You're looking at different ways to finish embroidered patches, comparing the classic stitched border of a merrow machine to the clean, sharp edge from a laser. You see it as a simple aesthetic choice, a matter of style for your final product. But this narrow view is hiding a massive inefficiency in your production line. You're focusing on the final look while ignoring the slow, labor-intensive bottleneck that traditional methods create, costing you time and limiting your design potential.

No, laser cutting is not just about a cleaner edge. Its real value is in revolutionizing the entire production workflow. Unlike merrowing, which is a separate, post-production sewing step, a laser cuts the patch shape and perfectly seals the edge in a single, automated action. This process consolidation eliminates a major bottleneck, removes the limitations of mechanical stitching on complex designs, and opens the door to greater creative freedom and manufacturing efficiency.

This isn't just theory; it's a problem I see constantly. I once worked with a supplier for a major athletic brand who landed a huge order for a new, complex shield-shaped patch with sharp internal corners. Their bank of merrowing machines, the industry standard, couldn't handle it. Operators were struggling, rejection rates were soaring, and they were falling behind schedule. They were looking at investing in highly specialized sewing machines, but I told them they were trying to solve the wrong problem. The issue wasn't the sewing; it was the entire multi-step process. We brought in a single laser cutter, and it changed their business. It cut and sealed the patch perfectly in one pass, eliminating the sewing bottleneck entirely. They met their deadline and could suddenly take on jobs they used to turn away.

Why Is Laser Technology A Game-Changer For Apparel Production?

You've built your production line on dependable, traditional methods like die-cutting and merrowing. They feel safe and familiar. But now, your clients are demanding more intricate designs, faster turnaround times, and smaller, more customized orders. Your rigid, multi-step process is slow, labor-intensive, and simply cannot keep up with the pace of modern fashion and branding, threatening your competitive edge.

Laser technology is a game-changer because it transforms a physical, multi-step process into a single, digital one. It offers unmatched design freedom to cut any shape, no matter how complex, directly from a design file. This eliminates the cost and lead time of creating physical dies and removes the mechanical limitations of a sewing needle. It allows for a fast, agile, and highly efficient workflow from concept to finished product.

For a purchasing manager like John, understanding the shift from a physical to a digital workflow is key to appreciating the ROI.

1. Eliminating Physical Tooling

Traditional die-cutting requires a custom metal die for every single patch design. This means significant upfront costs, long lead times for die creation, and physical storage for all the tools. A laser cutter uses a digital file (like a PDF or AI file) as its "die," meaning you can switch between designs instantly with zero tooling costs.

2. Consolidating Production Steps

The traditional patch workflow is fragmented: print/embroider the fabric, roughly cut it out, then move it to a sewing station for a skilled operator to merrow the edge. A laser system with vision recognition can identify the patch outline and perform a perfect contour cut and edge seal in one automated step, drastically reducing material handling and labor.

3. Enabling On-Demand Customization

Because there is no physical setup, lasers are perfect for short runs and on-demand production. You can produce a single, unique patch just as cost-effectively as a thousand. This agility is impossible with die-cutting and merrowing, which rely on economies of scale.

Workflow Comparison: Traditional vs. Laser

| Step | Traditional Workflow | Laser Workflow |

|---|---|---|

| 1. Design | Create simple, merrow-friendly shape | Create any shape, simple or complex |

