You are constantly replacing blades, shears, or expensive dies for cutting sandpaper. The abrasive grit dulls even the sharpest steel tools at an incredible rate, leading to high maintenance costs, production downtime, and frustratingly inconsistent cuts. You're fighting a battle against tool wear, but the real cost is a combination of constant replacement expenses and the frayed, inefficient edges you're producing.

The best way to cut sandpaper, especially at an industrial scale, is with a non-contact CO2 laser cutter. A laser vaporizes the material instead of physically shearing it, meaning there are no blades to dull or replace. This process completely avoids mechanical stress, resulting in a perfectly clean, precise edge that doesn't suffer from micro-fractures or grit loss, an issue that plagues all mechanical cutting methods.

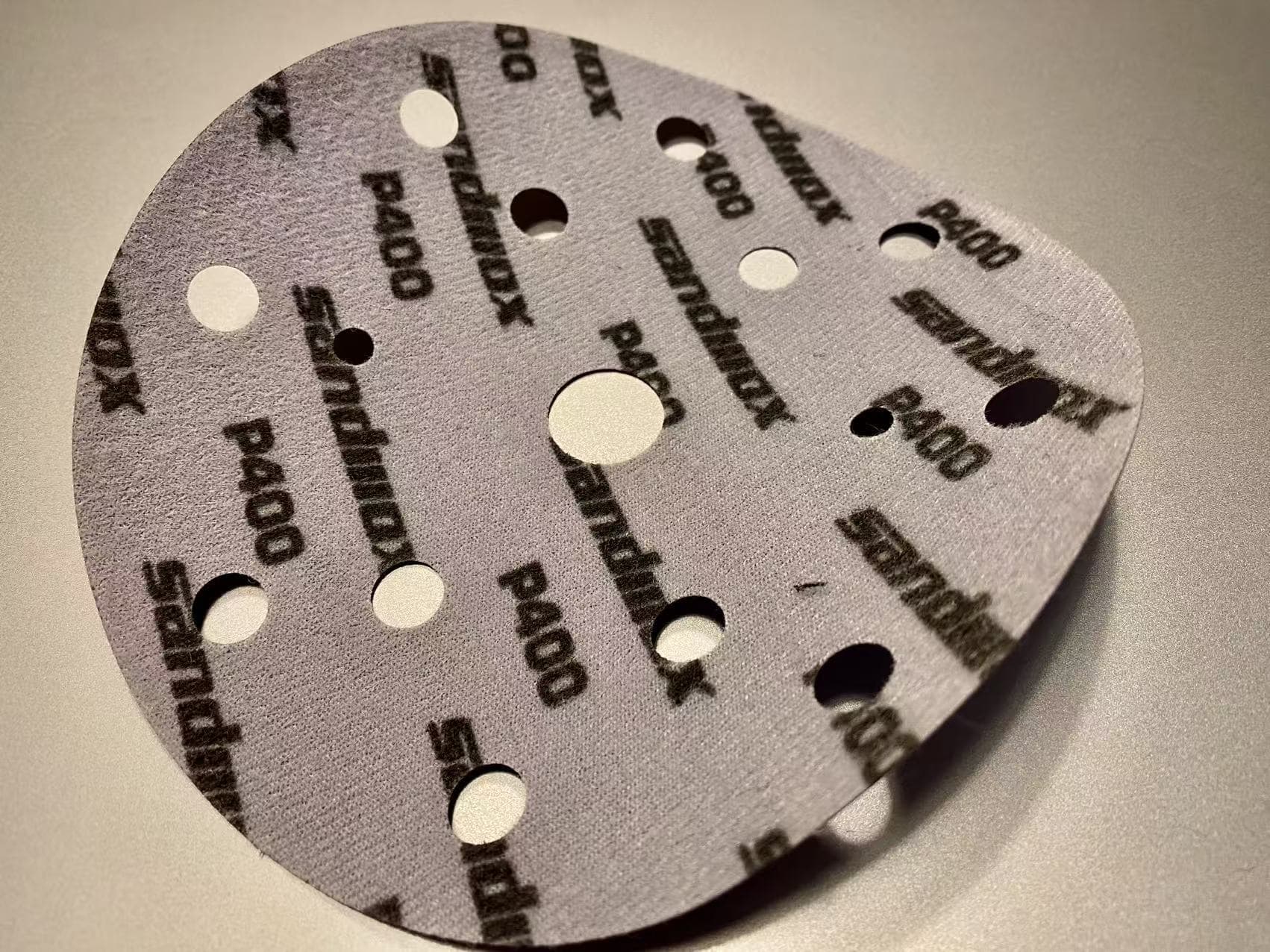

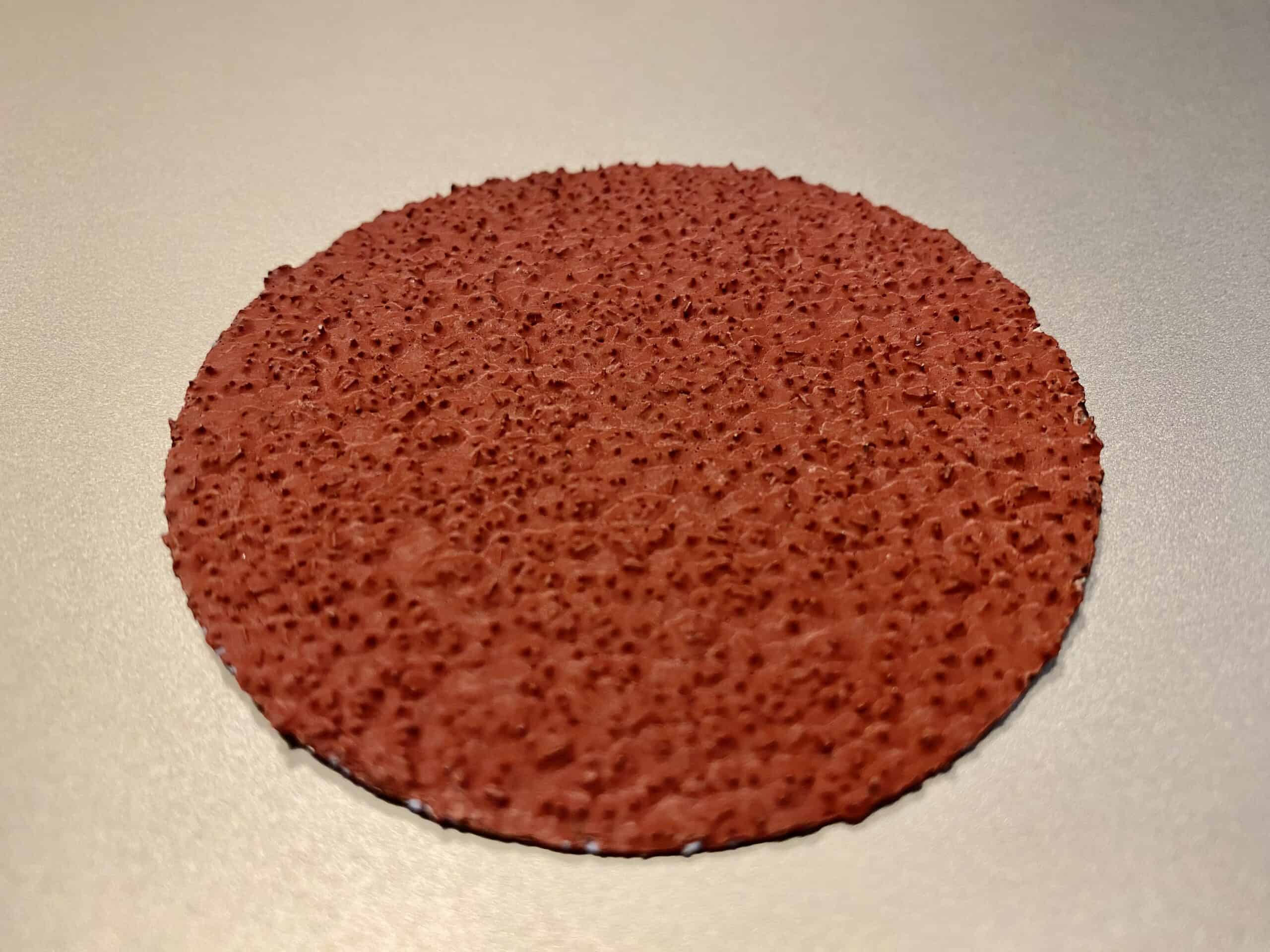

This reminds me of a client who manufactured sanding discs for the automotive industry. They were spending a small fortune on sharpening and replacing their steel rule dies. They called me in to discuss a laser as a way to cut maintenance costs. During our visit, I took one of their die-cut discs and one we cut on a laser and looked at them under a digital microscope. The die-cut edge was visibly fractured, with grit particles dislodged. They realized their biggest problem wasn't the cost of the dies; it was that they were shipping a product that was already compromised before it even left their factory.

