You've seen the beautiful, crisp designs laser engraved on felt and want to bring that premium look to your products. So you buy some high-quality, natural wool felt and run your first test. The result is a disaster. Instead of a clean mark, you get a charred, smelly mess, and the edges are burnt and irregular. You're frustrated, thinking the process is too difficult or that you've been misled about what lasers can do.

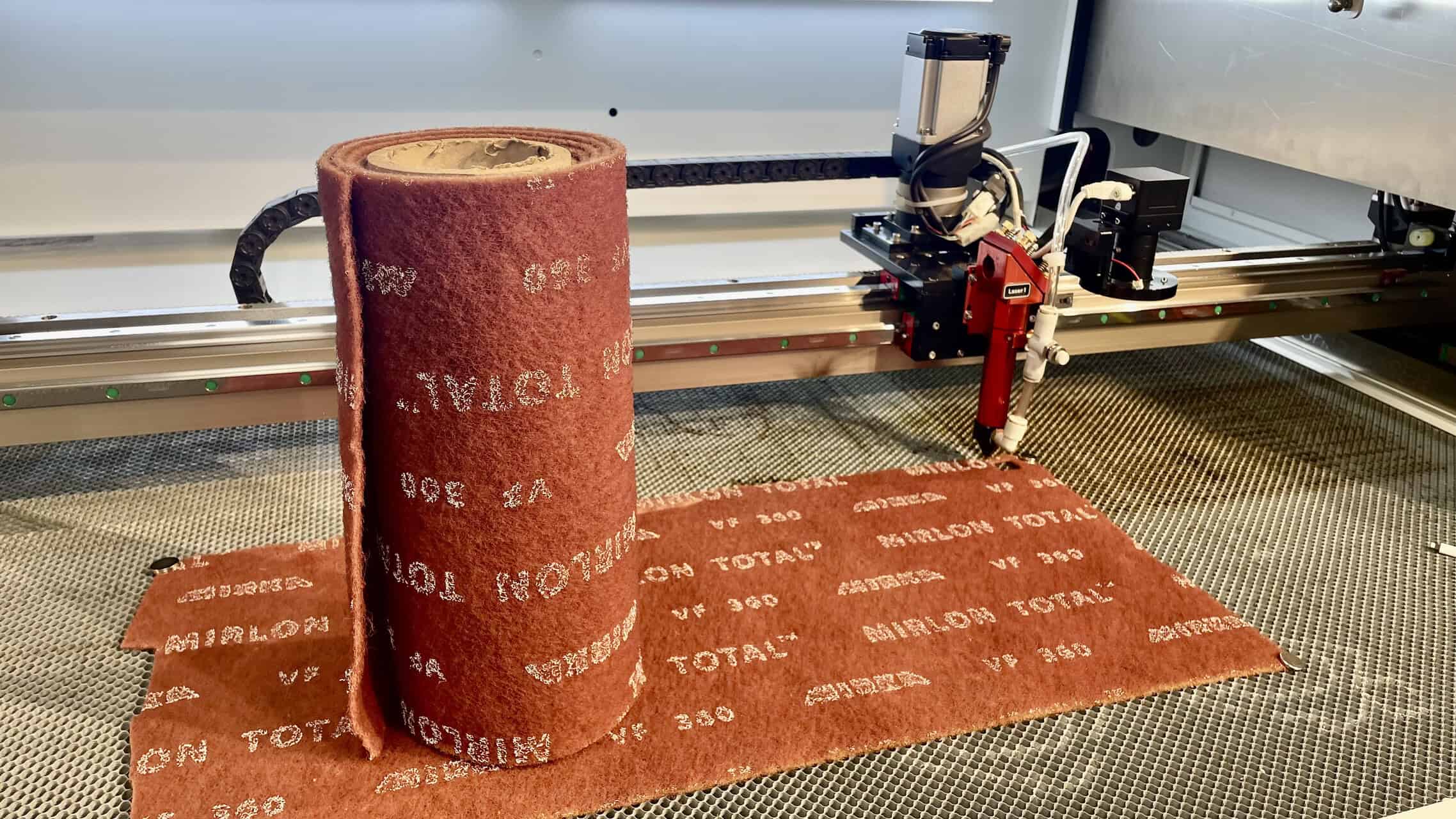

The secret to perfect laser results on felt has nothing to do with "engraving." The process is actually a precise thermal reaction that melts and fuses the fibers of synthetic felt, like those made from PET plastic. The key is using the right material—synthetic, not natural wool. This understanding transforms the laser from a simple marking tool into a highly efficient production machine that cuts and seals the edges in a single, clean step.

I remember a client working on high-end packaging inserts for luxury electronics. They insisted on using 100% natural wool felt for its premium feel. We ran a test, and their whole workshop ended up smelling like burnt hair for a day. The mark was awful. I explained that we weren't engraving wood; we were trying to melt fibers. We switched to a high-density PET felt that felt nearly identical. The laser created a perfect, clean depression with sealed edges. They realized the "secret" wasn't the machine—it was the industrial process of melting a polymer, which meant no fraying, ever. It completely changed their manufacturing approach.

What is Laser Engraving on Felt, Anyway?

You hear the term "laser engraving felt" but can't picture how it works. Engraving carves away material like wood or stone, so how can a laser cleanly mark a soft, fibrous material without just burning a hole through it? This confusion makes you hesitant to explore the process, and you might be missing out on a huge opportunity for your business.

Laser engraving on felt is a non-contact process where a focused laser beam, typically from a CO₂ laser, melts the surface of synthetic felt. Instead of vaporizing material to create depth, it fuses the plastic fibers together. This creates a darker, slightly debossed mark with a smooth, sealed texture. It isn't engraving in the traditional sense; it's a controlled thermal transformation of the material itself.

