Worried about choosing the wrong CO2 laser for your packaging business? A cheap machine can seem like a good deal but often leads to high operating costs and limits your growth.

To choose the right CO2 laser, evaluate its work area, power, and cooling system against your materials (e.g., paperboard, corrugated). Prioritize software, support, and total cost of ownership—not just purchase price—to ensure a profitable, long-term investment that meets market demands.

I've seen many packaging businesses evaluate lasers. The most common mistake is focusing only on the sticker price. They treat it like buying a simple tool, but it's much more than that. Investing in a CO2 laser is a strategic decision about where your business is heading. The right machine doesn't just cut costs; it opens up new markets for custom, high-margin work. Let's break down how to make the right choice.

What to Know Before Buying a CO2 Laser Machine?

You're ready to invest, but the technical specifications are overwhelming. How do you know what laser power or bed size you actually need, and what hidden factors could cause problems later?

Before buying, you must identify your primary materials (paper, cardboard), required bed size for your largest products, and necessary laser power (wattage) for your desired cutting speed and thickness. Also, verify software compatibility and the provider's technical support.

I always tell clients to start with their products, not the machine. Your materials and production needs will dictate the right specifications. A machine that's perfect for a sign shop might be completely wrong for a packaging manufacturer. Don't let a salesperson push a generic solution on you.

Your Pre-Purchase Checklist

You need to answer these questions before you can meaningfully compare different models.

- What materials will you cut? Paper, paperboard, and corrugated cardboard all react differently. The laser must be optimized for these.

- What is your working size? The laser's bed size must accommodate your largest standard sheet or product. Buying a bed that's too small is a critical error, while buying one that's too big wastes money and floor space.

- What laser power do you need? Power (measured in watts) determines cutting speed and thickness.

- Low Power (40-60W): Good for scoring, engraving, and cutting thin paper or cardstock.

- Mid Power (80-100W): A versatile choice for most packaging, able to cut paperboard and thin corrugated cardboard efficiently.

- High Power (130W+): Necessary for cutting thick, multi-layered corrugated material at high production speeds.

- What software does it use? Ensure the machine’s control software is user-friendly and compatible with your existing design programs (like Adobe Illustrator or CAD). Poor software can become a daily frustration.

How are CO₂ Lasers Being Used in the Packaging Industry to Improve Efficiency?

Are slow, expensive die-cutting setups killing your efficiency on short runs? The time and cost to create physical dies make it nearly impossible to quickly respond to client requests for samples or custom orders.

