You're a production manager looking to upgrade your polyester cutting process. You pull up the spec sheets for two laser machines. Machine A boasts a higher cutting speed and more wattage. It seems like the obvious choice for maximizing output. But after a few weeks of running it, your team is constantly stopping production. The cuts are getting less precise, and the machine needs frequent, time-consuming cleaning. The promised speed has vanished, replaced by frustrating downtime. That "faster" machine is now the biggest bottleneck on your floor.

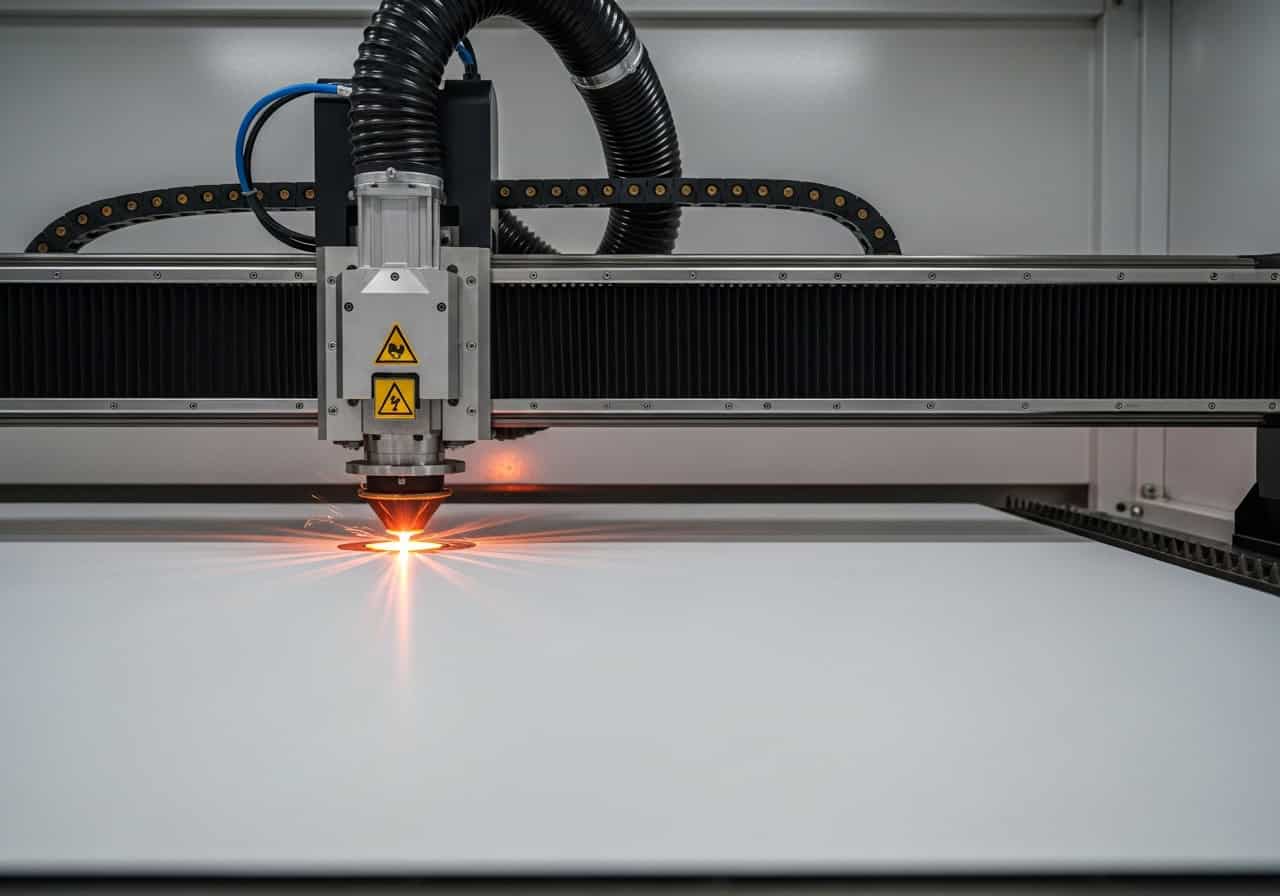

The true key to high-volume polyester cutting isn't the laser's top speed, but the power and design of its fume extraction system. When a laser vaporizes polyester, it creates a sticky, oily residue. This fume condenses on everything inside the machine, coating the optics and gumming up the motion system. An inadequate exhaust can't remove this byproduct fast enough, leading to degraded performance and constant downtime for cleaning. The real bottleneck is poor air quality, not machine speed.

