You're trying to add beautiful, intricate logos to leather goods, but the results are disappointing. The marks are faint, inconsistent, and lack that rich, dark contrast you see on premium products. You've spent hours adjusting your laser's power and speed, blaming the machine and wasting expensive hides, but nothing seems to work. The frustration is building, and you're starting to think high-quality engraving is out of reach.

The secret to a perfect laser engraved leather mark lies not in the laser's settings, but in the leather's chemical composition. The key is to use vegetable-tanned leather. This type of leather is rich in natural tannins, which caramelize under the laser's focused heat to produce a deep, dark, and beautifully contrasted mark. In contrast, chrome-tanned leather lacks these tannins and will only produce a faint, low-quality result.

This isn't just theory; I've seen it cost people dearly. I once worked with a startup making high-end custom belts. They had a great design and a powerful laser but couldn't get their logo right. The engraving was a pale, ugly grey. They were convinced their new laser was faulty. When I visited their workshop, I didn't look at the machine first. I picked up a piece of their leather—it was soft and supple, typical of a chrome-tanned hide used for apparel. I asked one question: "Can you tell me about the tanning process?" That question changed everything. We swapped their material for a piece of vegetable-tanned leather, and the very first test produced a perfect, crisp, dark brown logo. They hadn't bought the wrong machine; they had simply sourced the wrong material.

Why Isn't All Leather the Same for Lasers?

You source materials for a living. You look at leather based on its grade, thickness, and finish, assuming that for a laser, "leather is leather." This assumption is the root of most failed engraving projects. It leads to wasted material, inconsistent quality, and even potential safety hazards, making you look bad and costing your company money.

Not all leather is the same because the tanning process, which turns raw hide into a durable material, uses different chemicals. Vegetable-tanned (veg-tan) leather uses natural tannins from tree bark. Chrome-tanned leather uses chromium salts. The laser's heat reacts with these specific chemicals, and only the natural tannins in veg-tan leather produce the desired dark, "caramelized" effect.

Understanding the chemistry is the key to mastering the process. A purchasing manager like John needs to be able to specify the correct material from the start.

1. Vegetable-Tanned Leather: The Ideal Canvas

This is the traditional method of leather tanning. The natural tannins are organic compounds that essentially "cook" under the laser's heat.

- Reaction: The laser's energy causes the tannins to caramelize, a process similar to browning sugar.

- Result: A rich, dark brown, and permanent mark that is slightly debossed (sunken) into the surface. The contrast is excellent.

- Best For: Wallets, belts, patches, coasters, keychains—anything where a high-contrast, classic "branded" look is desired.

2. Chrome-Tanned Leather: The Problem Material

This is the most common tanning method for upholstery, fashion, and apparel due to its softness and color stability.

- Reaction: The chromium salts do not caramelize. The laser simply ablates (removes) the dye and top layer, leaving a faint mark.

- Result: A low-contrast, often greenish-grey mark with minimal depth. Worse, heating chromium compounds can release potentially harmful fumes.

- Best For: Cutting only. It can be cut cleanly, but it is not recommended for high-quality engraving.

Material Comparison: Veg-Tan vs. Chrome-Tan for Lasers

| Feature | Vegetable-Tanned Leather | Chrome-Tanned Leather |

|---|---|---|

| Engraving Result | Rich, dark, high contrast | Faint, pale, low contrast |

| Key Chemical | Natural Tannins | Chromium (III) Salts |

| Laser Reaction | Caramelization | Surface Ablation |

| Ideal Use Case | Engraving & Cutting | Cutting Only |

| Safety Note | Standard fumes | Potential harmful chromium fumes |

What Are the Advantages of Using a Laser on Leather?

You're used to traditional leatherworking methods like stamping, embossing, and die-cutting. These require expensive custom tools, long setup times, and are prone to human error. You see them as slow and costly, especially for custom jobs or small production runs, and you're looking for a more efficient and flexible alternative.

