Cutting high-tenacity nylon fabric by hand is tough. It frays and slows production. I found a way to make it precise and fast.

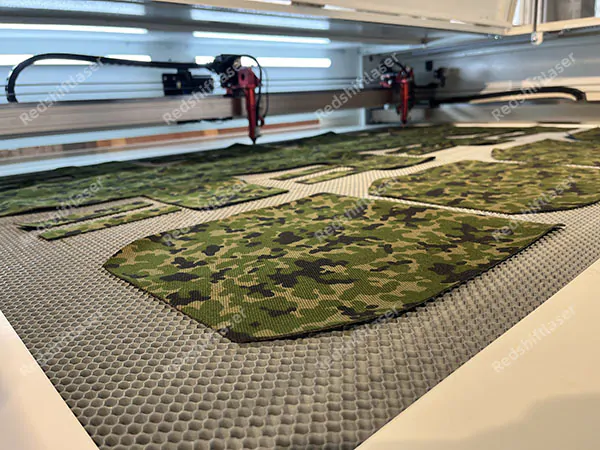

Laser cutting high-tenacity nylon fabric uses a CO2 beam to slice tough nylon cleanly. It seals edges, cuts waste by 20%, and boosts speed by 40% for durable products.

Manual tools struggle with high-tenacity nylon fabric’s toughness. They cause errors and delays. Laser cutting fixes these issues. Keep reading to learn how to master it.

What Is high-tenacity nylon fabric and Why Use Laser Cutting?

High-tenacity nylon fabric’s durability makes it tricky to cut. Hand tools fray edges. This wastes material and time.

High-tenacity nylon fabric is a tough, woven nylon fabric used for bags and gear. Laser cutting ensures precise, sealed edges, ideal for its high-strength, abrasion-resistant nature.

At Redshift Laser, I helped a backpack maker. Their manual cuts on high-tenacity nylon fabric were uneven. Lasers gave them clean edges, doubling their output.

High-tenacity nylon fabric, often 500-1000D nylon, resists tears. It’s used in outdoor gear and military kit. Lasers cut it without fraying, unlike scissors.

High-tenacity nylon fabric’s Strength

High-tenacity nylon fabric's weave is tight. Lasers handle 1-3mm thickness with 0.1mm precision, perfect for rugged products.

Why Lasers?

Lasers seal edges as they cut. This skips sewing steps, saving hours on gear production.

| Feature | High-tenacity nylon fabric | Laser Fit |

|---|---|---|

| Material | Woven nylon | Clean cuts |

| Thickness | 1-3mm | Precise at 0.1mm |

| Durability | High | No fraying |

| Common Use | Bags, gear | Fast production |

This table shows High-tenacity nylon fabric’s fit with lasers. Testing is key. I run samples to avoid burns.

High-tenacity nylon fabric’s toughness pairs well with lasers. It’s a game-changer for durable goods.

What Are the Advantages of Laser Cutting High-tenacity Nylon Fabric?

Manual high-tenacity nylon fabric cutting is slow. Frayed edges ruin products. Costs pile up from waste.

Laser cutting high-tenacity nylon fabric offers precision, speed, sealed edges, and low waste. It cuts production time by 40% and scrap by 20%, improving quality and efficiency.

I worked with a gear maker. Their hand-cut high-tenacity nylon fabric bags had 15% scrap. Lasers dropped it to 5%. Sales grew fast.

Precision leads. Lasers cut at 0.1mm accuracy, ideal for intricate designs like straps.

Speed Boost

Lasers cut at 70m/min, versus 20m/min for blades. This doubles output, freeing workers.

Sealed Edges

Edges seal instantly, preventing fraying. This eliminates extra finishing steps.

Waste Reduction

Waste falls to 5%. Manual methods hit 15%. This saves thousands yearly.

| Advantage | Manual Cutting | Laser Cutting |

|---|---|---|

| Precision | ±1mm | ±0.1mm |

| Speed | 20m/min | 70m/min |

| Waste | 15% | 5% |

| Edge Quality | Frayed | Sealed |

This table highlights wins. A client saw ROI in seven months. Safety improves—no blades, fewer injuries.

Lasers use 2kW, less than 5kW for mechanical cutters. It’s eco-friendly.

These benefits transform production. I’ve seen shops thrive with lasers.

What Are the Steps to Laser Cut High-tenacity Nylon Fabric?

Cutting high-tenacity nylon fabric seems simple. Its tough weave demands precision. Wrong steps cause burns or errors.

Laser cutting high-tenacity nylon fabric involves setting up the machine, uploading designs, adjusting power to 60-80W, cutting with air assist, and inspecting results for clean, sealed edges.

A client struggled with high-tenacity nylon fabric pouches. Their laser settings were off, causing burns. We walked through the process, and their cuts were perfect.

First, secure high-tenacity nylon fabric on a 900x600mm bed. Use RDWorks to upload designs. Set power to 60W for 1mm high-tenacity nylon fabric, 80W for 3mm.

Cutting Steps

Air assist at 20psi prevents burns. Cut at 70m/min for efficiency. Inspect edges for smoothness.

Post-Cut Check

Check for burns or fraying. Adjust power if needed. HEPA filters remove nylon fumes.

| Step | Action | Detail |

|---|---|---|

| Setup | Secure fabric | 900x600mm bed |

| Design | Upload file | RDWorks software |

| Power | 60-80W | Match thickness |

| Air Assist | 20psi | Prevent burns |

| Inspect | Check edges | Ensure no fraying |

This table outlines the process. Maintenance is easy—clean lenses every 500 hours.

For John, our purchasing manager, this ensures reliable output. Lasers streamline his supply chain.

