You're told that CO2 lasers are the ultimate solution for cutting synthetic fabrics because they create a perfectly sealed, no-fray edge. But on the factory floor, reality hits. Your sewing machine operators are reporting more broken needles. The assembly line is slowing down, and the final garments have seams that feel uncomfortably stiff. Suddenly, this single "advantage" is creating expensive bottlenecks and compromising the quality of your end product.

The “perfect” sealed edge from a laser is often misunderstood. While the beam cleanly prevents fraying by fusing the fibers, it doesn’t create the stiff, brittle edge many assume. A properly calibrated CO₂ laser forms a smooth, flexible boundary that feeds through sewing machines without causing needle deflection or breakage. The real focus is process control: with balanced power, speed, and ventilation settings, you can achieve fast, precise cutting while maintaining excellent drape, soft handfeel, and high sewing efficiency.

I remember working with a large sportswear manufacturer who was thrilled to switch to laser cutting for their polyester athletic shirts. They loved the speed and the clean edges. But a month later, I got a frustrated call from their production manager. Their sewing line, which was their most labor-intensive department, had slowed down by 15%. Needles were snapping, and operators were struggling to feed the stiff, laser-cut pieces through the machines. We had to go in and help them re-calibrate their laser settings—slightly lowering the power and increasing the speed—to create a "softer" seal. It was a crucial lesson: focusing only on the efficiency of the cutting stage can kill your overall workflow.

Is Laser Cutting the Future Trend for All Garments?

You see cutting-edge fashion and high-performance sportswear using intricate laser-cut details. It seems like the entire industry is moving in this direction, and you feel the pressure to keep up. But you're concerned about whether this trend is just a fleeting fad or a fundamental shift in production. Investing in the technology feels like a risk if the trend doesn't last.

Laser cutting is a durable trend in the garment industry, especially for synthetic fabrics, because it solves long-standing issues with speed, precision, and design freedom. It allows for complex patterns, "no-sew" applications, and perfectly clean edges that are impossible with traditional methods. While it won't replace all cutting methods, its role in creating detailed, high-value, and technical garments is growing and here to stay.

Why This Trend Has Staying Power

For a purchasing manager like John, it's vital to distinguish between a short-lived style and a long-term manufacturing technology. Laser cutting falls firmly into the latter category.

1. Unmatched Design Intricacy

Traditional die-cutting is limited to simple shapes. Lasers, however, are guided by a digital file, meaning they can cut almost any design, no matter how complex. This allows designers to create fine mesh-like ventilation patterns, intricate lace effects on polyester, and precise decorative cutouts that define modern athletic wear and fast fashion.

2. The Rise of "No-Sew" Technology

In technical outerwear and sportswear, lasers are used to cut and seal synthetic panels that are then bonded together with thermal adhesive tape instead of being sewn. This creates a completely flat, waterproof, and chafe-free seam. This is a functional benefit that traditional manufacturing cannot easily replicate.

3. Speed and Consistency for Mass Customization

With a laser, switching from one pattern to another takes seconds—you just load a new design file. There is no need to create and swap out expensive metal dies. This flexibility is perfect for the modern market's demand for smaller batches and more customized products, allowing a manufacturer to be more agile.

What Are the Real Advantages of Laser Cutting Garments?

You're evaluating whether to bring a laser cutter into your production line. Marketing materials are full of buzzwords like "speed," "precision," and "sealed edges." You're skeptical and need to know if these benefits translate into real, measurable gains in your workflow or if they create new, hidden problems that vendors don't talk about.

The primary advantages of laser cutting garments are its unmatched precision for complex designs and the elimination of fraying on synthetic fabrics. This leads to less material waste and a cleaner finished product. However, as we've discussed, the "sealed edge" benefit must be carefully managed to prevent downstream issues in sewing and assembly, which can impact overall efficiency and garment quality.

A Balanced View for Production Managers

Let's cut through the marketing hype. A laser is a tool, and its advantages depend on how you use it. For a professional concerned with the entire production line, a balanced view is critical.

1. Advantage: Precision and Repeatability

A laser beam has a tiny spot size (around 0.1mm), allowing it to cut shapes with extreme detail and sharp corners. Every piece cut from the same digital file is identical. This precision reduces errors and ensures perfect panel matching during sewing, which is especially important for complex, multi-part garments.

