As a purchasing manager, you see a fume extractor on the quote and likely think of it as a sunk cost—an expensive box you have to buy to meet OSHA requirements. It doesn't seem to add any real value to your production. You might even be tempted to find a cheaper alternative or just vent the fumes outside, assuming its only job is to handle a bit of smoke. But this common view overlooks a costly and hidden threat to your entire operation.

The main purpose of a fume extractor is to protect both the machine operator and the laser equipment itself. It is an active air purification system that captures and filters harmful airborne particles and corrosive fumes at the source. This dual function prevents serious health risks for staff while also stopping a damaging film of residue from building up on sensitive laser optics, which ensures the machine's long-term performance, precision, and uptime.

In my five years at Redshift Laser, I've had many conversations with purchasing managers like my client, John. He's excellent at what he does—sourcing high-quality machinery at the best price. Initially, he viewed fume extractors as a compliance accessory. But from the factory floor, we see them as a critical performance asset. The common misconception is that their sole purpose is protecting operators. In reality, they are equally vital for protecting the laser system. The particulates and corrosive fumes from materials like acrylic or PVC don't just vanish. They build up an invisible film on sensitive lenses and mirrors, degrading the laser's focus and power. This leads directly to higher scrap rates and premature, costly component failure. Let's break down why this machine is not just about safety, but about operational uptime and quality assurance.

What Are the Real Safety Challenges in Laser Cutting?

You know that laser cutting creates smoke, but you might assume a simple ventilation fan blowing outside is a good enough solution. It's easy to underestimate the specific, often invisible, dangers lurking within that plume of smoke and vapor. You might not realize that you're just moving a hazardous problem from inside your workshop to the area just outside, without actually solving it.