I remember walking into a client's workshop a few years ago. They had bought one of the "fastest" machines on the market to cut polyester linings for industrial bags. But the machine was idle, and an operator was meticulously cleaning the lens and mirror with alcohol swabs. The manager was fuming. "We have to do this three times a day!" he told me. "The cuts start to get blurry after just an hour of work." I looked at their setup. They had a top-of-the-line laser connected to a small, underpowered shop fan. The problem wasn't the laser; it was the air. They were so focused on the speed of the cut that they completely overlooked the system needed to support it. This experience taught me a valuable lesson: for polyester, you buy the fume extractor first, and the laser second.

Why Choose a Laser Over a Knife for Cutting Polyester?

Your current process uses mechanical cutting, either with a drag knife or a die cutter. You're constantly dealing with frayed edges, which can lead to product defects or require an extra finishing step. Your team has to stop production to sharpen or replace blades, and complex, curved designs are slow and difficult to execute. These small inefficiencies add up, costing you time and material.

A laser cutter solves these exact problems directly at the source. It's a non-contact cutting method that uses a focused beam of light to vaporize the material. For a synthetic fabric like polyester, this process has a unique advantage: it melts and seals the edge as it cuts. This eliminates fraying entirely, improves the quality of the finished product, and simplifies your production workflow, saving you money on both labor and material waste.

Laser cutters are superior to traditional knives for cutting polyester because they produce a perfectly sealed, fray-free edge in a single pass. The non-contact process also eliminates tool wear, and the digitally controlled beam can cut highly intricate patterns with a level of speed and precision that mechanical methods cannot match.

1. Perfectly Sealed Edges

This is the laser's number-one advantage with synthetics.

- The Laser Edge: The intense heat from the laser beam instantly melts and fuses the polyester fibers along the cut line. This creates a clean, smooth, and sealed edge that will not unravel or fray. It's a cut and finish in one step.

- The Knife Edge: A physical blade pushes its way through the fabric, severing the fibers. This leaves a raw edge where the woven threads are prone to coming apart, especially during handling or sewing.

2. No Tool Contact or Wear

The laser never physically touches the material.

- The Laser Edge: Since there is no blade, there is nothing to sharpen or replace. The laser delivers consistent cut quality from the first piece to the ten-thousandth. There's no risk of the blade dragging or distorting delicate or stretchy polyester fabrics.

- The Knife Edge: Blades get dull. A dull blade can snag or pull the fabric, leading to inaccurate cuts. Production must be stopped regularly to change blades, which creates downtime and adds to your consumable costs.

3. Unmatched Design Freedom

The laser is controlled directly by a computer, like a printer.

- The Laser Edge: You can cut incredibly complex shapes, sharp corners, and tiny internal details with perfect repeatability. Switching from one design to another is as simple as opening a new file. This is ideal for custom work and rapid prototyping.

- The Knife Edge: Die cutters are limited to a single shape per die, making them inflexible for custom orders. Drag knives struggle with sharp corners and very small details, often needing to slow down significantly, which hurts productivity.

| Feature | Laser Cutter | Knife / Die Cutter |

|---|---|---|

| Edge Quality | Sealed, no fraying | Raw, prone to fraying |

| Tool Wear | None | Blades dull and need replacement |

| Design Complexity | Excellent | Limited |

| Material Contact | No | Yes |

| Setup Time | Minimal (load file) | High (die change, blade prep) |

What Settings Are Crucial for a Perfect Polyester Cut?

So, you've chosen a laser, but your results are inconsistent. Some cuts are perfect, but others leave a hard, melted bead along the edge or, even worse, don't cut all the way through. You're stuck in a frustrating loop of tweaking power and speed settings, wasting expensive material with every failed test. You need a reliable, repeatable process, not a guessing game.