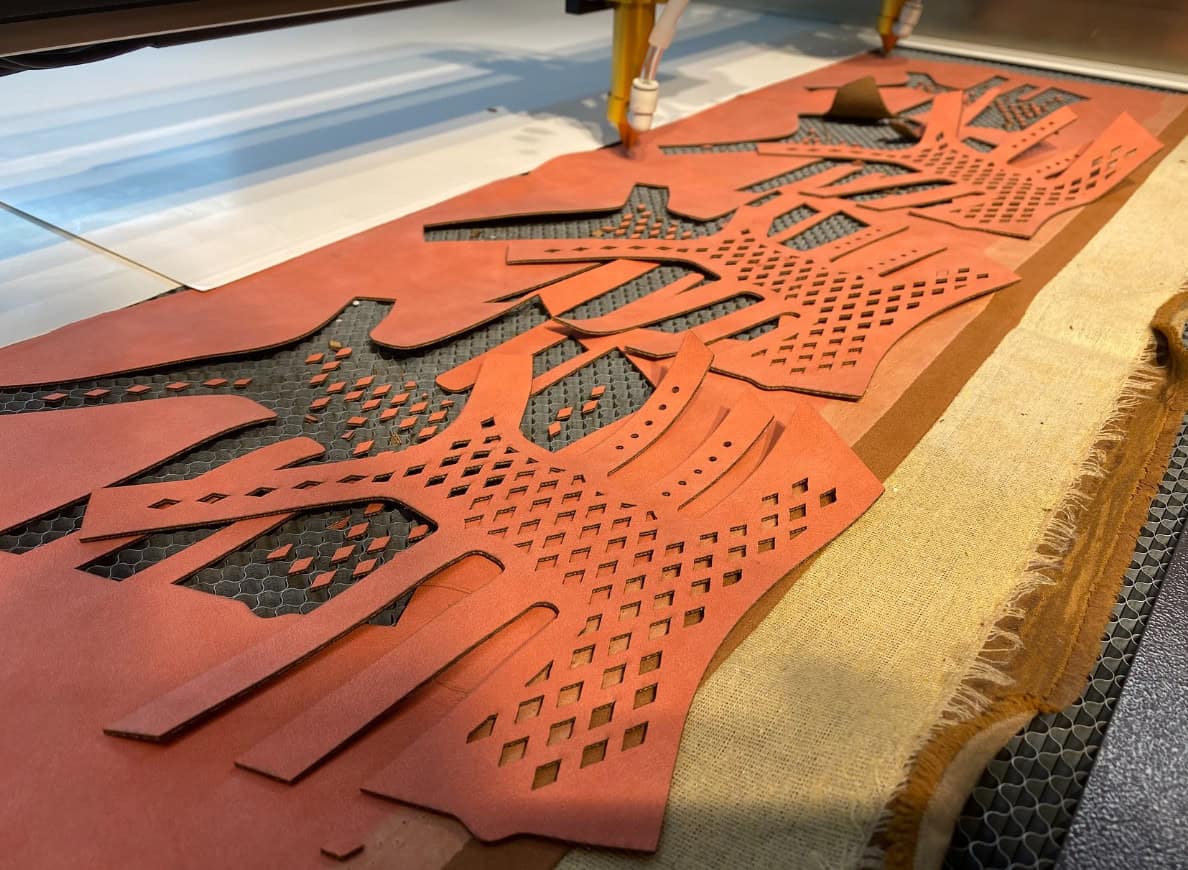

The primary advantage of laser engraving leather is its incredible precision and versatility without physical contact. A laser can create extremely detailed designs, sharp text, and intricate patterns that are impossible with a physical stamp. Since there are no dies or tools to create, you can switch between designs instantly, making it perfect for custom orders, prototyping, and small-batch production with zero setup costs.

Beyond the basic benefits, the laser process introduces a level of industrial efficiency to a craft material.

1. Unmatched Precision and Detail

A traditional steel stamp has physical limitations on its level of detail. A laser beam's spot size is tiny (often less than 0.1mm), allowing it to reproduce vector art and even grayscale images with photographic quality. This opens up entirely new design possibilities.

2. Non-Contact Process

Because only a beam of light touches the material, there is no tool wear. You'll never need to replace a dull stamp. This also means the leather is not subjected to any mechanical stress, so there's no risk of deforming or stretching the material, which is especially important for thin or delicate hides.

3. Repeatability and Consistency

Once you have the settings dialed in for a specific type of leather, a laser will produce the exact same result every single time. This industrial-level consistency is crucial for branding and product lines where every item must look identical. Human error is completely removed from the marking process, ensuring superior quality control.

What Are the Best Applications for Laser Engraved Leather?

You might think of laser engraving on leather as a niche process, limited to small items like keychains or promotional trinkets. This narrow view prevents you from seeing the broader commercial potential. You're missing opportunities to add high-value customization to a wide range of products that your company either already makes or could easily expand into.

The applications are incredibly versatile, spanning from personalized consumer goods to high-end industrial branding. Popular uses include custom-engraved wallets, belts, and watch straps; branded patches for hats and jackets; personalized journals and portfolios; bespoke menu covers for restaurants; and unique corporate gifts. For industrial use, lasers can precisely cut gaskets and mark serial numbers on leather components.

A laser machine is not a single-task tool; it's a gateway to multiple markets.

1. Fashion and Apparel Personalization

This is a huge market. Lasers allow you to offer on-demand customization.

- Patches: Engrave and cut custom leather patches for hats, jeans, and bags.

- Direct Engraving: Add monograms to wallets, logos to belts, and intricate patterns to footwear.

- Prototyping: A fashion designer can test a new design on a leather good in minutes, without waiting weeks for a stamp or die.

2. Corporate Branding and Gifts

Leather communicates quality and longevity, making it perfect for corporate branding.

- Promotional Items: Go beyond pens. Offer engraved leather portfolios, luggage tags, and mousepads.