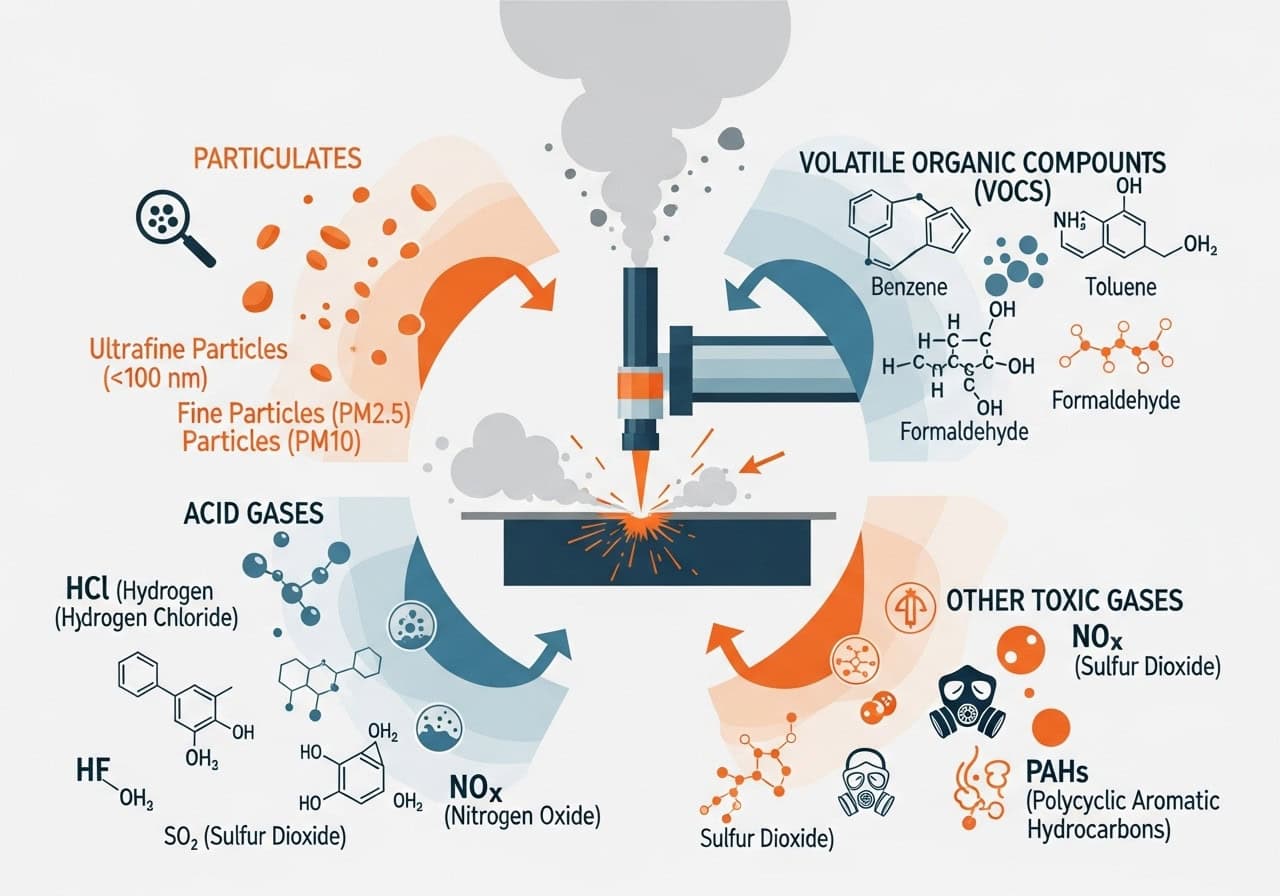

This isn't like campfire smoke. Depending on the material, laser fumes can contain a cocktail of toxic chemicals and ultrafine particles. Cutting PVC, for example, releases corrosive hydrochloric acid, while cutting acrylics can produce formaldehyde. These substances are not just irritants; they pose serious long-term health risks. A simple exhaust fan does nothing to neutralize these threats. A proper fume extractor is engineered to capture these specific hazards at the source and run them through a multi-stage filtration process, creating a genuinely safe and compliant workspace.

Protecting your team is always priority number one. The fumes generated by lasers aren't just unpleasant; they are a documented occupational hazard. Ensuring you have an effective air quality system in place isn't just about meeting regulations from bodies like OSHA; it's about providing a safe environment where your skilled operators can work without worrying about the air they breathe. A healthy team is a productive team, and investing in their safety leads to better morale and lower absenteeism.

Invisible Particulates and Health Risks

When a laser vaporizes material, it creates ultrafine particles (UFPs). These are so small that they can bypass the body's natural defenses and travel deep into the lungs, potentially entering the bloodstream. Long-term exposure to these particles is linked to respiratory and cardiovascular problems.

Corrosive and Toxic Gases

Many synthetic materials, especially plastics, release harmful gases when heated. PVC is notorious for releasing chlorine gas, which turns into hydrochloric acid when it meets moisture. This can cause severe damage to both the operator's respiratory system and the machine's internal components.

Compliance with Safety Regulations

Regulatory bodies like OSHA in the United States have strict rules regarding air quality in the workplace (Permissible Exposure Limits, or PELs). Failing to manage laser fumes properly can lead to heavy fines, legal issues, and a shutdown of operations. A certified fume extractor ensures you are always in compliance.

How Does a Modern Fume Extractor Actually Work?

You might think a fume extractor is just a box with a fan and a simple filter, similar to a shop vacuum. This perception makes it hard to justify the cost of a high-quality unit. You may wonder if the advanced features are really necessary or just marketing gimmicks designed to increase the price.

The truth is that a professional fume extractor is a sophisticated multi-stage air purification system, and its technology is crucial for dealing with complex laser fumes. The process starts with a pre-filter that captures large particles, extending the life of the more expensive filters that follow. Next, the air passes through a main HEPA filter, which is designed to trap up to 99.97% of those dangerous, microscopic particles. Finally, an activated carbon filter absorbs the toxic gases and odors. This multi-stage approach is the only way to effectively remove the full spectrum of hazards from the air.

I once visited a workshop that was using a cheap, single-stage extractor. The operator told me they had to replace the main filter every week, an enormous running cost. More importantly, he mentioned a persistent chemical smell. After we installed one of our Redshift units, he was amazed. The multi-stage system meant his main HEPA filter lasted for months, not days, and the activated carbon filter completely eliminated the odors. This is the difference technology makes—it's not just more effective, it's also more cost-efficient in the long run.

Stage 1: The Pre-Filter

This is the first line of defense. The pre-filter is typically a pad or bag filter designed to catch the largest dust particles. By removing these larger particles first, it prevents the main HEPA filter from clogging prematurely, which drastically reduces your operational costs.

Stage 2: The HEPA Filter

HEPA stands for High-Efficiency Particulate Air. This is the heart of the particulate filtration. A true HEPA filter is certified to capture at least 99.97% of airborne particles down to 0.3 microns in size. This includes the most dangerous ultrafine particles that can damage human lungs.

Stage 3: The Activated Carbon Filter

This final stage deals with the chemical threat. Activated carbon has a highly porous surface that adsorbs gas molecules, effectively trapping volatile organic compounds (VOCs), toxic fumes, and unpleasant odors. The volume of carbon in this stage determines how long it can work before needing replacement.

How Does Fume Extraction Enhance Machine Safety and Performance?

