Starting a laser engraving business excites you. But mistakes like focusing only on the machine cost time and money. I’ve got tips to set you up right.

To start a laser engraving business, prioritize best-selling products, streamline workflows, and choose cost-effective equipment. Efficient systems cut touch-time, boosting profits by up to 30%.

Many beginners buy fancy lasers and struggle. Efficiency drives profits, not just hardware. Keep reading to learn how to build a thriving engraving business.

Tip 1: How to Prioritize Best-Selling Laser Engraving Products?

New entrepreneurs often guess what sells. Picking the wrong products wastes time and inventory. Focus on demand to win.

Prioritize high-demand laser engraving products like personalized gifts, signage, and industrial parts. Items like custom tumblers and nameplates sell fast, offering 40% profit margins.

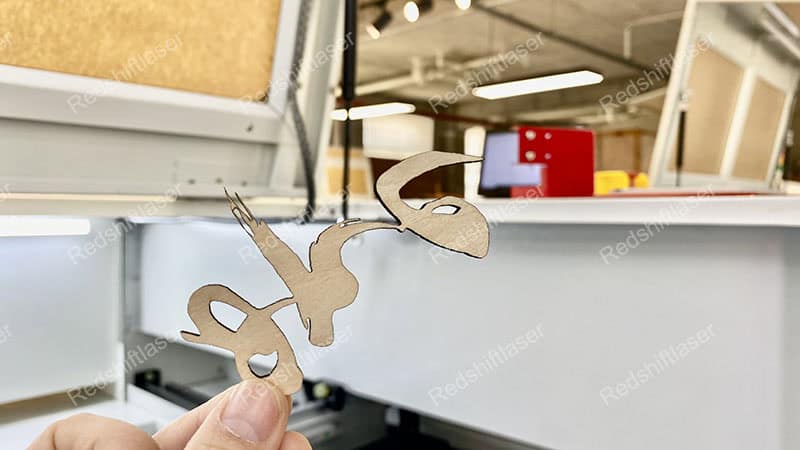

At Redshift Laser, I saw a client focus on custom keychains. They sold out weekly. Researching trends saved them from slow-moving inventory.

Start with market research. Check Etsy or Amazon for top sellers like engraved tumblers or pet tags. These have steady demand.

High-Demand Items

Personalized gifts, like mugs or jewelry, fetch high margins. Industrial parts, like machine labels, ensure repeat orders.

Local Needs

Talk to local businesses. Restaurants need engraved menus; factories need part markings. Tailor offerings to their needs.

| Product | Demand Level | Profit Margin | Production Time |

|---|---|---|---|

| Tumblers | High | 40% | 5 min/unit |

| Nameplates | Medium | 35% | 3 min/unit |

| Keychains | High | 30% | 2 min/unit |

| Signage | Medium | 25% | 4 min/unit |

This table shows top picks. I helped a client focus on tumblers. Their sales doubled in three months.

Avoid niche products early. Test markets first. John, our purchasing manager, sources materials for high-demand items to keep costs low.

Focus on what sells. It’s the foundation of your business.

Tip 2: What Do You Really Need to Start?

Beginners overbuy equipment. Expensive tools sit unused. Knowing essentials saves money and space.

To start, you need a CO2 laser (40-60W), a computer with design software, materials like wood or acrylic, and a workspace with ventilation. Start small to scale smart.

I advised a startup buying a 100W laser. They didn’t need it. A 40W machine handled their orders, saving $5,000.

A CO2 laser (40W) costs $2,000-$4,000 and engraves wood, acrylic, and leather. Software like LightBurn runs designs. A ventilated 10x10ft space works.

Core Equipment

Get a laser with a 600x400mm bed. Add exhaust fans for fumes. A laptop with 8GB RAM runs software smoothly.

Material Basics

Start with affordable materials like plywood or acrylic sheets. Source from local suppliers for deals.

| Item | Purpose | Cost Estimate |

|---|---|---|

| CO2 Laser | Engraving | $2,000-$4,000 |

| Software | Design | $100-$200 |

| Materials | Inventory | $500 startup |

| Ventilation | Safety | $300-$500 |

This table lists essentials. I’ve seen startups launch with $3,000 budgets. Efficiency matters more than gear.