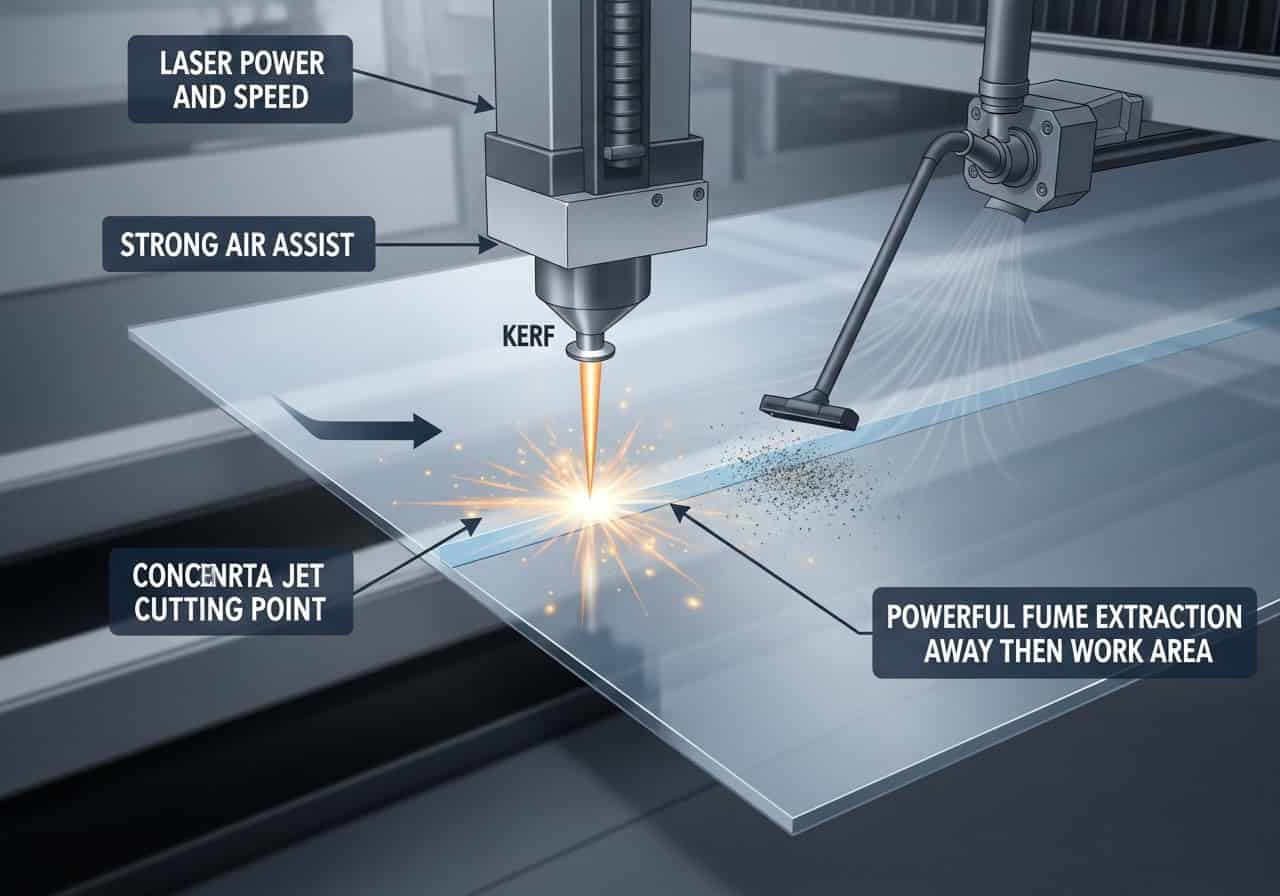

The secret to a perfect polyester cut goes beyond just the two main settings of power and speed. The key lies in managing the molten material and the fumes. For a clean, soft cut, you need the right amount of Air Assist to blow the molten polyester away from the cut path before it can form a hard bead. Even more importantly, you need powerful Fume Extraction to instantly remove the sticky vapor before it can settle back onto the material or the machine's components.

For a perfect polyester cut, you must balance three critical elements: laser power and speed to cleanly vaporize the material, strong air assist to clear molten debris from the kerf, and a powerful fume extraction system to remove oily residue, ensuring both cut quality and machine reliability.