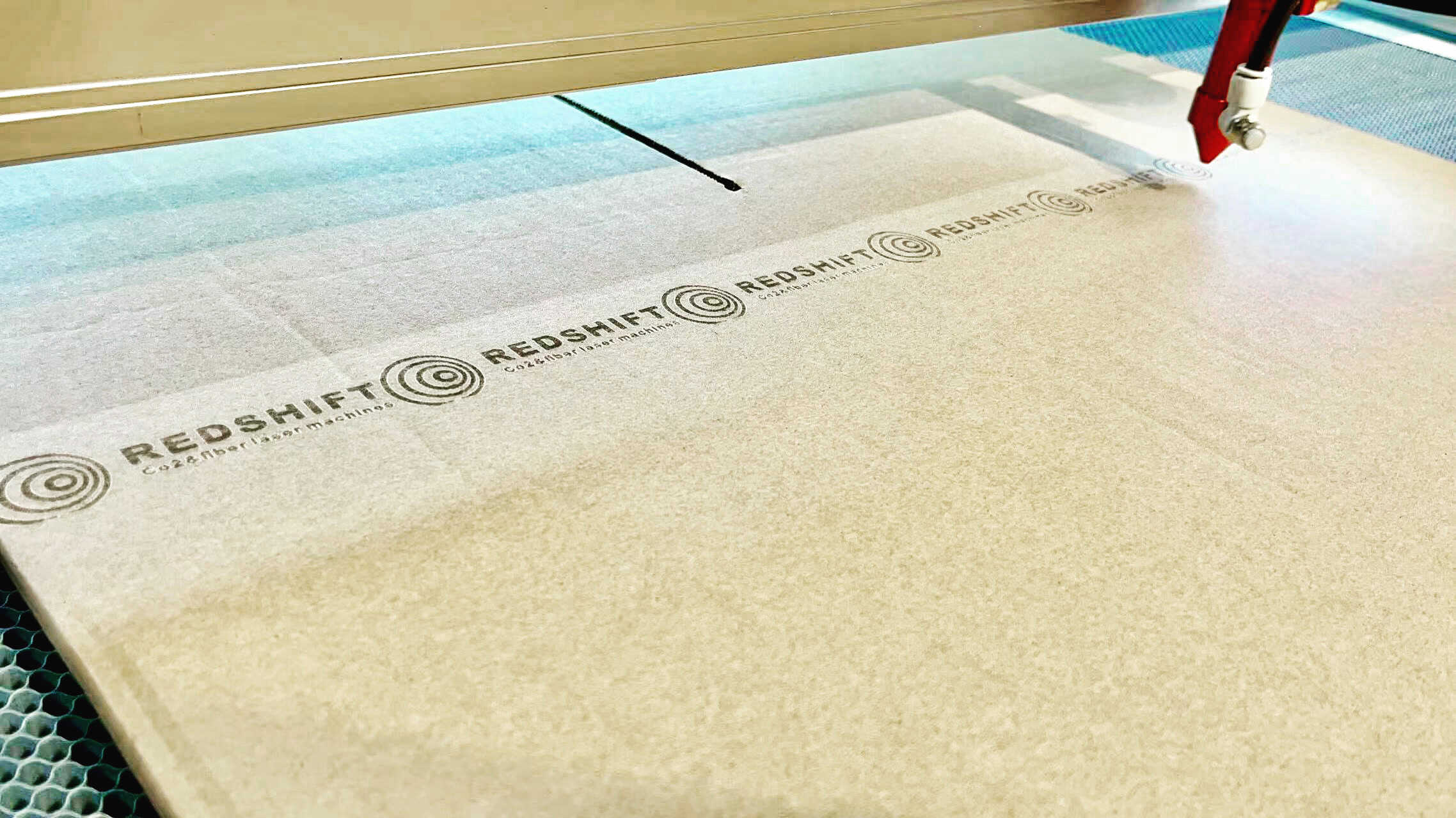

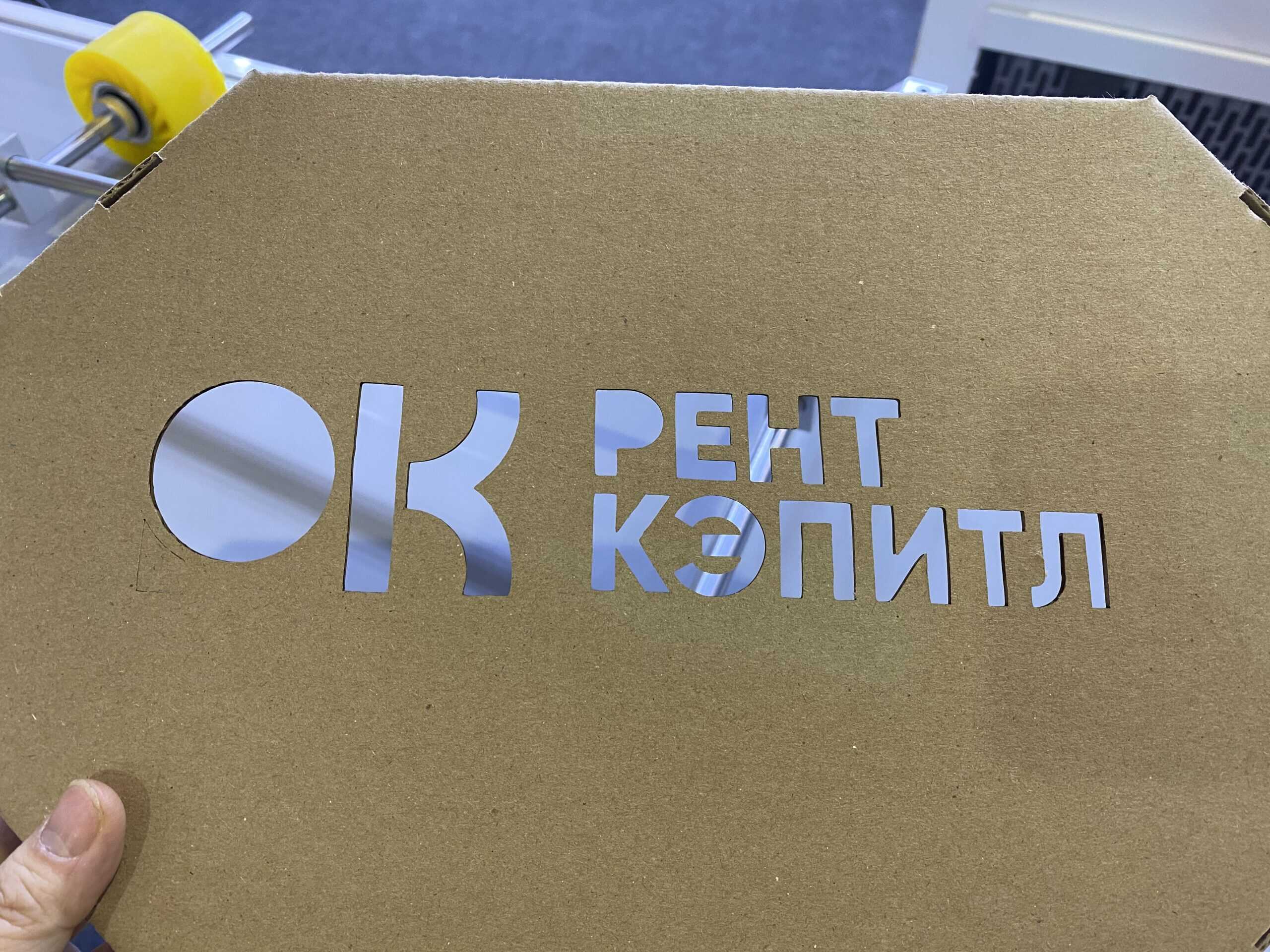

CO₂ lasers improve efficiency by enabling "die-less" cutting. This eliminates the time and cost of die production, allowing for instant changeovers between jobs, rapid prototyping, and automated cutting directly from a digital file.

In the packaging world, speed and flexibility are the new currency. The market is shifting away from massive, identical production runs toward shorter, more customized orders. I've watched companies with traditional die presses struggle to keep up. They can't profitably produce 50 custom boxes for an event. A business with a laser can. This is the core efficiency gain: the ability to say "yes" to any job, any size, any time.

The Efficiency Trifecta: Speed, Flexibility, and Automation

- Rapid Prototyping: A client requests a new box design. With a laser, your designer can create a digital file and produce a perfect physical prototype in minutes. With die-cutting, this would take days or weeks and cost thousands. This speed allows for faster client approval and gets you into production sooner.

- Instant Changeover: Switching from one box design to another is as simple as loading a new digital file. There is no downtime for changing heavy, mechanical dies. This "zero-setup" capability means you can run dozens of different small jobs in a single day, maximizing machine uptime and profitability.

- Reduced Material Waste: Advanced nesting software automatically arranges shapes on the material to minimize waste. The laser's precise cut, with its very small kerf (the width of the cut), allows for tighter nesting than is possible with a physical die, saving you money on every sheet.

How Much Does It Cost to Run a CO2 Laser Machine?

You see the benefits, but you're worried about hidden running costs. Can electricity, replacement parts, and maintenance turn an affordable machine into a long-term financial drain?

