You're trying to source wood for a large-scale engraving project. You've followed the online guides, picking out "ideal" species like cherry or maple, but your results are a disaster. One piece engraves beautifully, while the next one is a scorched, inconsistent mess. The production line stops, costs are mounting, and everyone is looking at you, the person who sourced the "bad" material.

The secret to perfect wood engraving isn't the species of the tree, but the consistency of the timber. The "perfect" wood is one with minimal resin pockets, a uniform grain density, and consistent moisture content. These factors ensure the laser interacts predictably across the entire surface. True success at scale comes from sourcing predictable, stable lumber, because consistency—not a specific wood name—is what dictates profitability.

I’ll never forget a client who wanted to make 10,000 engraved gift boxes from a batch of beautiful, but notoriously resinous, pine. He loved the rustic look. I warned him, but he insisted. The first few tests looked great, but in full production, it was chaos. Hidden resin pockets would flare up, scorching the designs and, in one case, setting off our machine's fire alarm. We had to stop the job constantly to adjust settings. He learned a hard lesson that day: for a business, predictable and boring is always more profitable than beautiful and unpredictable.

Laser Engraving Wood: The Precision Revolution & Applications?

You're stuck with traditional methods like branding or CNC routing. Branding irons are imprecise and can't handle detailed logos. CNC routers are slow, create sawdust, and the tools wear down, leading to inconsistent depths and costly replacements. You feel limited by your tools, unable to deliver the fine detail your customers are demanding without sacrificing efficiency.