2. Hidden Cost: The "Perfect" Edge Problem

Here is the core issue. The laser melts polyester, nylon, and other synthetics, creating a hard bead of plastic at the edge. A sewing machine needle that repeatedly strikes this hard edge will deflect, leading to skipped stitches, or worse, break. This forces operators to slow down, increasing labor costs and creating a bottleneck that can wipe out the time saved during the cutting phase.

3. Impact on Garment Drape and Feel

That hard sealed edge doesn't just affect sewing; it affects the final product. A seam made from two laser-cut edges can feel stiff and even abrasive against the skin. This can ruin the drape and flow of a lightweight garment, making it less comfortable for the wearer. For high-quality apparel, this is a significant drawback.

Manufacturing Method Comparison

| Feature | Mechanical Die Cutting | CO2 Laser Cutting |

|---|---|---|

| Tooling Cost | High (custom die for each pattern) | None (digital file) |

| Edge Finish (Synthetics) | Raw, Prone to Fraying | Sealed, No Fraying |

| Design Complexity | Low to Medium | Very High |

| Seam Pliability | High (soft edge) | Low (stiff, beaded edge) |

| Sewing Needle Wear | Low | High (due to hard edge) |

| Best Use Case | High volume of simple, repeating shapes. | Complex patterns, prototypes, flexible batches. |

How Do You Choose the Right Garment Laser Cutting Machine?

Facing a sea of machine options, you're trying to choose the right laser cutter for your garment production. The technical specifications are overwhelming, and you're afraid of making a costly mistake. Buying a machine that's underpowered, oversized, or lacking key features could cripple your efficiency instead of improving it.

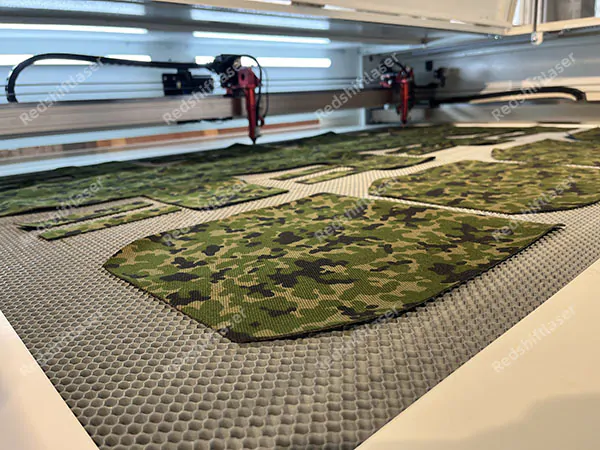

To choose the right laser cutter for garments, focus on three areas. First, select a CO2 laser with a power of 60-100W, which is enough for fabrics without creating an overly hard edge. Second, ensure the machine has a large enough bed with a camera system for pattern recognition and material saving. Finally, a conveyor system is essential for roll-fed, automated production.

Matching Machine Features to Garment Production Needs

The right machine is one that solves problems, not creates them. For John's perspective, this means focusing on features that boost overall throughput, not just cutting speed.

1. Laser Power: Less Can Be More

While higher power means faster cutting, for fabrics it can create a harder, thicker sealed edge. A laser in the 60W to 100W range is the sweet spot. It's powerful enough to cut quickly but gives you the fine control needed to create a "soft seal" that is less likely to cause sewing problems. Good software control over power output is critical.

2. Vision System: Your Key to Minimizing Waste

An overhead camera (or "vision system") is a non-negotiable feature for serious garment production. It does two things. First, it can automatically detect the contours of a piece of fabric to nest patterns efficiently, saving expensive material. Second, for printed fabrics, it recognizes registration marks to perfectly align the cut path with the print, eliminating misalignment errors.

3. Conveyor Bed: The Heart of Automation

A static bed requires you to manually load and unload every sheet of fabric. This is a major labor cost and production bottleneck. A conveyor system automatically feeds the fabric from a roll, cuts a section, and then advances the material for the next cut. This enables continuous, unattended operation and is essential for any significant production volume.

What Are the Best Fabrics and Technologies for Laser Cutting?

You want to innovate with laser cutting, but you're not sure which materials are safe or effective. Using the wrong fabric could result in poor cut quality, toxic fumes, or even damage to your machine. You need clear guidance on what works and what advanced techniques are available to gain a competitive edge.

The best fabrics for laser cutting are synthetics like polyester, nylon, microfiber, fleece, and felt, as they produce a clean, sealed edge. Natural fibers like cotton and wool can also be cut, but they will char slightly and not self-seal. It's critical to avoid any material containing PVC. Advanced techniques include laser etching for texture and kiss-cutting multi-layered fabrics.