The primary running costs for a CO2 laser are electricity, replacing the laser tube every 2-5 years, and routine maintenance like cleaning lenses. On average, total operating costs are significantly lower than the ongoing expense of manufacturing new dies for traditional cutting.

This is a fair question, and one every smart manager should ask. When I help businesses calculate the Total Cost of Ownership (TCO), we look far beyond the purchase price. The good news is that for packaging applications, the TCO of a laser is often surprisingly low, especially when compared to the alternative.

Breakdown of Ongoing Costs

| Cost Component | Details | Typical Frequency/Cost |

|---|---|---|

| Electricity | The machine and its chiller consume power. The cost depends on your local rates and how many hours you run the machine. | Varies, but generally a manageable operational expense for an industrial machine. |

| Laser Tube | This is the main consumable. It's a glass tube with a finite lifespan, measured in operating hours. | Replace every 3,000-10,000 hours (2-5 years of single-shift use). Cost: $1,000 - $5,000+. |

| Optics | Mirrors and the focusing lens need regular cleaning. They can degrade or get damaged over time and need replacement. | Clean daily/weekly. Replace every 1-3 years if well-maintained. Cost: $100 - $500 per set. |

| Routine Maintenance | Includes things like distilled water for the chiller and lubrication for mechanical parts. | Low cost, done as needed. |

When you add this up and compare it to the tens of thousands you might spend on new dies each year, the laser often pays for itself through these savings alone.

What is the Future of CO2 Laser Technology for Manufacturing?

Is this technology just a trend, or is it a fundamental shift in manufacturing? You need to ensure that an investment made today will remain relevant and competitive for years to come.