| 2. Tooling | Order & wait for expensive metal die | None (use digital file) |

| 3. Cutting | Die-cut the rough shape | Cut & seal final shape in one step |

| 4. Finishing | Manually sew merrowed border | (Step eliminated) |

| Lead Time | Days to Weeks | Minutes to Hours |

| Labor | High (Cutting + Skilled Sewing) | Low (Single Operator) |

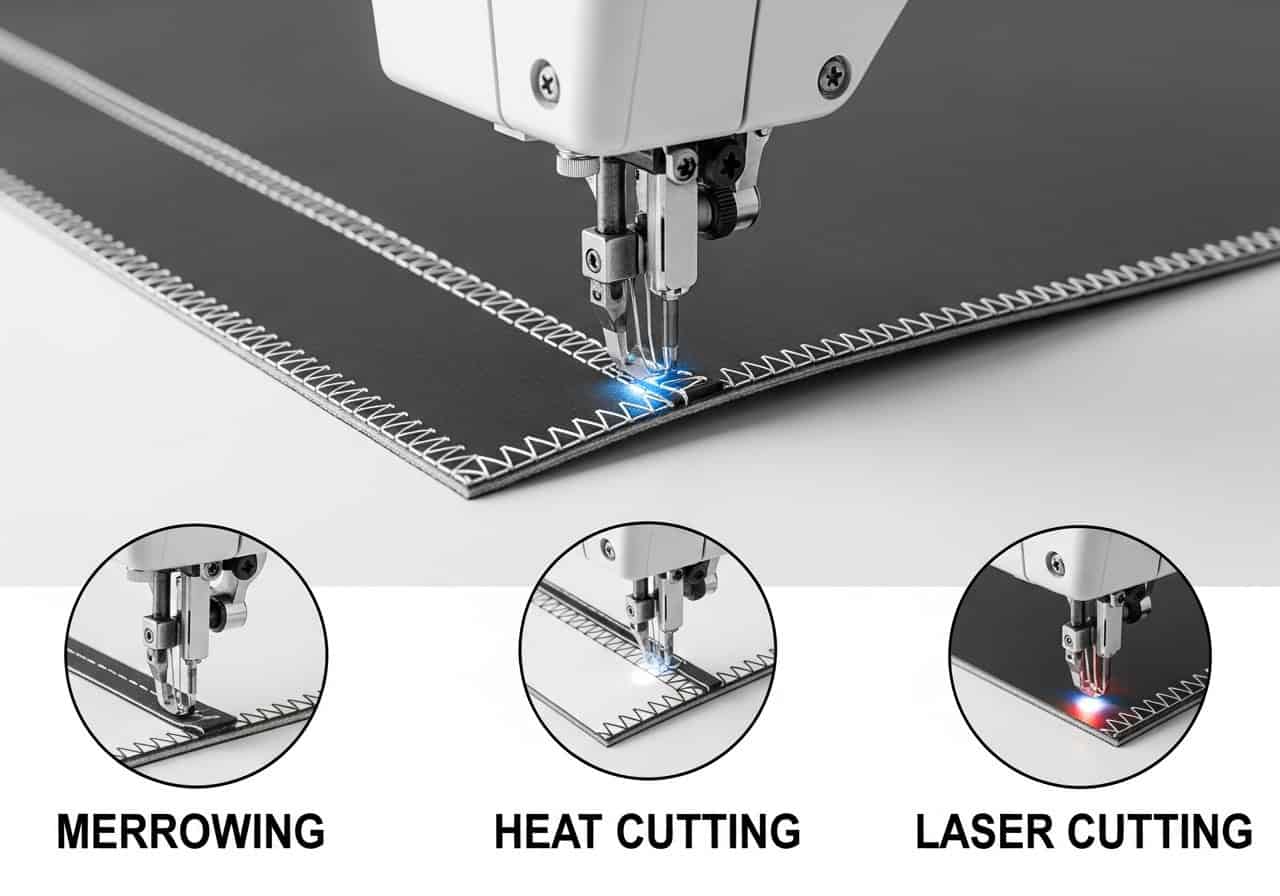

What Are the Main Methods for Finishing Patches?

As a purchasing manager, you're evaluating different equipment for finishing patches. You see options like merrow machines, heat knives, and lasers. On the surface, they all aim to do the same thing: create a finished edge. This makes it difficult to understand the fundamental differences in capability and why one might be a significantly better long-term investment for your production line.

The three main methods are merrowing, heat cutting, and laser cutting. Merrowing uses a specialized sewing machine to create a classic, stitched border but is limited to simple shapes. Heat cutting uses a hot knife to melt and seal synthetic fabrics but is imprecise and manual. Laser cutting uses a focused beam of light to cut and seal the edge with unparalleled precision on any shape, making it the most versatile and efficient method.

Each method has its place, but they are not interchangeable. Understanding their core strengths and weaknesses is crucial for making the right procurement decision.

1. The Merrowed Edge: The Traditional Standard

This is a serged edge created by an overlock stitch. It gives a classic, dimensional look.

- Strengths: Durable, traditional aesthetic that many customers recognize.