Understanding the process at a material level is what separates amateurs from professionals. It's not magic; it's materials science.

1. It's a Thermal Reaction, Not Ablation

When a laser engraves wood, it aDblates (vaporizes) material. With synthetic felt (like PET or acrylic), the laser's energy is absorbed, heating the polymer fibers just past their melting point. The fibers liquefy and fuse together, then re-solidify into a smooth, slightly compressed surface. This is what creates the mark.

2. The Critical Role of Synthetic Fibers

This process only works because common craft and industrial felt is made from plastic. Polyethylene terephthalate (PET), the same material used in water bottles, is a popular choice. Natural wool felt, on the other hand, is a protein fiber (keratin). It doesn't melt; it just chars and burns, producing a bad smell and an inconsistent, brittle mark.

3. Synthetic vs. Natural Felt: A Clear Divide

For any purchasing manager, knowing your material is the first step to success. The difference between wool and PET felt in a laser process is night and day.

| Feature | Synthetic PET Felt | Natural Wool Felt |

|---|---|---|

| Laser Reaction | Melts and fuses cleanly | Chars, burns, and smolders |

| Mark Quality | Smooth, consistent, debossed | Brittle, inconsistent, sooty |

| Edge Finish | Sealed and no-fray | Burnt and crumbly |

| Smell | Minimal (like melting plastic) | Strong (like burnt hair) |

| Best Use | Laser cutting and marking | Traditional crafts (sewing) |

What Are the Applications of Laser Engraving on Felt?

You see felt as a low-cost craft material, suitable for kids' projects but not for serious industrial or commercial products. This limited view means you're overlooking its potential for creating high-value, innovative items. Your competitors might be leveraging felt's unique properties for modern applications while you're stuck with more traditional, expensive materials.

Laser-cut and engraved felt is used across numerous industries to create high-value products. Its applications range from functional B2B solutions like custom acoustic wall panels and protective packaging inserts to B2C goods like laptop sleeves, placemats, and intricate signage. The laser's precision allows for the creation of sophisticated products that are lightweight, durable, and have a premium, modern aesthetic.