What are the Different Types of Sandpaper?

You know there are different sandpapers, but do you know how their composition affects the cutting process? Choosing the wrong cutting method for a specific a backing or grit type can lead to poor results, like torn paper backing or melted plastic films. This can compromise the quality of your final product and cause unnecessary waste.

Sandpaper is categorized by its two main components: the abrasive grit (like aluminum oxide or silicon carbide) and the backing material (paper, cloth, film, or fiber). Both of these components directly impact how the material should be cut. A CO2 laser is highly effective because it can cleanly vaporize both the abrasive minerals and the various backing materials with equal precision.

Understanding the Components

For an industrial buyer, knowing the material composition is key to selecting the right processing technology. Let's break down the two critical parts of sandpaper.

1. Abrasive Grit Material

The "sand" in sandpaper isn't sand at all. It's typically a much harder mineral. The most common types include Aluminum Oxide (a tough, durable all-rounder), Silicon Carbide (very sharp, ideal for harder materials), and Ceramic Alumina (extremely hard and self-sharpening). From a cutting perspective, these minerals are what destroy mechanical blades. For a laser, however, they are simply material to be vaporized.

2. Backing Material

The backing holds the grit and provides flexibility. Paper is common but can tear easily with mechanical cutters. Cloth backings (like cotton or polyester) are more durable but can fray when cut with a dull blade. Film backings offer a very smooth finish but can melt or gum up a blade. A laser cutter is agnostic to these issues, cutting each material cleanly without physical contact.

3. The Bonding Agent

A layer of adhesive holds the grit to the backing. Mechanical cutting places immense shear force on this bond, which is what causes the micro-fractures and grit loss. Since a laser uses thermal energy, it removes the grit and backing together without stressing this crucial adhesive bond.

What Are the Common Ways to Cut Sandpaper?

You're using traditional tools like utility knives or die cutters to shape sandpaper. But you're dealing with the consequences every single day: blades that are sharp one minute and useless the next, slow cutting speeds, and jagged edges that affect product performance. You feel stuck with inefficient methods because it's what has always been done.

The most common sandpaper cutters are utility knives for manual work, and steel rule die cutters for industrial production. While widely used, both methods rely on mechanical force, which leads to rapid tool dulling and, more importantly, damages the sandpaper's edge by dislodging abrasive grit. A CO2 laser represents a modern, non-contact alternative that solves both of these fundamental problems.

Comparing Cutting Methods

When choosing a cutting method, you're making a trade-off between speed, cost, and quality. For John and other purchasing managers, understanding the long-term impact on quality and operational cost is crucial.

1. Manual Cutting (Knives & Scissors)

This is fine for one-off jobs in a workshop but completely impractical for production. Blades dull almost instantly, cuts are imprecise, and it's incredibly slow. It's a method born of necessity, not efficiency.

2. Die Cutting

This is the traditional industrial method. A hydraulic press pushes a sharp steel die through sheets of sandpaper. It's fast, but the high-impact process accelerates blade dulling and, critically, fractures the abrasive edge, causing grit to flake off. Tooling is expensive, and you are limited to a single shape per die.

3. Laser Cutting

This method uses a focused beam of light to vaporize the sandpaper. It's a non-contact process, which means no tools to wear out. More importantly, it avoids all mechanical stress on the material. The laser cuts a perfect, clean edge that retains 100% of its grit integrity, leading to a higher-performing end product.

Cutting Method Comparison Table

| Feature | Utility Knife | Steel Rule Die Cutter | CO2 Laser Cutter |

|---|---|---|---|

| Tool Wear | Extremely High | Very High | None |

| Edge Quality | Poor (Jagged) | Fair (Micro-fractures) | Excellent (Clean-sealed) |

| Grit Loss | High | High | Near-Zero |

| Precision | Low | Good | Excellent |

| Shape Complexity | Very Low | Low (Fixed by Die) | Unlimited |

| Setup Cost | Negligible | Very High (Die Cost) | Medium (Machine Cost) |

How Do You Choose the Right Sandpaper Cutter?

You need to invest in a cutting solution, but the options seem overwhelming. How do you decide between a familiar mechanical process and a newer technology like a laser? Making the wrong choice could mean getting stuck with the same old problems of high maintenance and poor quality, or investing in a machine that doesn't fit your production needs.

To choose the right sandpaper cutter, you must evaluate three key factors: production volume, required shape complexity, and desired final product quality. For low-volume or simple shapes, a die cutter might seem adequate. However, for high-volume, high-precision manufacturing that requires flexible shapes and superior edge integrity, a CO2 laser cutter is the clear choice for a better product and lower operational cost.