- Weaknesses: Requires a skilled operator. It cannot navigate sharp corners, points, or internal cutouts. The process is slow and entirely separate from cutting.

2. The Heat-Cut Edge: The Simple Sealer

A heated blade or wire is used to melt through synthetic materials like polyester.

- Strengths: Inexpensive and effectively prevents fraying on basic synthetics.

- Weaknesses: Very imprecise, often leaving a thick, hard bead of melted plastic. Not suitable for detailed shapes or natural fibers. It's a manual process prone to inconsistency.

3. The Laser-Cut Edge: The Modern Solution

A high-energy beam of light vaporizes the material, cutting the shape and melting the edge simultaneously.

- Strengths: Extremely precise, clean, and perfectly sealed edge. Can cut any shape, including sharp corners and internal holes. It is a fast, automated, and non-contact process.

- Weaknesses: Higher initial equipment investment.

Feature Comparison: Finishing Methods

| Feature | Merrowing | Heat Cutting | Laser Cutting |

|---|---|---|---|

| Precision | Low | Low | Very High |

| Shape Complexity | Simple only (rounded corners) | Simple only | Unlimited |

| Edge Quality | Stitched, bulky | Melted, often hard | Clean, sealed, no fraying |

| Speed | Slow (manual sewing) | Medium (manual) | Very Fast (automated) |

| Automation | No | No | Yes (Vision Systems) |

How Does a Laser Actually Cut and Seal Patches?

You're considering a laser, but the technology feels like a black box. You understand mechanical cutting, but how can a beam of light produce a perfectly finished patch? This uncertainty makes it hard to trust the process and explain its benefits to your team, raising concerns about reliability, operator training, and material compatibility before you're willing to invest.

A laser cuts patches using a process of rapid vaporization. The focused beam of light is so intense that it instantly turns the fabric material from a solid into a gas, leaving an incredibly fine cut line. For synthetic materials like polyester, the residual heat from this process simultaneously melts the fibers along the edge, creating a perfect, clean seal that will not fray.

The process is highly controlled and can be broken down into a few key components.