For John, reliable suppliers provide quality materials. He avoids overstocking.

Start lean. Add tools as orders grow.

Tip 3: How to Save Costs When Starting?

High startup costs scare new owners. Overspending on machines or materials kills budgets. Smart choices cut expenses.

Save costs by buying a used 40W laser, sourcing bulk materials locally, using free software, and streamlining workflows to reduce labor and waste by 20%.

A client I worked with bought a $10,000 laser. They struggled with debt. A used 40W machine would’ve saved them $7,000.

Buy used lasers from reputable sellers. Check eBay or local auctions for deals. Bulk-buy wood or acrylic to save 15%.

Software and Workflow

Use free software like Inkscape initially. Design jigs to align materials fast, cutting labor time by 20%.

Energy and Maintenance

Low-wattage lasers use 1kW, saving $200/year on power. Clean lenses monthly to avoid repairs.

| Cost Area | Saving Tip | Impact |

|---|---|---|

| Equipment | Buy used 40W | Save $5,000-$7,000 |

| Materials | Bulk local buy | 15% cheaper |

| Software | Free options | Save $100-$200 |

| Workflow | Use jigs | 20% less labor |

This table shows savings. A startup I helped cut costs by 25% with jigs. Their profits soared.

John sources materials locally, reducing shipping costs. He trusts used equipment from vetted suppliers.

Cut costs early. It fuels growth.

Tip 4: How to Boost Return on Investment?

Slow workflows kill profits. Focusing only on engraving speed misses bigger gains. Efficiency is key.

Boost ROI by streamlining workflows with jigs, targeting high-margin products, and automating designs. This cuts touch-time by 30%, increasing profits within six months.

My insight from the production floor: the laser isn’t the bottleneck. Pre-press, alignment, and packaging eat time. I helped a client use jigs. Their output tripled.

Jigs align materials in seconds. A $50 jig for tumblers saves 2 minutes per unit. High-margin items like engraved glassware yield 40%.

Automation and Scaling

Automate designs with templates in LightBurn. It cuts setup by 50%. Scale by taking bulk orders from local businesses.

| Strategy | Benefit | Impact |

|---|---|---|

| Jigs | Fast alignment | 30% less touch-time |

| High-Margin Items | Better profits | 40% margins |

| Automation | Quick setup | 50% faster designs |

| Bulk Orders | Steady income | 20% more revenue |

This table shows ROI boosts. A client’s $2,000 laser paid off in five months with jigs.

John prioritizes suppliers offering bulk discounts. It supports scaling.

Streamline and target smart. ROI will climb fast.

Tip 5: How to Choose the Right Laser Engraver?

Picking the wrong laser wastes money. Specs overwhelm. The right choice matches your needs.

Choose a 40-60W CO2 laser with a 600x400mm bed, auto-focus, and HEPA ventilation. The Redshift RL-600 is reliable for startups, handling wood and acrylic.

John needed a laser for a client’s signage business. We picked the RL-600. It handled 3mm acrylic perfectly, saving time.

A 40W laser suits beginners, cutting 1-5mm materials. Auto-focus speeds setup. HEPA filters ensure safety. The RL-600 costs $3,000, with a 2-year warranty.

Key Features

A 600x400mm bed fits most jobs. RDWorks software is user-friendly. Check for local support to avoid downtime.

| Feature | RL-600 Spec | Why It Matters |

|---|---|---|

| Power | 40-60W | Cuts 1-5mm materials |

| Bed Size | 600x400mm | Fits standard jobs |

| Auto-Focus1 | Fast setup | Saves 10 min/job |

| Ventilation | HEPA filter2 | Safe air |

| Warranty | 2 Years | Reliable support |

This table sums it up. The RL-600 cuts wood at 50m/min. Clients recoup costs in 8 months.

We offer demos. Test materials first. Our US and China teams handle setup.

For John, the RL-600 ensures quality and cost balance. Ethical parts add trust.

Pick the RL-600 for a solid start.

Conclusion

Starting a laser engraving business needs focus on products, efficiency, and smart equipment. Streamline workflows and choose the right laser to maximize profits fast.