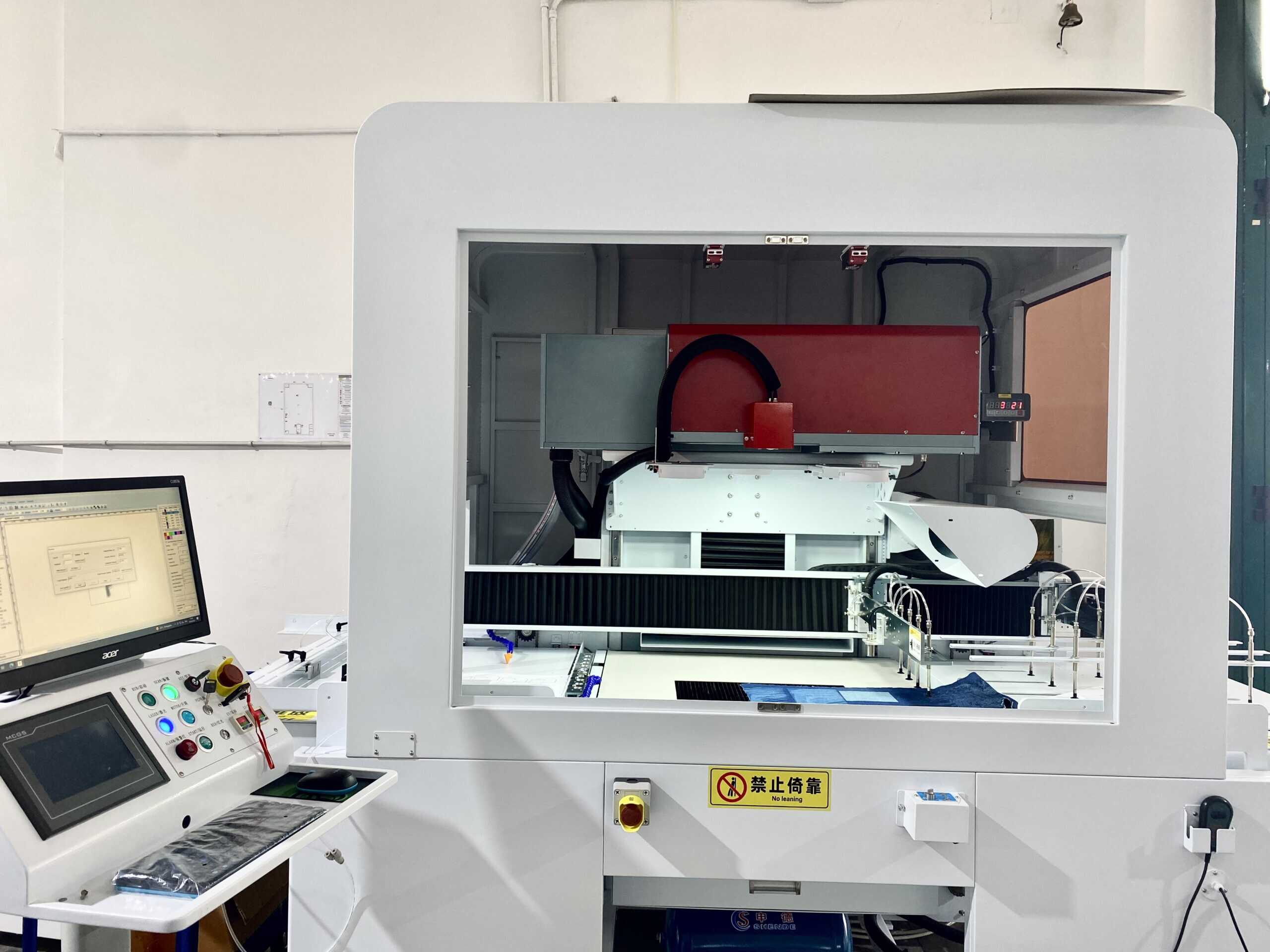

The future of CO2 laser technology is in its integration with automation and smart software. Expect to see fully automated systems that handle material loading, cutting, and unloading, all driven by AI that optimizes cutting paths and predictive maintenance.

From my position in the industry, I can tell you that we are only at the beginning of the laser revolution in manufacturing. The machines are becoming faster, smarter, and more accessible every year. The move is towards complete "lights-out" manufacturing, where entire production lines run with minimal human intervention.

Key Future Trends

- Full Automation: The next generation of systems will integrate robotic arms to load raw sheets onto the laser bed and unload the finished, cut parts. This will enable 24/7 production with minimal labor.

- AI-Powered Software1: Software will move beyond simple nesting. AI will analyze designs in real-time to find the absolute most efficient cutting path, adjust laser parameters on the fly based on material variations, and even predict when a component (like a laser tube) is nearing the end of its life to prevent unplanned downtime.

- Increased Speed and Power2: Laser source technology continues to improve, promising even faster cutting speeds. This will further close the gap with traditional die-cutting on even the longest production runs, making lasers the go-to choice for almost any job.

Investing in a CO2 laser3 now is not about catching up; it's about positioning your business for this more efficient and automated future4.

Conclusion

Choosing the right CO2 laser is about aligning the technology with your business strategy. Focus on total value and future flexibility, not just the initial price, to build a more competitive business.

Related:

-

Explore how AI-Powered Software can revolutionize manufacturing efficiency and reduce downtime. ↩

-

Learn about the advancements in laser technology that enhance production speed and efficiency. ↩

-

Explore this link to understand how a CO2 laser can enhance efficiency and automation in your business. ↩

-

Discover insights on how automation is transforming business landscapes and why you should adapt. ↩