- Office Decor: Create custom signage, desk sets, and coasters with the company logo.

3. Hospitality and Events

Thematic branding on leather adds a touch of class.

- Restaurants: Engraved menu covers, coasters, and bill presenters.

- Events: Personalized leather place settings or gift tags for weddings and corporate events.

How Do You Overcome Common Laser Engraving Issues?

You've selected the right veg-tan leather, but you're still facing problems. The engraving is surrounded by a dark, sooty residue, or the results are uneven across different parts of the same hide. You're frustrated because you did the most important part right, but the final quality is still not meeting your standards.

The most common issues are soot or residue on the surface and inconsistent engraving depth. Soot is easily solved by applying a layer of transfer mask or painter's tape to the leather before engraving; the laser engraves through the tape, which is then peeled off, taking all the residue with it. Inconsistency is solved by running small test grids on a scrap piece to fine-tune power and speed settings for that specific hide.

Even with the right material, a little process control goes a long way.

1. Eliminating Soot and Residue

Soot is the vaporized leather settling back onto the surface. Preventing it from sticking is the best solution.

- Masking: Applying a medium-tack paper transfer mask is the professional standard. It protects the surface, resulting in an exceptionally clean finish.

- Cleaning: For unmasked leather, a gentle wipe with a cloth dampened with denatured alcohol can remove some residue, but be careful not to damage the leather's dye.

2. Managing Inconsistent Density

Leather is a natural material, and its density can vary across the hide. The area over the spine might be denser than the belly.

- Test, Test, Test: Never run a final product without first testing your settings on a scrap piece from the same hide.

- Power Adjustment: If you notice engraving is too light in certain areas, you may need to slightly increase the power or decrease the speed. A small change can make a big difference.

3. Preventing Over-Burning

It's tempting to use too much power to get a dark mark. This can lead to a brittle, overly-charred result. The goal is caramelization, not incineration.

- Start Low: Begin with lower power1 and higher speed settings and gradually increase the power until you achieve the desired dark brown color. The best marks are often achieved with multiple passes2 at lower power rather than one pass at high power.

Conclusion

The secret to exceptional laser engraving on leather isn't a secret at all; it's a matter of material science. The romantic idea of "branding" gives way to the practical reality of a chemical reaction. Success is almost entirely determined before the machine is even turned on, by choosing vegetable-tanned leather for its rich tannin content. Once you start with the right material, the laser's precision, repeatability, and versatility transform a traditional craft into a modern manufacturing process, opening doors to endless customization and high-value product opportunities.

FAQs

Q1: What is the most important factor for achieving a high-quality laser engraving on leather?

A: The leather's tanning process is the most critical factor. For a rich, dark mark, you must use vegetable-tanned (veg-tan) leather, as its natural tannins caramelize under the laser's heat.

Q2: Why does vegetable-tanned leather engrave well?

A: Veg-tan leather is processed with natural tannins from plants. The laser's heat causes these tannins to undergo a chemical reaction called caramelization, which produces a consistent, dark brown, high-contrast mark.

Q3: Why doesn't chrome-tanned leather engrave well?

A: Chrome-tanned leather is made using chromium salts, which do not caramelize. The laser simply ablates the surface dye, resulting in a faint, low-contrast mark. It can also release potentially harmful fumes.

Q4: Can I laser cut chrome-tanned leather?

A: Yes. While it is not recommended for high-quality engraving, chrome-tanned leather can be laser cut very cleanly and precisely. The main issue is with the quality and safety of the engraving process.

Q5: How can I prevent soot or burn marks around my engraved design?

A: The best method is to apply a paper transfer mask (or painter's tape) over the leather surface before engraving. The laser cuts through the mask, which you then peel off, taking all soot and residue with it for a clean finish.

Q6: Is the laser just burning the leather?

A: No, it's more precise. On the correct type of leather (veg-tan), it's a controlled thermal reaction—caramelization—not just crude burning. Using too much power will cause charring, which should be avoided.

Q7: How do I get consistent results on a single piece of leather?

A: Leather is a natural material with varying density. Always perform a small test grid on a scrap piece from the same hide to dial in the perfect power and speed settings before running your final design.

Q8: What are the main advantages of a laser over a traditional leather stamp?

A: A laser offers superior precision for intricate designs, zero tool wear, and instant changeovers between different designs. This makes it ideal for customization, prototyping, and ensuring perfect consistency across products.

Q9: Besides wallets and belts, what are some other applications for laser engraved leather?

A: Common applications include branded patches for apparel, custom journal covers, high-end restaurant menus, corporate gifts like portfolios, and personalized luggage tags. The possibilities are vast.

Q10: Can I create different shades or depths when engraving leather?

A: Yes. By adjusting the laser's power and speed settings (a process called grayscale engraving), you can achieve different depths and shades of brown, allowing you to engrave detailed images and create subtle effects.