Felt's versatility, when combined with a laser, opens up a wide range of profitable markets.

1. Architectural and Interior Design

Felt is an excellent sound-absorbing material. With a laser, large sheets of PET felt can be cut into intricate patterns for use as acoustic wall panels, ceiling baffles, and room dividers. The laser perfectly seals every edge, ensuring a clean, professional finish without any complex finishing work.

2. Premium Packaging and Product Inserts

A custom-cut felt insert adds a touch of luxury and protection to any product packaging. Companies use lasers to create precise, no-fray cutouts that cushion electronics, jewelry, or spirits. The soft touch of felt communicates quality far better than foam or cardboard.

3. Tech Accessories and Homewares

The consumer goods market is full of laser-cut felt products. Items like laptop sleeves, phone cases, coasters, and decorative placemats are popular because they are durable, stylish, and lightweight. The laser allows for easy customization with logos or complex patterns, making it perfect for promotional goods.

What Are the Advantages of Laser Engraving on Felt?

Your current method for processing felt involves die-cutting or manual knife cutting. Die-cutting requires expensive custom tools with long lead times, and knife cutting is slow and imprecise. In both cases, the cut edges fray, requiring an extra finishing step like sewing or gluing, which adds significant labor cost and time to your process.

The single greatest advantage of using a laser on synthetic felt is that it cuts and finishes in one step. The laser's heat perfectly seals the material's edges as it cuts, creating a clean, no-fray finish that is impossible to achieve with mechanical methods. This eliminates entire steps from the production process, drastically increasing efficiency and reducing labor costs while delivering a superior quality product.

For a manager like John, these benefits translate directly to a stronger bottom line.

1. The No-Fray Edge: The Ultimate Advantage

This cannot be overstated. Traditional cutting methods shear the fibers, leaving them loose and prone to fraying. The laser melts and fuses the fibers, creating a solid, permanent edge. This means no need for hemming or other finishing processes. This single benefit can cut production time in half for many felt products.

2. Zero Contact, Zero Tool Wear

A laser beam never touches the material, so there are no blades or dies to wear down and replace. This means perfect consistency from the first piece to the ten-thousandth. It also eliminates the cost of tool replacement and the downtime associated with changing and recalibrating mechanical cutters.

3. Unmatched Design Freedom

A die-cutter is locked into one pattern. A laser can cut any design you can create in a software program. This allows for rapid prototyping, easy customization, and the creation of incredibly intricate patterns with sharp internal corners that are physically impossible for a die to produce.

What Other Applications Can Lasers Do on Felt?

You're now sold on the idea of laser cutting felt, but you're only thinking in two dimensions. You see it as a way to cut flat shapes, but you're not considering how the laser's unique properties can be used for more advanced, multi-layered applications. This limits your creative and manufacturing potential.

Beyond simple cutting and marking, lasers can be used for advanced techniques on felt. This includes creating "living hinges" by cutting specific patterns, producing multi-layered 3D components through kiss-cutting, and creating composite materials by fusing felt to other textiles. The laser's precise depth control and thermal properties open the door to innovative product designs that go far beyond simple flat shapes.

Thinking beyond the basic cut can give you a significant market advantage.

1. Kiss-Cutting for Multi-Layer Assembly

Kiss-cutting is a technique where the laser is set to a power level that only cuts through the top layer of a material. You can use this to cut intricate patterns on one layer of felt that is temporarily adhered to another. This is perfect for creating complex, multi-color logos or layered acoustic panels with incredible precision and no sewing required.

2. Living Hinges and Flexible Structures

While more common with wood, a laser can cut a carefully designed pattern of slits into a sheet of felt, allowing the normally rigid material to bend and fold like a hinge. This technique is perfect for creating unique foldable cases, book covers, or other three-dimensional objects from a single flat piece of felt.