1. The Power and Speed Balance

This is your starting point. The goal is to use the highest speed and lowest power possible that still achieves a clean cut.

- Too much power or too little speed: This puts excessive heat into the material, causing a thick, hard melted edge and increasing the amount of sticky fume.

- Too little power or too much speed: The laser won't cut all the way through the fabric, which is a failed cut.

- The Sweet Spot: A fast-moving, low-power beam that just cleanly severs the fibers. Start fast and gradually increase power until you get a consistent cut.

2. The Critical Role of Air Assist

This is what determines the quality of your edge. Air assist is a stream of compressed air directed at the cutting point.

- Without Air Assist: The molten polyester just sits in the cut path, re-solidifying into a hard, raised bead. This can be undesirable for products that need to be sewn or have a soft feel.

- With Air Assist: The jet of air blows the molten material down and away from the fabric. This action cools the edge quickly and prevents the bead from forming, resulting in a much softer and cleaner finish. It also helps protect the laser's lens from rising fumes.

3. Why Fume Extraction is Non-Negotiable

This is the setting that ensures your long-term success. As we established, polyester fumes are oily and destructive.

- Inadequate Extraction: The sticky vapor hangs in the air inside the machine. It coats the lens and mirrors, causing the laser beam to lose focus and power. This leads to inconsistent cuts and eventually requires you to stop and clean the optics. The residue also gums up the belts and guide rails, causing jerky movements and precision errors.

- Powerful Extraction: A strong, high-volume exhaust system creates negative pressure, instantly pulling all fumes down and out of the machine. This keeps your optics clean, protects your motion system, and ensures your laser performs consistently all day long.

What Machine Features Matter Most for Polyester Applications?

You are convinced a laser is the right tool and you understand the importance of fume extraction. Now you're looking at machines, and the options are overwhelming: different wattages, bed sizes, and features. You are worried about making the wrong choice—either overspending on a machine with features you'll never use or, worse, buying a system that can't keep up with your production demands for applications like filters, apparel, or upholstery.

The key is to focus on a holistic system designed for fabric, not just raw power. For polyester, the most important features are not just the laser tube wattage, but a system built around efficient workflow and fume management. You need a suitable worktable that supports the fabric and allows airflow, a pass-through design if you work with rolls, and, above all, an integrated fume extraction system that is properly matched to the size of the machine.

The most critical machine features for cutting polyester are a high-volume fume extraction system, a honeycomb or slatted worktable for material support and airflow, and a laser power of 60-100W, which is sufficient for most fabric applications. For roll-fed production, a pass-through door and an auto-feeder system are essential for efficiency.

1. The Fume Extraction System (Revisited)

This is the single most important component of your system. It's not an accessory; it's the foundation of reliable production.

- What to look for: A dedicated, high-CFM (Cubic Feet per Minute) blower unit. The exhaust system's capacity should be matched to the volume of your machine's enclosure. A larger machine requires a more powerful extractor. Look for robust ducting and a system that pulls air evenly across the entire work area.

