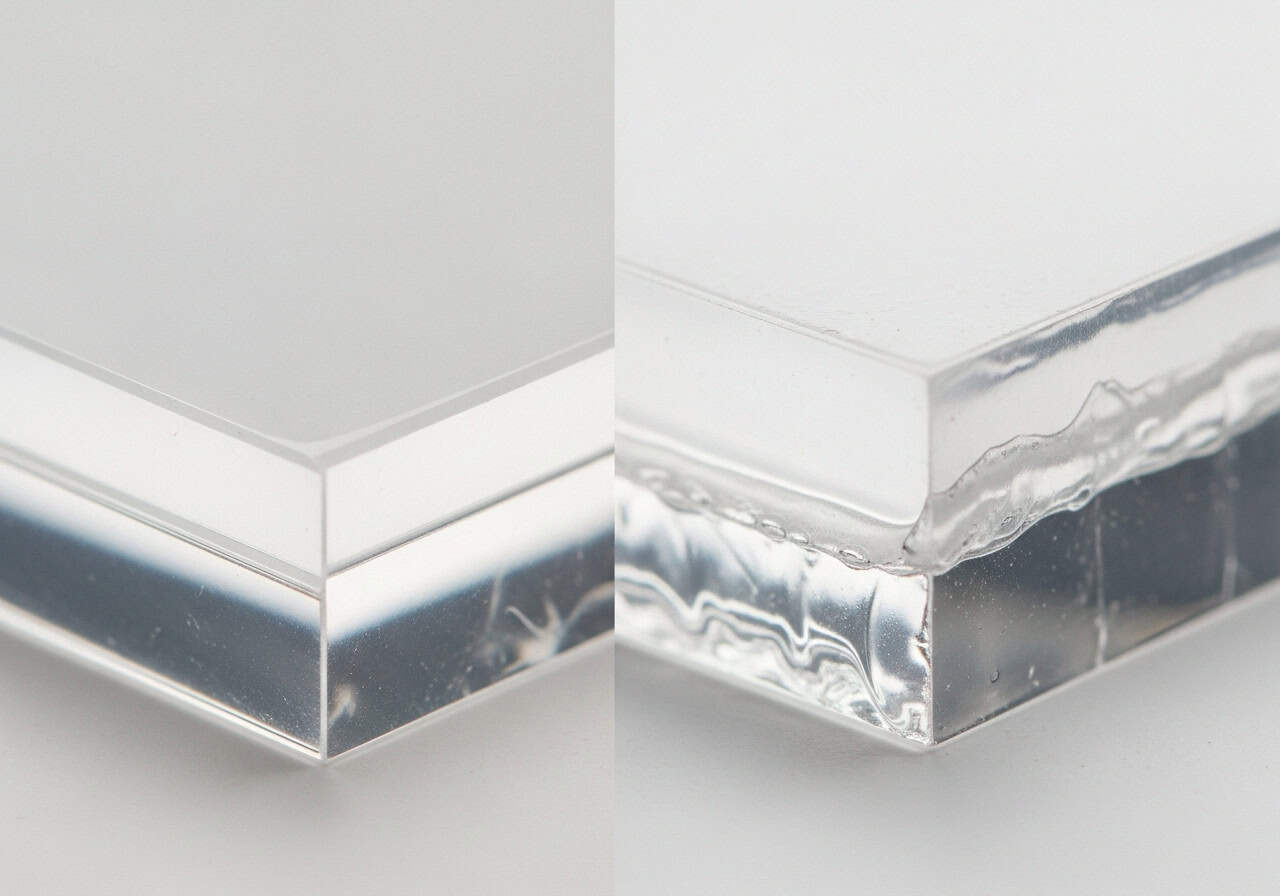

You are tasked with producing high-quality acrylic parts, but your results are maddeningly inconsistent. One day the edges are perfect—glossy and smooth—and the next they're raised, gummy, and look unprofessional. You find yourself constantly tweaking settings, wasting expensive material, and falling behind schedule. This inconsistency is making you question your machine, your process, and whether you can deliver the quality your clients demand.