From Basic Cutting to Advanced Applications

Success lies not just in cutting, but in leveraging the laser's full capabilities.

1. Ideal Materials: Synthetics

Polyester, nylon, and other polymers are ideal. They react to the laser's heat by melting and vaporizing, which results in the sealed edge. This is perfect for sportswear, technical apparel, and any application where fraying is a major concern. The key is to test different settings to find the minimum power needed for a clean cut to keep the edge as soft as possible.

2. Workable Materials: Natural Fibers

You can absolutely laser cut cotton, linen, silk, and wool. However, these materials behave differently. Instead of melting, they burn or vaporize, leaving a slightly discolored or "charred" edge. This can be a desirable aesthetic on some products (like laser-etched denim) but may be undesirable on others. They will not have a fray-proof seal.

3. Advanced Technique: Kiss-Cutting and Etching

Kiss-cutting is a technique where the laser cuts through the top layer of a multi-layered material without cutting the bottom layer. This is used for creating multi-layered appliqués or for cutting the vinyl for heat-transfer graphics. Laser etching (or marking) uses low power to remove just the surface of a fabric, creating patterns, textures, or a "worn" look on denim without compromising the fabric's integrity.

Conclusion

Embracing laser cutting technology in garment manufacturing offers huge advantages in design freedom and precision. However, true production excellence comes from looking beyond the surface-level benefits. The "perfectly sealed edge," while a powerful selling point, brings a hidden cost in sewing and final garment quality. By understanding that this edge can be a liability, and by choosing machines and processes that help manage its hardness, you can truly optimize your entire workflow. This balanced approach allows you to harness the laser's power without creating costly new problems on your assembly line.

FAQ: Laser Cutting Garments

Q1: Will laser cutting burn natural fabrics like cotton?

A: Instead of a clean melt like synthetics, natural fibers will have a slightly singed or charred edge. The amount of discoloration depends on the fabric and laser settings. For many designs, this is minimal and acceptable, but it won't be a clear edge.

Q2: What is "air assist" and why is it important for fabric?

A: Air assist is a stream of compressed air directed at the cutting point. For fabrics, it's crucial as it blows away heat and flammable gases, preventing flare-ups and reducing charring or melting, resulting in a cleaner cut.

Q3: Can a laser cutter work with stretchy fabrics like Lycra or Spandex?

A: Yes, but the fabric must be laid flat without any tension. If the material is stretched while being cut, the finished piece will distort and shrink back to the wrong size once the tension is released. A conveyor bed system designed for textiles helps feed these materials smoothly.

Q4: How do you handle the fumes from laser cutting synthetic fabrics?

A: A high-quality fume extraction and filtration system is mandatory. Cutting polymers releases smoke and volatile organic compounds (VOCs). An extractor removes these from the cutting area, ensuring operator safety and preventing residue from settling on the machine's optics.

Q5: Is laser cutting faster than using a traditional cutting plotter with a knife?

A: For straight lines, a knife plotter can be faster. However, for intricate patterns, curves, and sharp corners, the laser is significantly faster because it doesn't have to slow down or lift and pivot. The laser's overall throughput is often higher due to its design versatility.

Q6: What is a "nesting" software and is it important?

A: Nesting software is extremely important. It's a program that automatically arranges your pattern pieces on the fabric in the most efficient way possible to minimize waste. For expensive technical fabrics, good nesting software can lead to significant cost savings.

Q7: Can I engrave patterns onto fabric without cutting all the way through?

A: Yes, this is called laser etching or marking. By using a very low power setting, the laser will only remove the top layer of dye or fibers, creating a tonal pattern. This is very popular for decorating denim, fleece, and microfiber.

Q8: Why is a camera system so highly recommended for garment cutting?

A: A camera system automates two critical tasks: it can recognize the boundaries of an irregularly shaped piece of material to maximize its use, and it can find printed registration marks to ensure the laser cut is perfectly aligned with a printed graphic on the fabric.

Q9: Does the sealed edge from a laser cutter ever wash out or soften over time?

A: No, the sealed edge is a permanent physical change to the fabric where the polymer has melted and re-solidified. It will not soften with washing. This is why controlling the hardness of the seal during the cutting process is so important for garment comfort.

Q10: What materials should I absolutely never try to laser cut?

A: Never cut any material containing chlorine, such as PVC (polyvinyl chloride), vinyl, or common artificial leather. When heated, these materials release corrosive hydrochloric acid gas, which is extremely toxic to breathe and will destroy your laser machine.