Decision-Making Criteria

As a purchasing manager, your decision needs to be backed by data and a clear understanding of the operational impact. Here are the factors to consider.

1. Evaluate your Production Volume

How many pieces do you cut per day? For a handful of items, manual cutting is tedious but possible. For thousands of sanding discs, you need an automated solution. Both die cutters and laser cutters offer high throughput, but the laser wins on uptime due to the lack of tool changes and maintenance.

2. Consider Shape Complexity and Flexibility

Are you cutting simple circles and squares, or do you need to produce custom shapes for specialized tools? A die cutter locks you into a single shape. If a client needs a new design, you have to order a new, expensive die and wait for it to be made. With a laser, you can switch from cutting a 5-inch disc to a detailed triangular pad by simply loading a new design file.

3. Prioritize Final Product Quality

This is the most critical point, based on my insight. Do you want to sell a product that is simply "cut to shape," or one that is cut for maximum performance? Mechanical methods inherently damage the product they are creating. A laser is the only method that preserves the integrity of the abrasive bond right to the edge, delivering a genuinely superior product to your customers.

What Are the Applications of Laser Cut Sandpaper?

You understand that a laser can cut sandpaper, but where is this technology actually being used? Without seeing real-world applications, it's hard to visualize how it fits into your own production line or what new opportunities it might open up. You need to see the practical, valuable uses for this level of precision.

Laser cut sandpaper is primarily used in manufacturing high-performance abrasive products where precision and edge integrity are critical. Key applications include producing sanding discs for orbital sanders (with perfect dust extraction holes), custom-shaped abrasive pads for robotics and automated finishing systems, and detailed abrasive sheets for specialized manual tools used in woodworking, automotive, and aerospace industries.

Where Precision Makes a Difference

The demand for laser-cut abrasives is growing in industries where performance standards are high.

1. Orbital Sanding Discs

Modern orbital sanders use complex, multi-hole patterns for dust extraction. A laser can cut these intricate patterns perfectly every time. A die cutter struggles with this, often tearing the paper between closely spaced holes, and the dies for these patterns are incredibly complex and expensive.

2. Automated & Robotic Sanding

As manufacturing becomes more automated, robots are used for finishing surfaces. These systems require abrasive pads cut to exact and often unique specifications to match the robotic end-effector. A laser provides the precision and repeatability that these high-tech applications demand.

3. Specialty Abrasives

Think about the detailed sanding pads1 used in auto body repair or for finishing fine furniture. These often have non-standard shapes designed to fit into tight corners or follow specific contours. Laser cutting allows for the cost-effective production of these niche, high-margin products without the need for custom tooling.

Conclusion

When we talk about cutting sandpaper, the conversation often gets stuck on the problem of dull blades. But as we've seen, that's only a surface-level issue. The real challenge is the damage that mechanical cutting does to the sandpaper itself, causing micro-fractures and grit loss that reduce performance. A CO2 laser cutter solves both problems at once. By using a non-contact thermal process, it eliminates tool wear entirely while producing a perfect, clean edge that preserves the abrasive integrity. This isn't just a better way to cut; it’s a way to make a better final product.

FAQ: Laser Cutting Sandpaper

Q1: Will the laser burn the paper backing on the sandpaper?

A: No, it won't. This is a common concern. A CO2 laser works by vaporizing the material so quickly that there is no time for heat to spread and cause charring or burning. The process is one of rapid ablation, leaving a clean, sealed edge on paper, cloth, or film backings without any fire risk or discoloration.