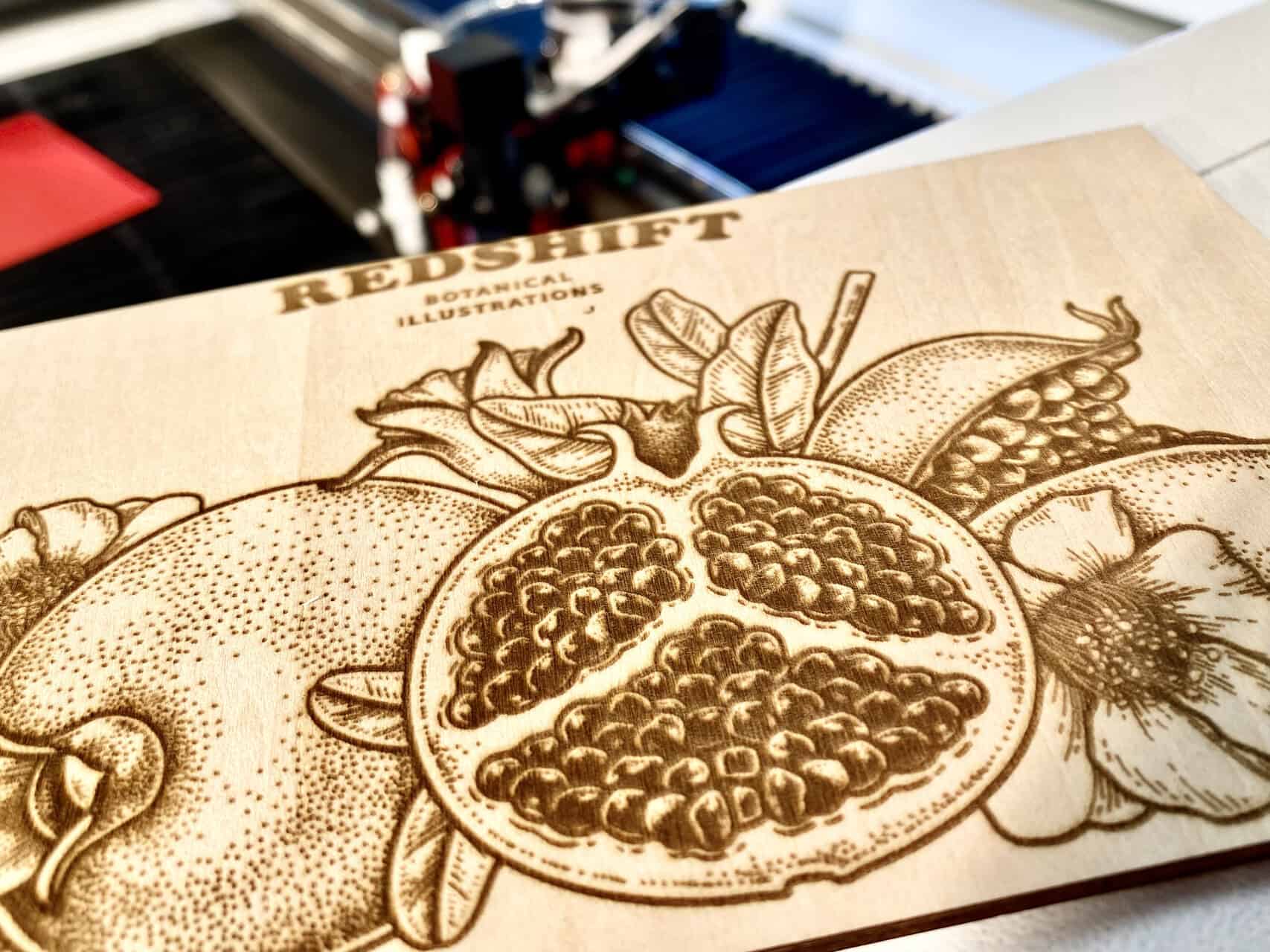

Laser engraving is a non-contact process that uses a focused beam of light to vaporize wood fibers with incredible precision, creating a permanent mark without any mechanical force. This allows for intricate designs, sharp text, and consistent results that are impossible with traditional methods. By turning a digital design directly into a physical engraving, it offers unmatched speed and versatility for a huge range of applications.

The laser offers a fundamental shift in how we mark wood. It's not about chipping material away; it's about turning it into smoke with surgical accuracy.

1. The Science of Vaporization

A CO₂ laser emits a beam of infrared light that is readily absorbed by wood. This intense energy instantly heats the wood fibers past their combustion point, vaporizing them in a tiny puff of smoke. By controlling the power and speed of the beam, you control the depth and darkness of the mark, creating a permanent, high-contrast engraving.

2. Common Commercial Applications

In industry, this technology is a workhorse. It's used for branding logos onto promotional products, serializing parts for traceability, creating intricate architectural models, personalizing consumer goods, and producing high-end retail signage. Its ability to replicate the same design perfectly a thousand times over makes it essential for repeatable manufacturing.

3. Comparison with Traditional Methods

How does it stack up against older techniques?

| Feature | Laser Engraving | CNC Routing | Hot Branding |

|---|---|---|---|

| Precision | Extremely High | High | Low |

| Tool Wear | None (Non-Contact) | High (Bits wear out) | Low |

| Speed | Very Fast for detail | Slow for detail | Moderate |

| Versatility | Excellent | Good (Depth) | Poor (One design) |

| Setup Cost | Low (Digital file) | Moderate (Tooling) | High (Custom iron) |

What are the Main Benefits of Laser Engraving on Wood?

Your current production process is plagued with issues. Tooling costs are high, setup for new designs takes hours, and the final quality is inconsistent. You're losing time and money while struggling to keep up with smaller, more agile competitors who can offer more complex and personalized products. It feels like you're falling behind.

The primary benefit of laser engraving is its combination of unmatched precision and operational efficiency. Because it's a non-contact, digitally controlled process, there are no tooling costs or wear. It offers incredible speed for complex designs, produces a permanently crisp and clean mark, and allows for instant changes between jobs. This reduces waste, lowers labor costs, and increases overall production throughput.

For a purchasing manager, the benefits translate directly to the bottom line. It's about efficiency, quality, and cost savings.

1. Unmatched Precision and Detail

A laser beam can be focused down to a fraction of a millimeter. This allows you to engrave incredibly detailed logos, small text, and even photographic images with a clarity that no mechanical tool can replicate. This high level of quality control means fewer rejected parts and a more premium final product.

