Think about cutting hundreds of coasters from felt, logos from twill for Heat-transfer, or upholstery fabric panels for furniture. These are perfect use cases where the shapes are repetitive and the volume is high.

Conclusion

Multi-layer cutting is far more than a simple bullet point on a machine's spec sheet. While the promise of multiplying throughput is alluring, achieving it requires a deep understanding of process control. The real-world challenges of heat fusion, discoloration, and material stability are not solved by more power, but by the sophisticated management of laser pulsing, air-assist, and vacuum hold-down. By shifting your perspective from buying a feature to mastering a process, you can unlock genuine, scalable efficiency and turn your laser into a true engine of high-volume production for your factory.

FAQs

Q1: My current laser struggles with multi-layer cutting, often melting the edges of synthetic fabrics. Is this a power issue?

A: Not necessarily. In fact, more power can make it worse. This issue, called "inter-layer fusion," is caused by trapped heat. The solution is better process control, specifically "laser pulsing," which gives the material microseconds to cool between laser bursts, preventing melting.

Q2: When I try to cut stacked paper, the bottom layers get stained brown. How do I prevent this?

A: That staining is caused by smoke and vaporized material settling on the lower layers. The fix is a powerful and well-aimed "air-assist" system. A strong jet of compressed air blows directly into the cut, forcefully ejecting debris before it can discolor the material.

Q3: Why do my layers shift during a multi-layer cut, ruining the whole stack?

A: Even small vibrations or the force of the air-assist can cause layers to move. The essential solution is a strong vacuum hold-down table. This system uses suction to firmly pin the entire stack of material to the machine bed, ensuring perfect alignment from top to bottom.

Q4: So, is multi-layer cutting more about the operator's skill than the machine's features?

A: It's a combination of both. You need a machine with advanced process controls (pulsing, air-assist, vacuum). But you also need the expertise to create the right "cutting recipe"—the specific power, speed, and frequency settings—for each material stack. This is where experience and support from your machine provider are critical.

Q5: Is there a limit to how many layers I can cut at once?

A: Yes, and it depends entirely on the material, its thickness, and the three key process controls (heat, airflow, stability). For thin polyester, it might be 8-10 layers. For thick cardstock, it might only be 3-4. The limit is reached when you can no longer guarantee a clean, unfused cut on the very bottom layer.

Q6: Does multi-layer cutting work for natural fibers like cotton as well as synthetics like polyester?

A: Yes, but the challenges are different. Natural fibers are less prone to melting but can be more susceptible to charring and discoloration, making aggressive air-assist even more important. Synthetics require a greater focus on laser pulsing to manage heat and prevent fusion.

Q7: Will multi-layer cutting slow down the laser's cutting speed?

A: To control heat, you may need to reduce the cutting speed slightly compared to a single layer. However, the massive gain in throughput from cutting multiple layers at once far outweighs any minor speed reduction. The overall "per-part" time is dramatically lower.

Q8: What are the best applications to get a high ROI from multi-layer cutting?

A: The best applications are high-volume, repeatable jobs. Think cutting apparel components (collars, pockets), fabric appliqués, batches of wedding invitations, industrial gaskets, or promotional items like felt coasters. The more identical parts you need, the higher the ROI.

Q9: Does the laser beam lose power as it cuts through the stack?

A: Yes, the focus and energy density of the beam degrade slightly with each layer it penetrates. This is another reason why there is a practical limit to the stack height and why a powerful, well-collimated laser source is still an important part of the equation.

Q10: What should I ask a supplier when evaluating their multi-layer cutting capabilities?

A: Go beyond the "how many layers" question. Ask them: "Show me your controls for laser pulsing to prevent fusion." "Demonstrate how your air-assist prevents scorching on the bottom layer." and "How powerful is your vacuum table for preventing material shift?" This tests their understanding of the real-world physics involved.