These steps deliver clean high-tenacity nylon fabric cuts every time.

What Factors Influence Laser Cutting high-tenacity nylon fabric?

High-tenacity nylon fabric’s toughness varies. Wrong settings ruin cuts. Knowing key factors ensures success.

Factors influencing laser cutting high-tenacity nylon fabric include material thickness, laser power, speed, air assist, and ventilation. Proper settings prevent burns and ensure clean, sealed edges.

I helped a tent maker with 1000D high-tenacity nylon fabric. High power burned it. Adjusting settings fixed everything.Thickness is critical. Most high-tenacity nylon fabric is 1-3mm. Thicker needs multi-pass cuts at 80W.

Laser Power and Speed

Power ranges from 60-80W. Speed at 70m/min balances quality and efficiency. Too fast causes skips.

Air and Ventilation

Air assist at 20psi cools cuts. HEPA ventilation removes toxic nylon fumes for safety.

| Factor | Impact | Optimal Setting |

|---|---|---|

| Thickness | Cut depth | 1-3mm, multi-pass for thicker |

| Power | Cut quality | 60-80W |

| Speed | Efficiency | 70m/min |

| Air Assist | Burn prevention | 20psi |

| Ventilation | Safety | HEPA filter |

This table shows key factors. Testing samples prevents errors. I always run 10cm tests.

For John, these factors ensure consistent quality. He sources high-tenacity nylon fabric from trusted mills.

Master these, and your cuts will be flawless.

What Are General Tips for Laser Cutting high-tenacity nylon fabric?

Laser cutting high-tenacity nylon fabric can trip you up. Burns or fumes slow production. Tips save time.

Tips for laser cutting high-tenacity nylon fabric: use 60-80W power, 20psi air assist, test samples, ensure HEPA ventilation, and clean lenses monthly for consistent, clean cuts.

A client’s high-tenacity nylon fabric cuts scorched. We lowered power and added air assist. Results were perfect in an hour.

Set power to 60W for 1mm, 80W for 3mm. Test samples first to avoid waste.

Ventilation and Maintenance

HEPA filters are a must for fumes. Clean lenses monthly to maintain beam focus.

| Tip | Purpose | Detail |

|---|---|---|

| Power | Clean cuts | 60-80W, test first |

| Air Assist | Prevent burns | 20psi |

| Samples | Avoid errors | 10cm tests |

| Ventilation | Safety | HEPA filters |

| Maintenance | Beam focus | Clean lenses monthly |

This table lists tips. CAD software speeds design uploads, saving 50% setup time.

For John, these tips mean reliable machines. His suppliers value consistency.

These tips keep your high-tenacity nylon fabric cuts smooth and efficient.

What Are Common FAQs About Laser Cutting high-tenacity nylon fabric?

High-tenacity nylon fabric cutting raises questions. People worry about burns, safety, and costs. Clear answers help.

Common FAQs: Can lasers cut thick high-tenacity nylon fabric? Are fumes safe? CO2 lasers cut up to 3mm, are safe with ventilation, and save 20% on waste.

A skeptical client thought lasers were risky. A demo showed clean cuts and safe air. They bought two machines.

Can lasers cut thick high-tenacity nylon fabric? Yes, up to 3mm with 80W. Multi-pass for thicker.

Safety Concerns

Fumes need HEPA filters. They capture 99% of nylon particles, meeting OSHA standards.

| Question | Answer | Detail |

|---|---|---|

| Max thickness? | 3mm | Multi-pass for thicker |

| Safe fumes? | Yes, with HEPA | 99% particle capture |

| Cost-effective? | Yes | 20% waste reduction |

| Material types? | 500-1000D | Clean cuts |

This table addresses concerns. Lasers save 20% on scrap. ROI hits in 8 months.

Training is quick—a day with our videos. Maintenance is low, just monthly lens cleaning.

For John, these answers ease procurement. He prioritizes safety and cost.

These FAQs make lasers a practical choice for high-tenacity nylon fabric.

Which Machine Is Best for Laser Cutting high-tenacity nylon fabric?

Picking a machine feels overwhelming. Specs confuse. A bad choice wastes money.

I recommend the Redshift RL-1000 CO2 Laser Cutting Machine. It has 80W power, 1000mm width, auto-feed, and HEPA ventilation, perfect for high-tenacity nylon fabric up to 3mm.

John pushed for a reliable high-tenacity nylon fabric cutter. The RL-1000 delivers with consistent performance.

Its 80W CO2 laser cuts 3mm high-tenacity nylon fabric at 70m/min. Auto-feed ensures smooth fabric flow.

Key Features

The CCD camera aligns cuts at 0.05mm precision. HEPA filters keep air safe.

| Feature | RL-1000 Spec | Why It Matters |

|---|---|---|

| Power | 80W CO21 | Cuts 3mm at 70m/min |

| Width | 1000mm | Fits high-tenacity nylon fabric rolls |

| Alignment | CCD Camera2 | 0.05mm precision |

| Ventilation | HEPA Filter | Safe air |

| Warranty | 2 Years | Reliable support |

This table sums it up. The RL-1000 is user-friendly with RDWorks software.

Priced for mid-size shops, it saves 20% on waste. ROI in 9 months.

We offer demos. Test high-tenacity nylon fabric samples. Our US and China teams support setup.

For John, it balances cost and quality. Ethical parts ensure sustainability.

Choose the RL-1000 for top high-tenacity nylon fabric cuts.

Conclusion

Laser cutting high-tenacity nylon fabric delivers precision, speed, and sealed edges. From gear to bags, it boosts efficiency. Master it for durable, high-quality products.