The most important trick for laser cutting acrylic is choosing the right type of material: cast acrylic is vastly superior to extruded acrylic. Cast acrylic is stress-free and vaporizes cleanly, producing a signature flame-polished edge. Extruded acrylic contains internal stresses that cause it to melt back, creating a raised, inferior edge. Mastering this material choice is far more critical than any minor adjustment to your machine's speed or power settings for achieving a perfect, saleable product every time.

I'll never forget a client—a talented display designer—who called me in frustration, convinced we had sold him a faulty laser machine. He showed me two acrylic parts cut from the same file with the exact same settings. One was flawless, with a glass-like edge. The other had a raised, gummy lip that looked terrible. After a few questions, we found the cause. To save a few cents per square foot, his purchasing department had switched suppliers, and he was now using extruded acrylic instead of the cast acrylic he'd used before. That tiny "cost saving" was about to ruin a high-value project. This experience cemented my core belief: your material is your most important setting.

What are the Advantages of Laser Cutting Acrylic Sheets?

You're currently using traditional tools like routers or saws to cut acrylic. You're dealing with the loud noise, the plastic dust getting everywhere, and the constant risk of chipping delicate parts. Worse, every single piece requires a time-consuming secondary finishing process of sanding, buffing, and flame polishing to get an acceptable edge. This multi-step workflow is slow, labor-intensive, and a bottleneck in your production.