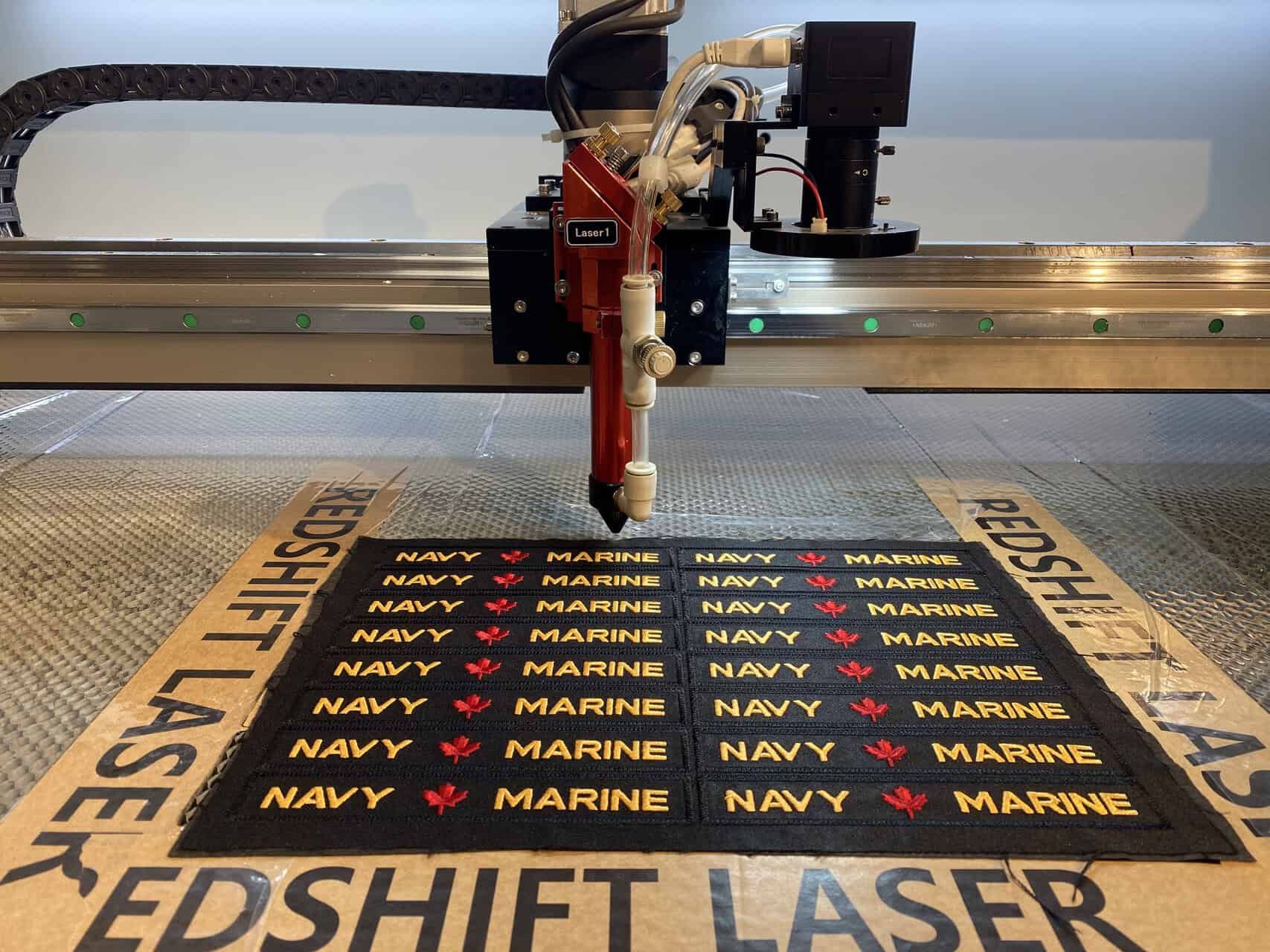

1. Vision Registration System

Modern laser cutters for patches are equipped with a camera mounted on the cutting head. This camera scans the material, automatically recognizes the outline of the printed or embroidered patch, and tells the laser exactly where to cut. This eliminates the need for precise placement of the material, which dramatically speeds up the workflow and reduces errors.

2. The CO₂ Laser Beam

The workhorse for cutting textiles is a CO₂ laser. It emits a beam of light in the infrared spectrum that is highly absorbed by organic materials and plastics. This efficient energy absorption is what allows it to vaporize the material so quickly and cleanly, without putting any physical stress on the fabric.

3. Motion Control System

The laser head is mounted on a gantry that moves with extreme speed and precision across the cutting area. The system follows the digital path from your design file, moving the laser beam to trace the outline of the patch. The accuracy of this system is what allows for the creation of incredibly intricate details.

How Do You Choose the Right Laser Cutting Machine?

You're convinced of the benefits, but now you face a confusing market of laser machines. They come in different sizes, power levels, and price points. You don't know what features are essential versus what are just expensive add-ons. You're worried about making the wrong choice, either overspending on a machine with capabilities you don't need or underspending and ending up with a system that can't meet your production demands.

Choosing the right laser cutter depends on three key factors: bed size, laser power, and essential features. The bed size must be large enough to accommodate your fabric rolls or sheets. For patches and textiles, a laser power of 60-100 watts is typically sufficient. Most importantly, ensure the machine has a high-quality Vision Registration System (camera) for automatic contour cutting, as this is the key to an efficient patch production workflow.

Don't get lost in the jargon. Focus on the specifications that directly impact production efficiency and quality.

1. Bed Size and Type

- Flatbed: The most common type. Ensure the working area is larger than your typical material size. A pass-through feature (doors on the front and back) is valuable for handling oversized rolls.

- Conveyor Bed: For fully automated roll-to-roll production, a conveyor bed automatically feeds the material through the machine. This is ideal for very high-volume, unattended operation.

2. Laser Power (Watts)

More power isn't always better. Power equals speed, but for cutting textiles, precision is more important.

- 60-80W: An excellent range for cutting most patch materials, including embroidered twill and polyester fabrics. Provides a great balance of speed and control.

- 100-130W: Ideal for thicker materials or if you need maximum cutting speed for very high-volume production.

3. Must-Have Features

- Vision Registration Camera1: This is non-negotiable for patch making. It automates the cutting process2, compensates for any distortion in the material, and ensures perfect cuts every time.