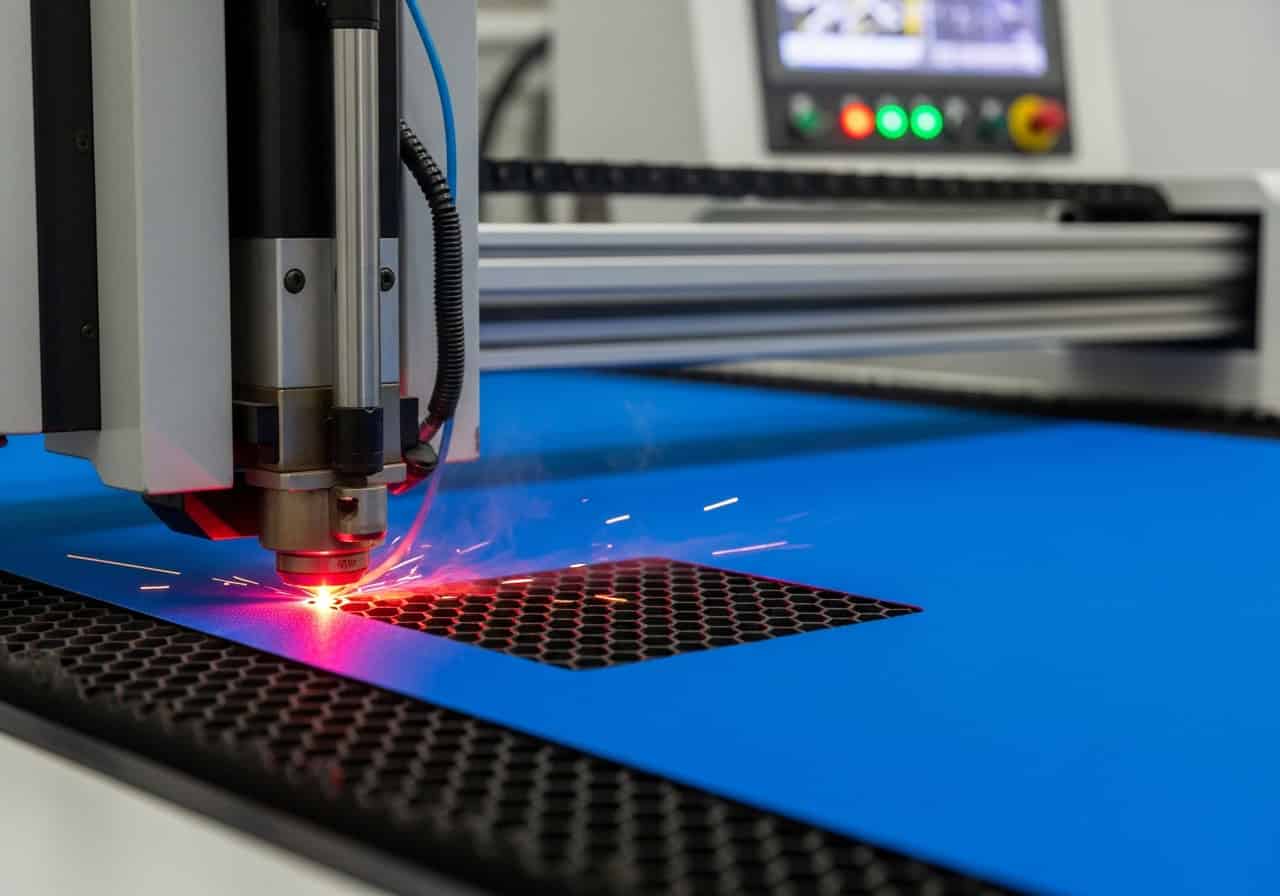

2. The Right Worktable

The surface your polyester lies on is crucial for cut quality.

- Honeycomb Bed: This is the most popular choice for fabric. It provides a flat, stable support surface with thousands of small openings. This design allows the laser beam to pass through the material cleanly and lets the air assist and fume extraction pull air from below, preventing backside burning or marking.

- Slatted Bed: Also a good option, especially for thicker or more rigid polyester materials. The principle is the same: support the material while allowing air and debris to fall away.

3. Matching Wattage and Bed Size to Your Application

Bigger is not always better. You need the right tool for the job.

- Laser Power (Wattage): For most polyester fabrics used in apparel, filtration, and signage, a CO2 laser tube between 60W and 100W is the sweet spot. This range offers more than enough power to cut quickly without requiring excessive cooling or a huge power supply. You only need higher wattage (130W+) for very thick industrial felts or multi-layer cutting.

- Bed Size: This should be dictated by your material size. If you work with large rolls of fabric for upholstery or banners, you'll need a large format machine1 (e.g., 1300x2500mm). If you cut smaller pre-cut pieces for apparel panels, a smaller bed (e.g., 900x600mm) will be more efficient. A machine with front and back pass-through doors2 is essential if you ever plan to work with material larger than the bed itself.

Conclusion

When it comes to laser cutting polyester, we've learned that looking past the flashy top-speed numbers on a brochure is essential. The real measure of a production-ready system lies in its ability to manage the byproducts of the cutting process. The sticky, oily residue from vaporized polyester is the true enemy of uptime. By prioritizing a powerful and efficient fume extraction system, you protect your machine's optics and mechanics, ensuring consistent, precise cuts hour after hour. This focus on the entire system—from air assist to the worktable—is what transforms a laser cutter from a simple tool into a reliable manufacturing solution.