You're looking to expand into laser-cutting plastics, attracted by the endless creative possibilities. But you're worried about the stories you've heard—of melted edges, toxic smoke, and inconsistent results. You feel overwhelmed by the sheer number of different plastics, and you fear that choosing the wrong one could be a costly mistake, not just in wasted material, but in damage to your expensive machine and risk to your team.

The most suitable plastics for a CO2 laser are those that are chemically stable during thermal decomposition. The key is choosing polymers that vaporize cleanly, like acrylic (PMMA), without releasing highly toxic or corrosive gases. Materials like PVC, ABS, and vinyl must be avoided entirely. Their unsuitability isn't about a poor cut finish; it's a critical safety issue, as they release gases that are hazardous to operators and actively corrode the laser cutter's internal components.

I'll never forget the call I got from a workshop owner in distress. He had bought a new laser cutter and, excited to start, began cutting logos out of a flexible plastic sheet a client gave him. A week later, his machine started faulting. When our technician arrived, he found the lens coating was fogged, the mirror surfaces were pitted, and the metal guide rails showed early signs of rust. The "flexible plastic" was PVC. The hydrochloric acid released during cutting had created an acid bath inside his machine, causing thousands of dollars in damage. That day, the cost of the material was measured by the price of a new motion system.

What is the function of a CO2 laser cutting machine?

You see a laser cutter as a simple tool for cutting shapes, a sort of automated craft knife. You assume it works the same way on every material. But when it comes to plastics, you're puzzled why it cleanly slices through one type but creates a gooey mess with another. You need to understand the fundamental process to make smart material choices.

A CO2 laser cutting machine functions by generating an intense, focused beam of infrared light that is absorbed by the plastic. This absorption causes the material to heat up instantly and vaporize, creating a cut with a very small heat-affected zone. Unlike a blade, the laser cuts without physical contact, enabling intricate designs without putting mechanical stress on the material. It's not a cutting tool; it's a controlled vaporization system.

The "magic" of a CO2 laser lies in its specific wavelength and how it interacts with materials.

The Right Wavelength for Organics

A CO2 laser emits light in the far-infrared spectrum, at a wavelength of 10.6 micrometers. This specific wavelength is very poorly absorbed by metals but is highly absorbed by organic materials, which includes all plastics, as well as wood, paper, and leather. This is why a CO2 laser is the perfect tool for these materials.

From Light to Vapor

When the focused laser beam hits the plastic, the energy is absorbed so rapidly that the material doesn't have time to conduct the heat away. It instantly heats the polymer chains past their boiling point, causing them to vaporize. A jet of compressed air, known as an air assist, blows this vapor away, leaving a clean cut path.

Mechanical vs. Laser Cutting

| Feature | Mechanical Cutting (Blade/Router) | CO2 Laser Cutting |

|---|---|---|

| Contact | Direct physical contact | No-contact process |

| Material Stress | High (can cause cracking/chipping) | Very low (no mechanical stress) |

| Edge Finish | Often rough, requires secondary finishing | Can be flame-polished (on acrylic) |

| Design Complexity | Limited by tool size and shape | Nearly unlimited, perfect for intricate details |

Why is there variability in behavior among different plastics?

You've tried cutting two different types of plastic that look almost identical. One cuts with a perfect, glossy edge, while the other turns into a charred, melted disaster. This inconsistency is frustrating and expensive, making you feel like you're gambling with every new sheet of material. You need to know why this happens to predict the outcome before you press "start."

The variability in how plastics react to a laser is due to their fundamental chemical structure. Plastics are divided into two main families: thermoplastics and thermosets. Thermoplastics, like acrylic, melt when heated and tend to produce a clean, polished edge. Thermosets, on the other hand, are cross-linked polymers that do not melt; they simply char and decompose when heated, resulting in a poor-quality cut.

Understanding the two families of plastics is the first step in successful laser cutting.

Thermoplastics: The Melters

Think of thermoplastics as chains of molecules tangled together like spaghetti. When you apply heat, these chains can slide past each other, causing the material to soften and melt. This is why materials like acrylic (PMMA) work so well. The laser melts the edge as it vaporizes the material path, creating a beautiful "flame-polished" finish. Examples include Acrylic (PMMA), PETG, and Polystyrene.