2. Speed and Efficiency

For surface marking and intricate patterns, a laser's galvanometer (scanner) system can move the beam at incredible speeds. A complex logo that might take a CNC router several minutes to carve can be engraved by a laser in mere seconds. This massive increase in throughput is crucial for large-scale production runs.

3. Non-Contact and No Tooling

Since nothing physically touches the wood, there is no tool wear, no need for replacement bits, and no mechanical stress on the material. More importantly, switching from one design to another is as simple as opening a new file on a computer. This eliminates downtime and the high cost associated with creating and managing physical dies or branding irons.

What is Truly the Ideal Wood for Laser Marking and Engraving?

You're looking at online guides that give you a "Top 5" list of woods for laser engraving. You diligently source alder or cherry, expecting perfect results. But the engravings are inconsistent, with ugly flare-ups and uneven coloring. You've followed the expert advice, but it's not working, leaving you frustrated and confused.

The ideal wood for engraving isn't a specific species, but any wood that is highly consistent. The true enemy of good engraving is unpredictability—hidden resin pockets that cause flare-ups and dense winter growth rings that engrave differently than lighter summer rings. Therefore, the "best" woods are those with low resin content, a uniform and straight grain, and a light, even color, because they provide a predictable canvas.

This is the most critical lesson in professional wood engraving. We steer clients away from the "what species?" question and toward the "what characteristics?" question.

1. The Myth of the "Perfect" Species

Artists love cherry for its rich color and maple for its smooth surface. But from a manufacturing standpoint, a cheap, "boring" piece of basswood that is perfectly uniform is infinitely better than an expensive piece of figured maple with unpredictable grain. We don't source for beauty; we source for predictability, because that's what allows for automation and profitability.

2. Key Characteristics of 'Good' Engraving Wood

When sourcing lumber, ignore the name and look for these traits:

- Low Resin/Sap Content: This is the #1 cause of flare-ups and uneven, dark patches. Woods like alder and basswood are excellent choices because they are very clean.

- Uniform Grain: Wood with minimal difference between early and late growth rings (like maple) engraves more evenly than woods with dramatic grain (like oak).

- Light Color: A lighter surface provides better contrast for the dark char of the engraving, making the final design pop.

3. Popular Choices (Judged by Consistency)

Here are common woods, evaluated from a manufacturing perspective:

| Wood Species | Engraving Contrast | Consistency | Risk Factor |

|---|---|---|---|

| Alder | Excellent | Very High | Low (Very low resin) |

| Basswood | Good | Very High | Low (Very uniform and soft) |

| Maple | Excellent | High | Low (Hard and dense, but clean) |

| Cherry | Excellent | Good | Medium (Can have resin pockets) |

| Pine | Good | Poor | High (Very resinous, unpredictable) |

What Factors Should I Consider When Laser Engraving on Wood?

You've sourced a consistent batch of wood and programmed the design perfectly. You run the first piece, and it looks great. You run the tenth piece with the exact same settings, but the engraving is lighter and less defined. You're baffled by the inconsistency and worried you can't guarantee quality across the entire production run.

Beyond the wood itself, the three most critical factors are the laser's Power, Speed, and Focus. Power determines the depth, Speed controls the darkness, and Focus dictates the sharpness of the line. These three settings work together and must be finely tuned for each specific type of wood. A slight variation in wood density or moisture content may require minor, real-time adjustments to maintain consistency.

Think of these settings as a balancing act. Adjusting one requires you to consider the others.

1. Power and Speed: The Core Relationship

These two are opposites. Increasing power makes the mark darker and deeper. Increasing speed makes the mark lighter and shallower. The goal is to find the "sweet spot": the highest possible speed you can run at while using the minimum amount of power needed to get the desired darkness. Running too slow with too much power "overcooks" the wood, causing excessive char and bleeding.

2. The Critical Importance of Focus

An out-of-focus laser beam is like a blurry photograph. The energy is spread out, resulting in a wide, weak line that doesn't engrave cleanly. The laser's focal point must be set precisely to the surface of the wood. Even a slight warp in a piece of wood can throw off the focus and ruin the result, which is why a flat, stable material is so important.