- Fume Extraction3: Cutting fabric produces smoke and fumes that must be safely removed. A powerful fume extractor4 is essential for operator safety and keeping the laser's optics clean.

- Air Assist5: A jet of compressed air points at the cutting location. This blows away debris, prevents flare-ups, and results in a cleaner cut edge6.

Conclusion

The choice between finishing methods for patches is far more than an aesthetic one. While the classic merrowed border has its place, it represents a dated, inefficient workflow full of mechanical limitations. Laser technology offers a fundamental shift. It's not about replacing one edge style with another; it's about consolidating an entire production process, eliminating bottlenecks, and unlocking a level of design freedom that was previously impossible. For any modern apparel manufacturer, embracing the laser isn't just an upgrade—it's a necessary evolution for a more agile, efficient, and creative future.

Relate

FAQs

Q1: What is the main advantage of laser cutting patches over merrowing?

A: The main advantage is process consolidation. A laser cuts the shape and seals the edge in a single automated step, eliminating the separate, labor-intensive sewing process required for merrowing and removing a major production bottleneck.

Q2: Is a merrowed edge more durable than a laser-cut edge?

A: Not necessarily. A merrowed edge is a thread stitched around the border. A laser-cut edge on synthetic material is a perfectly sealed, melted edge that cannot fray. Both are very durable, but the laser seal is integrated into the patch material itself.

Q3: Can a merrow machine create complex shapes like a laser?

A: No. Merrowing is a mechanical sewing process that cannot navigate sharp internal corners, tight points, or intricate cutouts. This physical limitation restricts patch designs to simple, rounded shapes.

Q4: What is the purpose of the Vision Registration System (camera) on a laser cutter?

A: The camera automatically detects the outline of the embroidered or printed patch on the fabric. It then directs the laser to cut perfectly along this contour, compensating for any stretching or distortion in the material and ensuring high accuracy with minimal setup.

Q5: What laser power is best for cutting fabric patches?

A: For most textile and embroidered patch materials, a CO₂ laser with 60 to 100 watts of power provides an excellent balance of cutting speed and precision. Higher power is only needed for very thick materials or extreme production speeds.

Q6: Does laser cutting work on all types of fabric?

A: Lasers work exceptionally well on synthetic fabrics (like polyester, nylon) as they melt and seal the edge cleanly. They can also cut natural fibers (like cotton or wool), but these materials will not self-seal and may require a sewn border if fraying is a concern.

Q7: How does laser cutting reduce labor costs?

A: It replaces two separate, skilled jobs (a cutter and a sewing machine operator) with a single, highly automated process. One operator can often manage multiple laser machines, significantly increasing output per employee.

Q8: Do I need expensive metal dies for laser cutting?

A: No. The laser works directly from a digital design file (e.g., PDF, AI, DXF). This eliminates the cost, storage, and lead time associated with creating and managing physical cutting dies, allowing for instant design changes.

Q9: What is the difference between heat cutting and laser cutting?

A: Heat cutting uses a simple hot blade and is a manual, imprecise method best for straight lines, often leaving a thick, hard edge. Laser cutting uses a highly focused beam of light for an automated, extremely precise cut that produces a clean, soft, perfectly sealed edge on any shape.

Q10: Is fume extraction necessary when laser cutting patches?

A: Yes, absolutely. Cutting textiles vaporizes the material, creating smoke and fumes. A proper fume extraction system is essential for maintaining a safe work environment for the operator and protecting the laser's sensitive optics from residue.

-

Understanding the functionality of a Vision Registration Camera can enhance your knowledge of automated cutting processes. ↩

-

Exploring automation in cutting processes can reveal efficiency gains and innovations in manufacturing technology. ↩

-

Understanding fume extraction is crucial for ensuring safety and equipment maintenance in laser cutting processes. ↩

-

Exploring how fume extractors function can enhance your knowledge of safety measures in laser cutting, ensuring a healthier workspace. ↩

-

Discover how Air Assist enhances cutting precision and cleanliness, making it essential for efficient operations. ↩

-

Learn techniques and technologies that ensure a cleaner cut edge, improving product quality and reducing waste. ↩