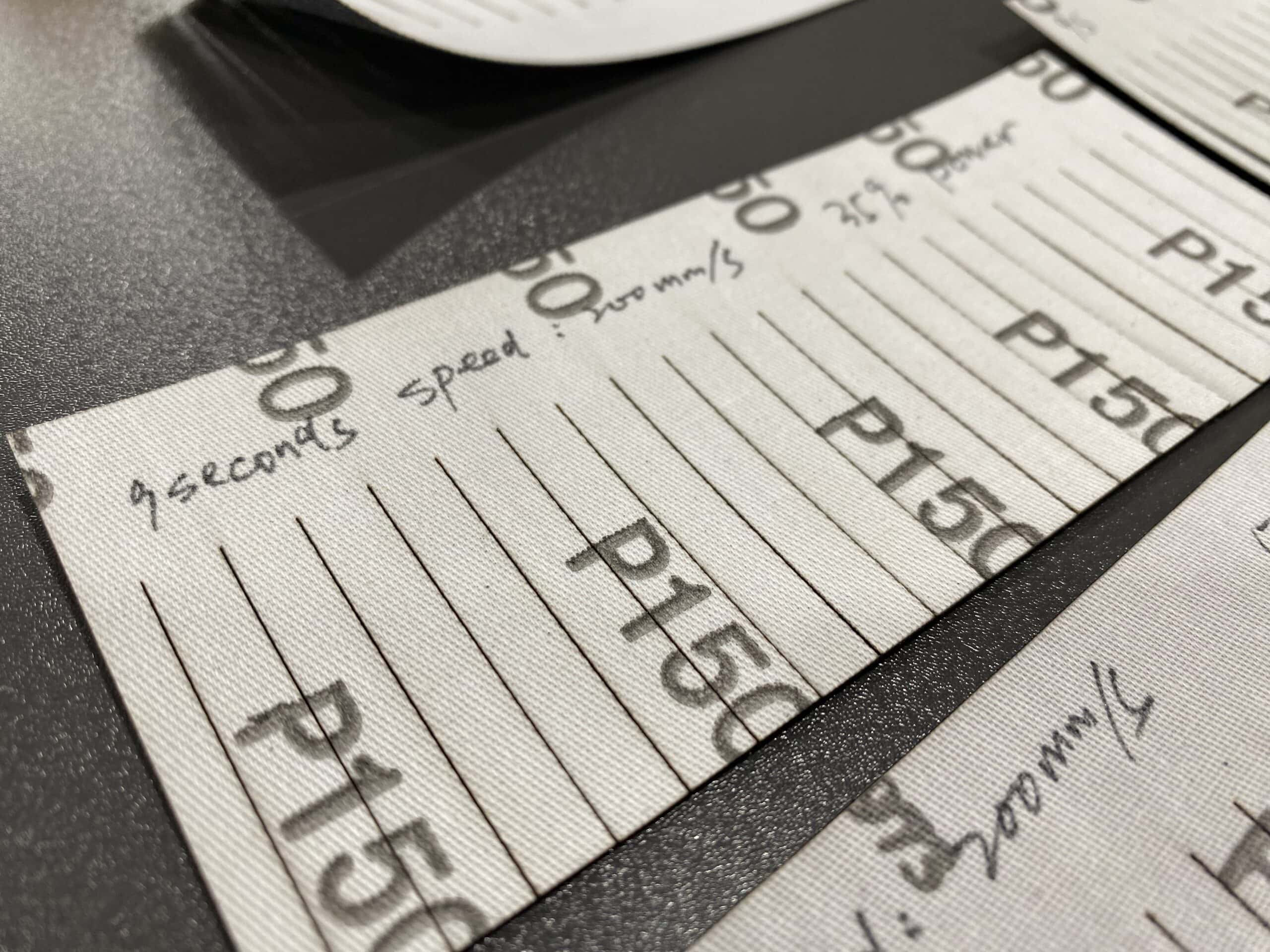

Q2: What laser power is needed for cutting sandpaper?

A: You don't need a very high-powered laser. For most sandpaper types, a CO2 laser with a power of 80-100W is more than sufficient. This provides the perfect balance of cutting speed for industrial throughput and the control needed for fine details, like dust extraction holes, without overpowering the material.

Q3: Does laser cutting sandpaper create a lot of harmful dust or fumes?

A: The laser vaporizes the abrasive grit, bonding agents, and backing material, which does create fumes. Therefore, a proper fume extraction and filtration system is absolutely essential. This is a standard part of any industrial laser installation and ensures a safe operating environment by removing all airborne particles and odors at the source.

Q4: How does the operational cost of a laser compare to a die cutter over time?

A: While the initial investment in a laser cutter is higher, the long-term operational cost is significantly lower. With a die cutter, you have continuous costs for sharpening, repairing, and replacing dies, plus production downtime for these changes. The laser has no consumable tooling. Its main operational costs are electricity and periodic maintenance, making the Total Cost of Ownership much more favorable over time.

Q5: Can a laser cut through very coarse grit sandpaper, like 36 or 40 grit?

A: Yes, very effectively. In fact, coarse grits are where the laser's advantages are most obvious. These heavy-duty grits destroy mechanical blades at an extremely high rate. For a laser, cutting 40-grit sandpaper is no more difficult than cutting 220-grit. The laser's power can be adjusted to cut cleanly through any grit size and backing combination without any wear and tear.

Relate

-

Explore this link to understand the unique applications and benefits of detailed sanding pads in various repair processes. ↩