3. Air Assist: The Unsung Hero

A constant stream of compressed air1 directed at the engraving point is essential. It does two crucial things: first, it blows away the smoke and vaporized wood particles, preventing them from clouding the laser beam and reducing its power. Second, it extinguishes the flame front on the wood's surface, preventing flare-ups and reducing char, which results in a much cleaner engraving2.

Conclusion

When it comes to laser engraving wood for production, the conversation must shift away from the artistic ideal of a "perfect species." The true art lies in the science of sourcing and processing. Success is not defined by a list of popular woods, but by the relentless pursuit of consistency. By prioritizing timber with low resin, uniform grain, and predictable density, you create a stable canvas. This allows you to harness the laser's power, speed, and focus to deliver repeatable, high-quality results at scale, turning a craft into a profitable manufacturing process.

FAQs

Q1: So, if the species doesn’t matter as much, what should I tell my supplier I'm looking for?

A: Instead of asking for a specific species like "cherry," ask for "a light-colored hardwood with a straight, uniform grain and low resin content." This language focuses on the characteristics that ensure consistent engraving results, which is what actually matters for production. Suppliers who understand industrial needs will know what to provide.

Q2: My engravings look faded or blurry on some parts of the wood. Is this a focus issue?

A: Most likely, yes. A blurry result is the classic sign of an out-of-focus laser. Ensure the wood is perfectly flat and that you've set the correct focal distance to the top surface. Even a slight warp in the material can be enough to throw the focus off and ruin the detail of the engraving.

Q3: What exactly is a "resin pocket" and why is it so bad for laser engraving?

A: A resin pocket is a small, dense deposit of sap within the wood. When the high-energy laser beam hits it, the resin instantly vaporizes and ignites, causing a "flare-up." This creates an uncontrolled burn that results in a dark, ugly scorch mark, ruining the consistency and detail of the engraving.

Q4: How does air assist help create a cleaner engraving?

A: Air assist directs a jet of compressed air right at the point where the laser meets the wood. It does two things: 1) It blows away the smoke and debris, allowing the laser beam to maintain full power. 2) It instantly extinguishes the tiny embers on the wood's surface, preventing excessive charring and resulting in a crisper, cleaner mark with less discoloration.

Q5: Is it better to do one deep pass or multiple light passes to engrave wood?

A: For most wood engraving (creating a dark mark, not deep cutting), one single pass is best. The goal is to find the right balance of high speed and low power to vaporize the surface cleanly. Multiple passes can increase the risk of charring and don't necessarily produce a better result for standard marking.

Q6: Why do my settings that worked perfectly yesterday produce a lighter mark today on the same type of wood?

A: This could be due to variations in the wood's moisture content or a dirty lens. Wood from a new batch might be slightly moister, requiring a touch more power. More commonly, residue from the wood smoke has built up on your laser's lens, scattering the beam and reducing its power. Regular lens cleaning is critical for consistency.

Q7: Can I laser engrave on stained or finished wood?

A: Yes, but you must be careful. The laser will vaporize the finish (stain, lacquer, varnish) first before it hits the wood. This can create toxic fumes, so excellent ventilation is non-negotiable. The finish will also affect the final color of the engraving. Always test on a scrap piece first.

Q8: What's the difference between engraving and marking on wood?

A: In laser terms, engraving removes material to create depth. Marking is a surface-level process that changes the color of the material without significant depth. With wood, the two are often used interchangeably because the laser vaporizes the wood (engraving) to create a dark char (a mark).

Q9: Why does oak engrave so unevenly?

A: Oak has a very pronounced and uneven grain structure, with very hard, dense winter growth rings and much softer, porous summer growth rings. The laser interacts differently with these two densities, causing the engraving to look light and faded on the hard rings and dark and deep on the soft rings, resulting in an inconsistent, "striped" appearance.

Q10: Is MDF a good material for laser engraving?

A: MDF (Medium-Density Fiberboard) is excellent for consistency. Because it's an engineered product made of wood fibers and resin, it has no grain or natural defects. It engraves with a very uniform color and depth, making it a highly predictable and cost-effective material for applications where the look of natural wood grain is not required.