Troubleshooting

CO2 Laser Machine Problem Check and Repair

I. Problem Identification

Laser Output Problems:

Weak Laser Beam: If the laser beam appears faint or lacks the expected power, the first thing to check is the laser tube. Examine it for any signs of wear, such as cracks on the glass surface or discoloration. A discolored tube might suggest internal damage or gas leakage. Additionally, the power supply to the laser tube could be insufficient. Check the voltage settings and connections related to the tube.

Inconsistent Beam Quality:

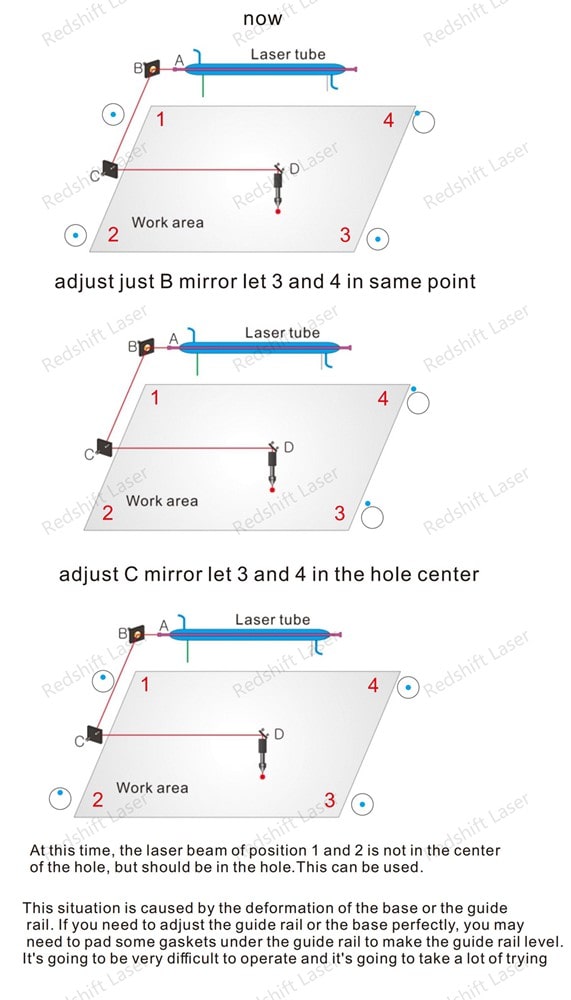

Fluctuations in the laser beam’s intensity or focus can be caused by issues with the optical path. Inspect the mirrors and lenses along the beam’s route. Dust, scratches, or misalignment of these optical components can lead to beam distortion. Use a soft, lint-free cloth to gently clean the mirrors and lenses, and check for proper alignment using alignment tools if necessary.

Power Supply Issues:

Machine Won’t Start: When the CO2 laser machine fails to power on, begin by examining the power cord and plug. Ensure they are properly inserted and not damaged. Then, check the power supply unit itself. Look for blown fuses, loose connections, or any signs of overheating. If a fuse is blown, replace it with the correct rating fuse after disconnecting the power.

Power Supply Issues:

If the machine experiences sporadic power cuts during operation, it could be due to a faulty power supply capacitor or a loose connection in the power circuit. Test the capacitors with a capacitance meter and tighten any loose wires or connectors.

Power Supply Issues:

Unsmooth Table Movement: If the cutting or engraving table doesn’t move smoothly, it can affect the quality of the work. Check the belts and pulleys that drive the table movement. A loose or worn belt can cause jerkiness. Tighten or replace the belt as needed. Also, inspect the guide rails and lubricate them if they seem dry or sticky.

Misaligned Laser Head: If the laser head is not properly aligned with the work surface, it can result in inaccurate cuts or engravings. Use alignment jigs or lasers to check and correct the alignment. This may involve adjusting the height and position of the laser head relative to the table.

II. Repair Procedures

Replacing a Damaged Laser Tube:

Preparation: Before replacing the tube, turn off and unplug the machine. Let it cool down completely to avoid burns. Gather the necessary tools, such as wrenches and screwdrivers.

Removal: Carefully disconnect the electrical and gas connections from the old tube. Loosen the mounting brackets and gently remove the tube from the machine. Handle it with care as it is fragile.

Installation: Insert the new tube into the correct position, making sure it is properly seated. Reconnect the electrical and gas lines, tightening the connections securely. Follow the manufacturer’s instructions for any post-installation adjustments.

Fixing Power Supply Problems: Fuse Replacement: As mentioned earlier, if a fuse is blown, identify the correct replacement fuse based on the machine’s specifications. Insert it into the fuse box and test the machine.

Component Repair/Replacement: If the power supply issue persists after replacing the fuse, further diagnosis is needed. This may involve testing individual components like capacitors, diodes, and transistors with a multimeter. Replace any faulty components as required.

Solving Movement and Alignment Problems:

Belt and Pulley Adjustment: To tighten a loose belt, loosen the motor mounting bolts slightly, move the motor to increase the tension, and then retighten the bolts. Check the pulley alignment as well to ensure smooth rotation.

Alignment Correction: When realigning the laser head, use the alignment tools to make precise adjustments. This may involve turning adjustment screws to change the height and position of the head. After adjustment, perform a test run to confirm the accuracy of the alignment.

By carefully following these problem identification and repair procedures, most common issues with CO2 laser machines can be resolved, ensuring the smooth operation and high-quality output of the equipment.

Co2 Laser Machine - how to adjust laser beam?

Share to:

Get in Touch

If you have any problems, please contact us!