Thermosets: The Burners

Thermosets have a different structure. Their polymer chains are cross-linked, connected by strong chemical bonds that form a rigid, 3D network. They are like a net, not spaghetti. When you apply heat, these bonds prevent the chains from melting or sliding. Instead, the polymer simply burns and decomposes, or "chars." This results in a rough, sooty edge. Examples include Polyurethane, Silicone, and Epoxy resins.

The Hidden Danger: The Thermal Decomposition Pathway

This is the most critical concept. When a plastic vaporizes, what does it turn into? This is its thermal decomposition pathway.

- Safe Pathway: Acrylic vaporizes back into its original monomer components, which can be managed with standard ventilation.

- Dangerous Pathway: PVC (polyvinyl chloride) has chlorine atoms in its structure. When vaporized, it releases chlorine gas. This gas immediately combines with moisture in the air to form hydrochloric acid—a highly corrosive acid that destroys machine components and is incredibly toxic to breathe.

What are the most suitable types of plastics for a CO2 Laser Cutting machine?

Now that you're aware of the hidden dangers, you're hesitant to cut any plastic at all. You need a straightforward "safe list"—a clear guide to which materials will give you a great result without creating a toxic environment or silently destroying your machine from the inside out. You need confidence in your material choices.

The most suitable plastics are those that vaporize cleanly into manageable fumes. Acrylic (PMMA) is the gold standard, offering a beautiful flame-polished edge and predictable results. Following that, plastics like PETG and Delrin (POM) are also excellent candidates, though they require very good ventilation. The common thread is that they do not release corrosive acids or cyanide-based compounds, making them safe for both the operator and the machine.

This isn't about preference; it's about safety and asset protection.

The "Green Light" List (Safe to Cut with Good Ventilation)

- Acrylic (PMMA, Plexiglas, Lucite): The best all-around plastic for laser cutting. It cuts cleanly, engraves beautifully, and produces a stunning flame-polished edge.

- Delrin (POM): An engineering plastic that cuts very cleanly, leaving a smooth, matte finish. It is excellent for gears and mechanical parts. Requires strong ventilation.

- PETG: Often used in packaging. It doesn't polish like acrylic and can sometimes have a slightly sticky edge, but it cuts safely without producing highly toxic fumes.

The "Red Light" List (NEVER Cut with a CO2 Laser)

This is the list that protects your investment and your people. The "unsuitability" of these materials is not about cut quality; it's a chemical liability.

| Plastic | Gaseous Byproducts | Impact on Machine & Operator |

|---|---|---|

| PVC (Vinyl, Sintra) | Chlorine Gas (Hydrochloric Acid) | EXTREME DANGER: Corrodes optics, bearings, rails. Highly toxic. |

| ABS | Cyanide Gas, Butadiene | EXTREME DANGER: Releases potent poisons. |

| Polycarbonate (Lexan) | Carbon Monoxide, soot | High fire risk, absorbs IR poorly, leaves a charred, useless edge. |

| Fiberglass / Carbon Fiber | Epoxy resin fumes, glass/carbon dust | EXTREME DANGER: Fumes are toxic. Dust is a severe respiratory hazard. |

How to choose a suitable laser cutting machine for plastics?

You're ready to invest, but you want to ensure the machine you buy is built for the job. You're concerned that a generic machine won't have the specific features needed to handle plastic cutting safely and effectively. You need to know what to look for on a spec sheet beyond just bed size and power.

When choosing a laser cutter for plastics, prioritize safety and control features over raw power. The most critical component is a high-volume, professional-grade fume extraction system. Additionally, look for a machine with high-quality, coated optics that can better withstand chemical exposure, and ensure the software allows for fine-tuned control over the laser's power settings to manage heat input effectively.

As a purchasing manager, think of this purchase as risk mitigation.

1. Fume Extraction is Not Optional

This is your number one priority. A simple exhaust fan vented out a window is not enough. You need a system with enough airflow (measured in CFM or m³/hr) to create negative pressure inside the machine, ensuring no fumes escape into the workshop. For a professional environment, a filtered extraction system that captures volatile organic compounds (VOCs) is the responsible choice.

2. Inspect the "Guts" of the Machine

Look at the components that will be exposed to the fumes.

- Optics: Are the mirrors and lens made by a reputable brand1? Do they have durable coatings2? These are the first things to be destroyed by corrosive gas.