3. Composite Material Creation

The thermal properties of a laser1 can be used to fuse synthetic felt to other laser-compatible fabrics. By layering felt with another textile and applying a defocused laser beam, you can effectively "weld" the materials together in specific patterns, creating custom composite textiles2 for unique applications in fashion or industrial design.

Conclusion

The true magic of laser engraving on felt isn't just in the beautiful designs it creates; it's in understanding the underlying science. By recognizing that we are melting synthetic fibers, not engraving natural ones, we unlock the process's real industrial power. The single greatest advantage is the laser's ability to create a perfectly sealed, no-fray edge, which combines cutting and finishing into one hyper-efficient step. This shift in perspective transforms felt from a simple craft material into a modern, high-value component for everything from architecture to luxury goods, driven by a process that delivers unmatched precision, speed, and quality.

Of course, August. Here are 10 highly relevant FAQs and a concise meta description based on the article's core insights. These are designed to directly answer the questions a professional like John would have, reinforcing your expertise in materials science, not just machinery.

FAQs

Q1: Why did my 100% wool felt get a burnt, smelly mark from the laser?

A: Natural wool felt is a protein fiber (like hair) that doesn't melt; it simply burns and chars. The process of "laser engraving" felt only works on synthetic materials like PET, which melt and fuse under the laser's heat to create a clean, debossed mark.

Q2: What is the single biggest advantage of using a laser on synthetic felt?

A: The no-fray edge. As the laser cuts synthetic felt, its heat melts and seals the fibers, creating a perfect, clean edge that will never fray. This combines the cutting and finishing processes into one step, drastically increasing production efficiency.

Q3: Is "laser engraving" felt the correct term?

A: Not technically. From a materials science perspective, you are not "engraving" (ablating material). You are performing a thermal fusion, melting the plastic fibers together. However, "laser engraving" has become the popular term in the market to describe the resulting debossed mark.

Q4: Do I need a high-power laser for felt?

A: Not necessarily. Since the process is about controlled melting, not vaporizing, a lower to mid-range power CO₂ laser (30W-60W) often provides more control and delivers a cleaner result. Too much power can easily burn through the material rather than just marking its surface.

Q5: What is PET felt, and why is it ideal for lasers?

A: PET felt is a non-woven textile made from recycled plastic bottles (Polyethylene terephthalate). It is ideal for lasers because it has a predictable melting point, allowing it to fuse cleanly for both cutting and marking, resulting in a sealed edge and a smooth finish.

Q6: Can I cut multiple layers of felt at once with a laser?

A: Yes, but with caution. While a laser can cut through several layers, the quality of the edge on the bottom layers may be slightly lower due to the defocused beam. For perfect consistency, it is often better to cut layers individually. For some applications, the slight welding of layers can be a desired effect.

Q7: How does die-cutting compare to laser cutting for felt?

A: Die-cutting requires a custom-made metal die, making it expensive for short runs and impossible for prototyping. It also produces a frayed edge that requires finishing. Laser cutting has zero tooling costs, allows for infinite design complexity, and produces a perfectly sealed, no-fray edge every time.

Q8: What is "kiss-cutting" on felt?

A: Kiss-cutting is a technique where the laser is set to a precise, low power to cut through only the top layer of a multi-layered material. It's used to create intricate, multi-color designs by cutting a shape from one color of felt and applying it to a backing layer without cutting all the way through.

Q9: Besides the smell, are there other downsides to laser cutting natural wool felt?

A: Yes, the primary downside is the poor quality. The cut edge will be charred, brittle, and inconsistent. The mark itself will be a sooty deposit rather than a clean, fused mark. It simply does not produce a commercially viable product.

Q10: What applications is laser-cut felt best for?

A: It excels in applications where a clean, no-fray edge is critical. This includes architectural acoustic panels, premium packaging inserts, tech accessories like laptop sleeves, coasters, and any design that requires intricate internal cuts that would be impossible with traditional methods.