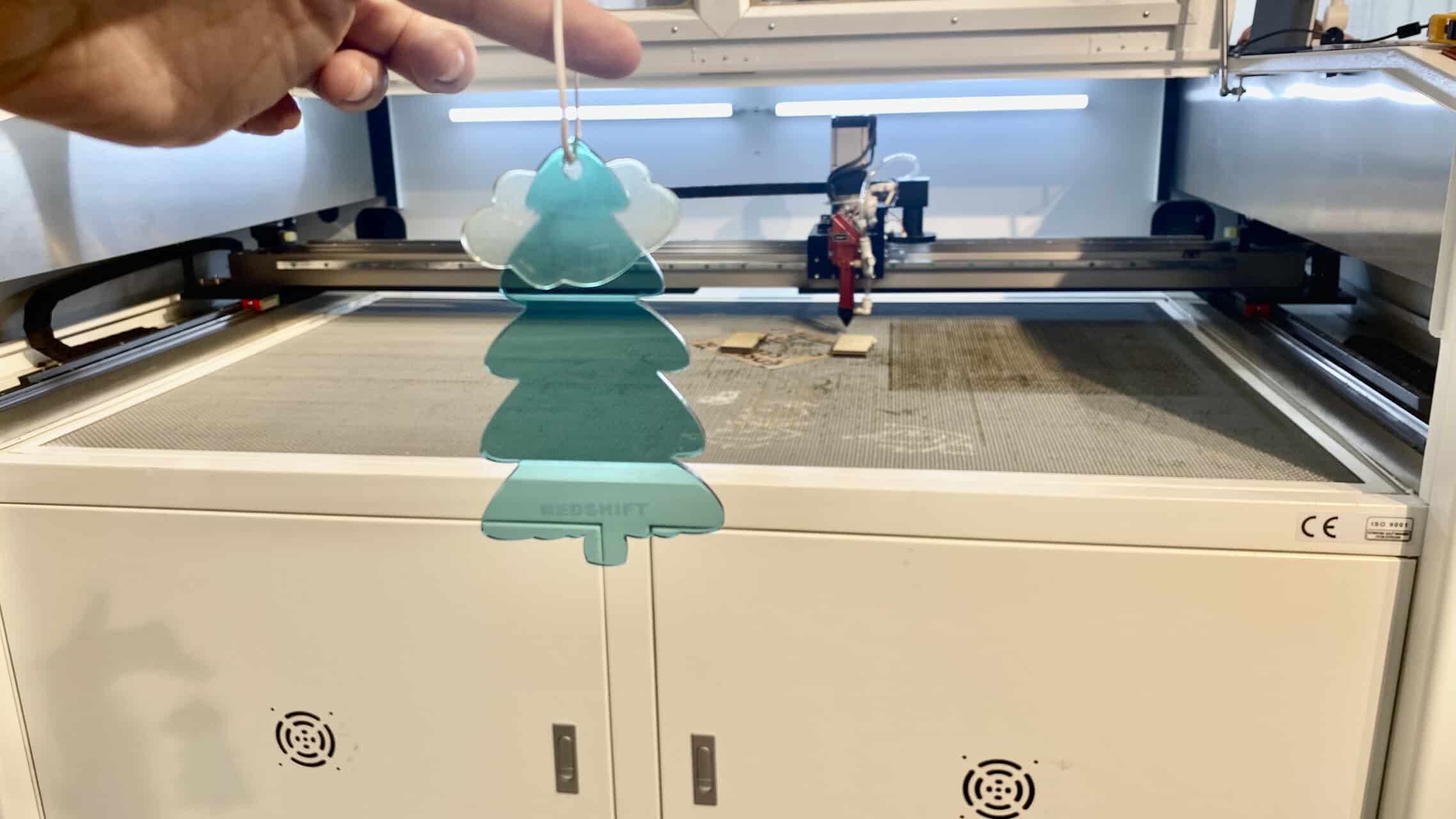

The primary advantage of laser cutting acrylic is achieving a perfectly flame-polished edge directly in the cutting process, eliminating the need for secondary finishing. This single-step method saves enormous amounts of time and labor. Other key advantages include the ability to cut extremely intricate designs without mechanical stress, which prevents chipping, and the unmatched speed and precision for producing identical parts in a production run.

The laser's benefits go far beyond just a pretty edge; they represent a fundamental improvement in manufacturing efficiency.

One-Step Cutting and Polishing

When a CO2 laser cuts acrylic, it's not actually a "cut" in the mechanical sense. The intense, focused beam of light vaporizes the material in its path. As it does so, the heat melts the surrounding edge just enough to create a smooth, glossy, flame-polished finish. This happens instantly, combining two or three separate manufacturing steps into one.

No Mechanical Stress

A router bit or saw blade puts immense physical force on the acrylic sheet. This is especially problematic on sharp corners or thin sections, where it can easily cause chipping, micro-fractures, or a complete break. The laser is a no-contact tool. Nothing touches the acrylic but a beam of light, meaning even the most fragile and intricate designs can be cut without any risk of mechanical stress.

Tool Wear and Maintenance

Mechanical cutting tools like router bits and saw blades wear down. As they get dull, the cut quality degrades, and they need to be replaced, adding to operational costs and downtime. A laser has no physical cutting edge to wear out. The optics require regular cleaning, but their operational life is vastly longer than that of a mechanical bit.

| Feature | Laser Cutting | Mechanical Cutting (CNC Router) |

|---|---|---|

| Edge Finish | Flame-polished, straight off the machine | Rough, requires secondary finishing |

| Process Steps | One single step (cut & polish) | Multiple steps (cut, sand, buff, polish) |

| Material Stress | None (no-contact process) | High (can cause chipping/cracking) |

| Intricacy | Very high (cuts sharp, internal corners) | Limited by tool diameter |

What Types of Acrylic Sheets are Suitable for Laser Cutting?

You know "acrylic" is the right material, but you see different types listed by your supplier, like "cast" and "extruded." To you, they look and feel almost identical, but the extruded version is always cheaper. You assume it's the smarter financial choice. This assumption, however, is the root cause of your inconsistent results and production headaches, turning a small material saving into a major operational cost.

