Vision Laser Cutter for Lace

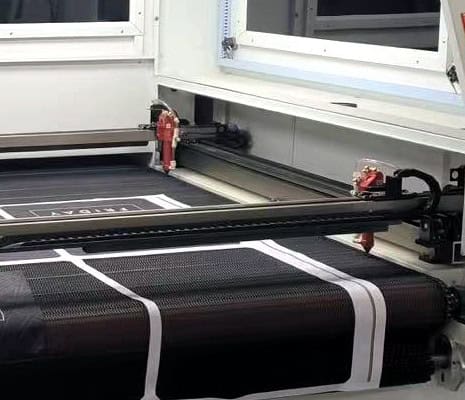

Redshift Vision Laser Cutting Machine integrates high-definition CCD vision recognition and CO₂ laser technology to achieve precise, automated cutting of lace, embroidered and printed fabrics. Say goodbye to manual trimming, material waste, and inaccurate edges.

Machine Overview

REDSHIFT Model: 1612 / 1812 / 1620 / 1820

The Redshift Vision Laser Cutting Machine is engineered for precise, high-speed processing of lace and embroidered textiles.

By integrating a CCD camera vision system with CO₂ laser cutting technology, the system automatically detects fabric contours, recognizes warp knitting lace or printed or stitched patterns, and executes accurate cutting paths – ensuring clean, sealed edges and zero material distortion.

This solution is ideal for manufacturers requiring consistent accuracy and efficiency in lace trimming, embroidery patch cutting, bridal wear, and decorative textile production.

Core Technology

CCD Vision Recognition System

The integrated high-resolution CCD camera captures real-time images of the fabric surface.

Redshift’s Vision software analyzes the contours and automatically converts them into vector paths for laser cutting.

- Automatic detection of lace and embroidery outlines

- Instant pattern matching without manual positioning

- Adaptive cutting for lace, printed, woven, or irregularly shaped materials

CO₂ Laser Cutting Precision

The sealed CO₂ laser source provides a stable beam and uniform energy distribution, achieving:

- Cutting accuracy ±0.1 mm

- Smooth, sealed edges with no fraying or burnt marks

- Non-contact cutting - no mechanical stress or fabric deformation

- Consistent performance on thin, delicate, and elastic materials

Smart Control Software

Developed for textile processing, Redshift Laser software allows:

- Real-time image recognition and contour tracking

- Automatic nesting and layout optimization to minimize material waste

- Custom parameter settings for different fabric thicknesses

- Compatibility with multiple design file formats: AI, PLT, DXF, BMP, JPG

Videos

Watch the RedShift Vision Laser Cutting of Lace in Action

Specifications

Main Technical Specifications of the RedShift Vision Laser Cutter Model: 1612 / 1812 / 1620 / 1820

| Working Area (W x L) | 1600mm x 1200mm / 1600mm x 2000mm/ 1800mm x 1200mm /1800mm x 2000mm (support customization) | |

| Laser source | CO2 glass laser tube / CO2 RF metal laser tube | |

| Laser power | 150W | |

| Working table | Conveyor working table | |

| Cutting speed | 0-1200mm/s | |

| Acceleration speed | 1000~10000mm/s2 | |

| Mechanical control system | Belt transmission / Rack & pinion transmission and servo motor driven | |

| Machine structure | Open type / Fully closed | |

| File format | DST, DXF, AI, PLT, BMP, etc. | |

| Power supply | 220V, 50Hz | |

Hightlights

Highlights of the RedShift Dual Head Vision Laser Cutting System

For the basic two laser heads cutting machine, the two laser heads are mounted in the same gantry, so they can only be used for the same patterns cutting. While for dye sublimation products, there are always many different types of print pieces, big pieces, or small pieces, all the pieces are different such as jerseys front, back, sleeves. The independent dual heads can cut different designs at the same time; so, it increases the cutting efficiency and production flexibility at the largest degree. Output increase ranges from 30% to 50% depends on what you cut.

Outline Contour Detection

Templates

Photo Digitize

The motor-controlled automatic feeding system avoids the influence of external force dragging, overcomes the elastic characteristics of the printed fabric, and ensures the fabric without deformation during the feeding process.

The unique automatic rectification function keeps the error of continuous feeding within 5mm, achieving continuous, smooth and precise processing for roll fabrics.

24 million pixel HD camera

Full-format scanning (1600X2500) with a 24 megapixel HD camera for fast and accurate identification,continuous cutting for roll of fabrics.

Accurately identify image position and contour through the vision system, and automatically produce cutting graphics for precise cutting with an error of less than 0.5mm.

Applications

Application Sectors of the RedShift Dual Head Vision Laser Cutting System

GET IN TOUCH WITH US →

Contact RedShift now to get a further information of how our laser solutions help increase your cutting workshop productivity and efficiency.