Okay, so the extractor protects your operators. But how does that justify the investment from a production standpoint? You might still see it as a "safety tax" on the machine, not something that directly improves your output or quality. It's difficult to connect a clean air system to a better bottom line.

This is the most overlooked benefit of a high-quality fume extractor: it directly protects your laser. The same corrosive fumes and sticky particulates that harm people also wreak havoc on your machine's most sensitive and expensive components—the optics. A fine layer of residue on a focusing lens or mirror will cause the laser beam to defocus and lose power. This leads to inconsistent cuts, failed jobs, and increased scrap rates. Over time, the heat buildup from the dirty optics will permanently damage them, leading to costly replacements and significant machine downtime.

John, the purchasing manager I work with, learned this the hard way. His company bought a laser system and paired it with a cheap, underpowered extractor to save money. Within six months, they called for a service visit, complaining about a loss of cutting power. Our technician opened the machine and found the main lens was cloudy and pitted. The cost to replace it, combined with the two days of lost production, was more than the money they had saved on the cheap extractor. Effective fume extraction isn't an expense; it's insurance for your investment.

Protecting Your Optics

Lenses and mirrors are the most critical components for beam quality. A fume extractor removes the particulates and sticky aerosols before they can settle on these surfaces. Clean optics mean a perfectly focused beam, consistent power delivery, and high-quality results on every job.

Reducing Mechanical Wear

Debris and corrosive elements can also settle on the machine's moving parts, like guide rails and bearings. This buildup can accelerate wear and tear, leading to premature mechanical failures and costly repairs. A clean internal environment extends the life of the entire system.

Maximizing Uptime and ROI

By preventing component failure and ensuring consistent cut quality, a fume extractor directly contributes to your machine's uptime. Less downtime for cleaning, repairs, and re-running failed jobs means higher productivity and a faster return on your initial investment.

| Problem Without Extractor | Solution With Extractor | Financial Impact |

|---|---|---|

| Dirty Optics / Beam Scatter | Clean optics maintain focused beam | Higher cut quality, lower scrap rates |

| Premature Component Failure | Protects lenses, mirrors, and rails from damage | Reduced repair costs and replacement parts |

| Inconsistent Results | Delivers consistent power for repeatable jobs | Improved product quality and customer satisfaction |

| Unplanned Downtime | Minimizes failures caused by contamination | Increased productivity and operational efficiency |

What Features Should You Look for in a Fume Extractor?

You're convinced that a quality fume extractor is necessary, but how do you choose the right one? They all look like gray boxes, and the spec sheets are full of technical jargon. You need to know which features actually matter for a laser cutting application to make a smart purchasing decision.

The most important features to look for are the airflow rate (measured in CFM or m³/hr), a high-quality, multi-stage filtration system, and intelligent features like an automatic flow control and filter status monitoring. The airflow rate must be sufficient for the size of your laser's work area. Automatic flow control is a key feature—it adjusts the fan speed as the filter loads up with particles, maintaining consistent suction power over the life of the filter. This ensures your protection doesn't fade as the filter gets dirty.

When John was ready to invest in a proper system, we focused on these details. He needed an extractor for a large-format laser cutting acrylics. We selected a Redshift Pro unit with a high CFM rating to cover the entire bed and a deep activated carbon filter to handle the chemical load. The feature he appreciated most was the filter status indicator. It gave him a clear visual warning when the filters were nearing the end of their life, allowing him to order replacements in advance and schedule maintenance without any unexpected downtime.

Sufficient Airflow (CFM)

The CFM (Cubic Feet per Minute) rating tells you how much air the unit can move. This must be matched to the size of your laser engraver. An underpowered unit will not be able to create enough negative pressure to capture all the fumes effectively.

Multi-Stage Filtration (HEPA & Carbon)

Do not compromise here. Ensure the unit has, at a minimum, a pre-filter, a primary HEPA filter, and a substantial activated carbon filter. For heavy-duty applications, look for deep-bed carbon filters, as they last longer and are more effective.

Intelligent System Controls

Modern extractors include features that make them easier and safer to operate. Automatic flow control1 maintains constant suction, while alarms for blocked or full filters2 remove the guesswork from maintenance. These features ensure the unit is always performing at its best.

Conclusion

A fume extractor is far more than a simple safety accessory or a regulatory burden. It is an essential component of a high-performance laser system. While its primary role is to protect the health of your operators by removing hazardous fumes, its secondary function is just as critical: protecting the health of your machine. By preventing the buildup of damaging residue on optics and mechanical parts, a quality fume extractor directly enhances cut quality, minimizes scrap rates, and reduces costly downtime. When you view it not as a cost, but as an investment in uptime and quality assurance, its true value becomes clear.