The two main types of acrylic sheets are cast and extruded, and their suitability for laser cutting is vastly different. Cast acrylic is the ideal choice. It is made by pouring liquid monomer into a glass mold, resulting in a stress-free material that vaporizes cleanly for a perfect, flame-polished edge. Extruded acrylic is formed by pushing acrylic mass through a die, which induces internal stress, causing it to melt back and create a raised, gummy edge when laser cut.

From a procurement perspective, extruded acrylic's lower price is attractive. From a manufacturing perspective, it's a false economy.

Cast Acrylic (The Professional's Choice)

Cast acrylic is made like casting a cake in a pan. Liquid acrylic is poured between two sheets of glass and cured in a slow, controlled process. This creates a sheet with very little internal stress. When the laser's heat hits it, the material vaporizes cleanly without any molecular "memory" pulling it in different directions. The result is a crisp, clean, burr-free edge with that signature glossy finish.

Extruded Acrylic (The Hidden Liability)

Extruded acrylic is made like squeezing toothpaste from a tube. A hot mass of acrylic is pushed through rollers and dies to form a sheet. This process forces the polymer chains to align in the direction of extrusion, locking in a huge amount of internal stress. When the laser's focused heat hits this stressed material, the molecular chains relax and pull back from the cut line, causing the material to melt back and form a raised, gummy lip on the edge.

Why This Matters on the Factory Floor

This isn't just a minor quality difference.

- Post-Processing: Edges cut on extruded acrylic often require scraping or sanding to remove the burr, completely defeating the main advantage of laser cutting.

- Operational Parameters: You need different settings to cut extruded acrylic, often requiring a more complex setup to minimize the melting effect.

- Saleable Product: For high-end applications like signage or displays, the edge finish from extruded acrylic1 is often unacceptable to the end customer.

How do you Choose the Right Laser Cutting Machine for Acrylic Sheets?

You're ready to invest in a machine specifically for cutting acrylic. You see a huge range of options, from small desktop units to large industrial machines, all with different power ratings and features. You're worried about overspending on a machine with more power than you need, or underspending and getting a machine that can't deliver the quality and throughput your business requires.

Choosing the right laser for acrylic depends on the thickness of the material you plan to cut. Power is key: a 40-60W machine is perfect for sheets up to 1/4" (6mm), an 80-100W machine is ideal for thicknesses up to 1/2" (12mm), and a 130-150W machine is required for efficiently cutting 1" (25mm) acrylic. Equally important are a high-quality Z-axis for precise focusing and a good air-assist to prevent flaming and ensure a clean cut.

It's not about buying the most powerful machine; it's about buying the right machine for your specific job.

Power Correlates to Thickness

The laser's power (in watts) determines how thick of a material it can cut cleanly and efficiently. Trying to cut thick acrylic with an underpowered laser will result in a tapered, angled edge or will simply fail to cut through. Using an overpowered laser on very thin material can be overkill and make fine-tuning the settings more difficult.

| Material Thickness | Recommended Laser Power (CO2) | Primary Application |

|---|---|---|

| Up to 1/4" (6mm) | 40W - 60W | Signage, jewelry, intricate crafts |

| Up to 1/2" (12mm) | 80W - 100W | Display stands, moderate fabrication |

| Up to 1" (25mm) | 130W - 150W+ | Block letters, structural parts |

The Importance of Focus (Z-Axis)

The laser beam must be perfectly focused on or slightly into the surface of the acrylic to achieve a clean cut. A machine with a high-quality, motorized Z-axis2 allows you to set this focal point with precision. An auto-focus feature3 is a huge time-saver in a production environment, ensuring consistent results from one sheet to the next.

Don't Forget Air Assist

A good air-assist system4 is non-negotiable. It directs a focused stream of compressed air5 at the cutting point. This does two critical things: it instantly extinguishes the small flame that can occur when vaporized acrylic ignites, and it blows the molten material down and away from the cut, preventing it from re-solidifying on the top edge. This is essential for maintaining that clean, polished finish.