- Motion System: Are the guide rails made of stainless steel3 or properly coated? These can be quickly ruined by the acidic residue4 from cutting the wrong material.

3. Choose a Supplier Who is a Safety Partner

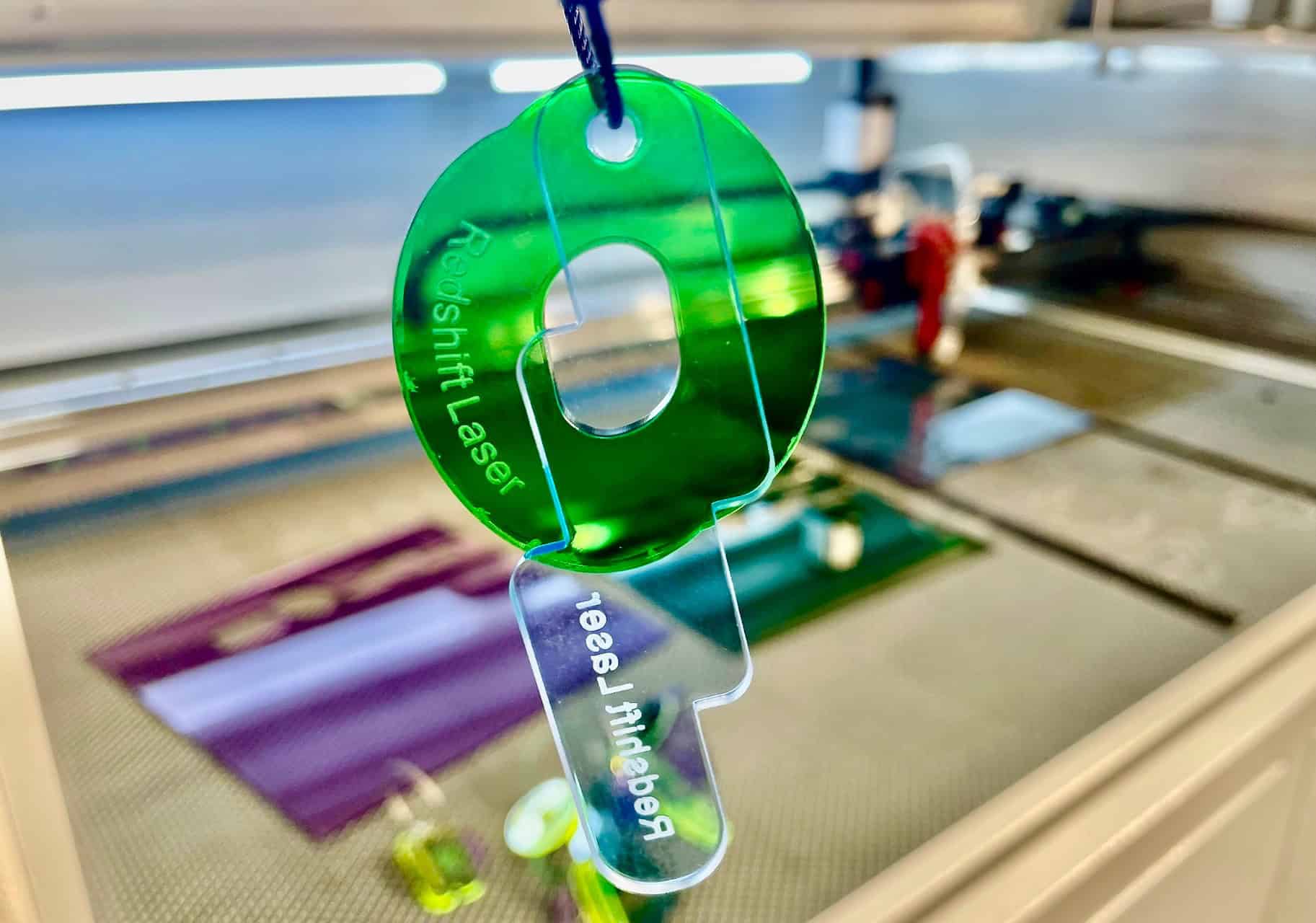

Your supplier should be a source of expertise. Ask them directly: "Which materials are dangerous to cut on this machine and why?" A good supplier will give you a clear, honest answer that aligns with the "Red Light" list above. A great supplier, like we aim to be at Redshift Laser, will refuse to even do a test cut on PVC5. Their caution is a sign of their expertise.