Conclusion

Mastering the art of laser cutting acrylic is less about memorizing a thousand different machine settings and more about one fundamental choice: always use cast acrylic. While the lower price of extruded acrylic may seem tempting from a procurement standpoint, it is a false economy that leads to inferior quality, increased labor costs for post-processing, and production inconsistencies. By starting with the right, stress-free material, you set yourself up for success. Pairing cast acrylic with the correctly powered machine and proper focus ensures you can consistently and efficiently produce the beautiful, flame-polished parts that your clients expect, straight off the laser bed.

FAQs

Q1: Why are the edges of my laser-cut acrylic gummy or raised instead of smooth?

A: This is the classic sign of using extruded acrylic instead of cast acrylic. Extruded sheets contain internal stresses from their manufacturing process, which causes the material to melt back and form a raised lip when cut with a laser. Cast acrylic is stress-free and vaporizes cleanly.

Q2: What is the main difference between cast and extruded acrylic for laser cutting?

A: The manufacturing process. Cast acrylic is made by pouring liquid into a mold, resulting in a stress-free sheet that produces a flame-polished edge. Extruded acrylic is pushed through a die, creating internal stress that results in an inferior, melted edge when laser cut.

Q3: Is cast acrylic more expensive, and is it worth the extra cost?

A: Yes, cast acrylic typically has a higher upfront material cost. However, it is absolutely worth it. It saves significant time and money by eliminating the need for secondary post-processing (like sanding or scraping edges), leading to a lower total cost of ownership and a superior final product.

Q4: What laser power (watts) do I need for cutting acrylic?

A: This depends on the thickness. As a general guide: use 40-60W for acrylic up to 1/4" (6mm), 80-100W for material up to 1/2" (12mm), and 130W+ for sheets up to 1" (25mm) to achieve a clean, efficient cut.

Q5: How can I prevent flames or flare-ups when laser cutting acrylic?

A: Use a strong and properly directed air assist. The compressed air stream extinguishes the small flame created by the vaporizing acrylic and, just as importantly, blows molten material down and away from the cut, ensuring a clean top edge.

Q6: Is cast or extruded acrylic better for laser engraving?

A: Cast acrylic is vastly superior for engraving. It produces a crisp, frosty white finish that provides excellent contrast. Extruded acrylic engraves clear and tends to look messy and less professional, with less contrast.

Q7: Where should I set the laser's focal point for cutting acrylic?

A: For the straightest possible edge on thicker materials, a good starting point is to set the focal point about one-third of the way down into the material's thickness. For thin acrylic, focusing on the top surface is usually sufficient.

Q8: Can I achieve a polished edge on extruded acrylic by changing my settings?

A: Not to the same quality as cast acrylic. While you can sometimes improve the result by using lower power and a faster speed to minimize heat input, you will not be able to replicate the true, glass-like flame-polished edge that cast acrylic naturally produces.

Q9: Why does my acrylic sometimes crack or chip near the cut line?

A: This is typically an issue with mechanical cutting tools like saws or routers, not lasers. One of the key advantages of laser cutting is that it is a no-contact process, which puts zero mechanical stress on the acrylic and eliminates the risk of chipping or stress fractures.

Q10: Besides the laser, what is the most important component for cutting acrylic?

A: A high-quality fume extraction system. Vaporizing acrylic releases fumes with a strong odor that must be vented safely outside or filtered. Proper extraction is critical for operator safety and maintaining a clean work environment.

Relate

-

Explore this link to understand how extruded acrylic enhances signage quality and customer satisfaction. ↩

-

Understanding the importance of a high-quality motorized Z-axis can enhance your laser cutting precision and efficiency. ↩

-

Exploring the benefits of an auto-focus feature can help you achieve consistent and efficient results in your laser cutting projects. ↩

-

Understanding air-assist systems can enhance your cutting techniques and improve the quality of your work. ↩

-

Exploring the role of compressed air can help you optimize your cutting efficiency and achieve better results. ↩