Conclusion

Choosing the right plastic for your CO2 laser cutter is ultimately not a creative decision, but a technical and financial one. While the aesthetic of a flame-polished edge on acrylic is a great benefit, the real win is avoiding the catastrophic operational liability of using the wrong material. By understanding that material selection is an act of asset protection—safeguarding your machine's expensive components and your operators' health—you move beyond the simple discussion of cut quality. You are making a strategic decision that protects your investment, your people, and your bottom line for years to come.

FAQs

Q1: Why can't I just cut any plastic with my CO2 laser?

A: Because different plastics have different chemical compositions. Some, like PVC and ABS, release highly toxic and corrosive gases (hydrochloric acid and cyanide) when vaporized. These gases are a severe health hazard to operators and will actively destroy your machine's expensive optics, bearings, and metal components.

Q2: What is the single most dangerous plastic to laser cut?

A: Polyvinyl Chloride (PVC), also known as vinyl. It releases chlorine gas which instantly forms hydrochloric acid in the air. This is not a "bad cut" issue; it is a catastrophic failure event for your machine and a serious health risk.

Q3: Is acrylic (Plexiglas) really safe to laser cut?

A: Yes, with proper ventilation. Acrylic (PMMA) is the ideal plastic for CO2 lasers. It vaporizes cleanly into its original monomer components, which are manageable with a good fume extraction system. It also produces a beautiful, flame-polished edge quality.

Q4: My laser has a simple exhaust fan. Is that enough for cutting safe plastics like acrylic?

A: For a professional workshop, a simple fan is not adequate. You need a professional-grade fume extraction system that creates negative pressure within the machine and effectively vents all fumes outside. For indoor operation, a filtered system that captures and neutralizes volatile organic compounds (VOCs) is the responsible choice.

Q5: What are the signs that I've accidentally cut the wrong plastic?

A: Immediate signs include unusually thick, acrid, or colored smoke and a very poor, sooty cut quality. Over time, the signs are machine-related: fogged or pitted lenses and mirrors, premature rust on guide rails and bearings, and unexplained electronic faults.

Q6: What does "thermoplastic" vs. "thermoset" mean for laser cutting?

A: Thermoplastics (like acrylic) melt and soften when heated, which allows them to be cut cleanly with a polished edge. Thermosets (like epoxy or polyurethane) are chemically cross-linked and do not melt; they simply char and decompose when heated, resulting in a very poor, unusable cut edge.

Q7: Can I laser cut polycarbonate (Lexan)?

A: You should not. While not as corrosive as PVC, polycarbonate absorbs the CO2 laser's infrared energy very poorly and tends to melt and burn rather than vaporize cleanly. It produces a discolored, sooty edge, catches fire easily, and releases toxic fumes.

Q8: What is Delrin (POM) and is it good for laser cutting?

A: Delrin (POM) is a high-performance engineering thermoplastic. It is excellent for laser cutting, producing a very clean, smooth, and precise edge with a matte finish. It is often used for making gears, jigs, and mechanical parts. It requires very good ventilation due to strong-smelling fumes but is safe for the machine.

Q9: Besides the plastic type, what else affects the cut quality?

A: The three key parameters are laser power, cutting speed, and the effectiveness of your air assist. You must balance power and speed to ensure the material is vaporized cleanly without applying excess heat. A strong air assist is crucial for blowing away vapor and preventing melting or flaming.

Q10: When buying a laser for plastics, what's a key feature to look for?

A: Prioritize the quality of the fume extraction system offered with the machine. Second, look for a supplier who understands the chemical dangers and can act as a safety partner. Their knowledge of what not to cut is as valuable as the machine itself.

Relate

-

Exploring this link will help you identify trusted brands that ensure quality and durability in optics. ↩

-

Understanding durable coatings can enhance your knowledge of how to protect your optics from damage. ↩

-

Explore this link to understand why stainless steel is crucial for durability and performance in motion systems. ↩

-

Learn about the impact of acidic residue on materials to ensure the longevity of your motion systems. ↩

-

Exploring this topic can help you understand the risks associated with cutting PVC and enhance your safety protocols. ↩