Felt cutting by hand is slow and messy. Errors waste material. I found a method that ensures precision and creativity.

Laser cutting felt uses a focused beam to create precise, sealed edges. It boosts efficiency by 50% and reduces waste by 25%, delivering flawless felt products.

Manual tools struggle with felt’s texture. They cause fraying and delays. Laser cutting solves these issues. Keep reading to explore how it revolutionizes felt production.

What Is Felt and Why Is It Special?

Felt’s unique texture poses challenges. Hand-cutting leads to uneven edges. This frustrates crafters and manufacturers alike.

Felt is a non-woven fabric made from compressed fibers, often wool or synthetic. Its dense, soft structure suits laser cutting, enabling precise shapes for crafts and industry.

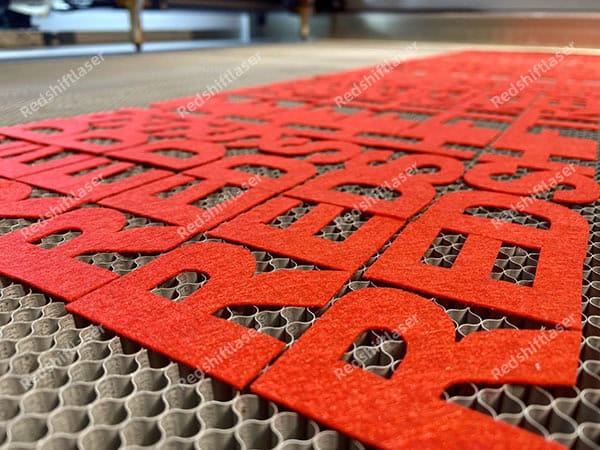

At Redshift Laser, I worked with a craft supplier. Their manual cuts on wool felt were inconsistent. Switching to lasers transformed their output. Orders surged.

Felt comes in two types: wool and synthetic. Wool felt, made from sheep fibers, is soft and eco-friendly. Synthetic felt, often polyester, is durable and cheap. Both cut well with lasers.

Wool Felt Benefits

Wool felt holds shapes well. I’ve seen it used for coasters. Lasers cut it cleanly at 0.1mm precision.

Synthetic Felt Uses

Synthetic felt resists moisture. It’s great for bags. Lasers handle its 1-5mm thickness without burning.

| Felt Type | Source | Key Feature | Laser Fit |

|---|---|---|---|

| Wool | Sheep fibers | Soft, eco-friendly | Excellent, clean cuts |

| Synthetic | Polyester | Durable, water-resistant | Great, no burns |

This table shows felt’s versatility. Thickness matters. Most felt is 1-3mm. Lasers cut up to 10mm with multi-pass.

Testing is crucial. I always run samples. One client’s thick felt scorched until we adjusted power.

Felt’s density makes it ideal for lasers. It opens creative doors for businesses.

How Does Laser Cutting Work for Felt?

Cutting felt sounds simple. But its fibrous nature trips up traditional tools. Precision is hard to achieve.

Laser cutting felt uses a CO2 laser beam to vaporize material. Focused at 0.1mm, it cuts and seals edges, preventing fraying. Tools include laser beds and design software.

I helped a felt ornament maker two years ago. Their scissors left ragged edges. We introduced a CO2 laser. Their designs came out flawless.

The process is straightforward. A CO2 laser, typically 40-100W, heats felt until it vaporizes. The beam follows a digital design from software like RDWorks.

Key Tools

Laser beds, often 900x600mm, hold felt flat. Auto-feed systems handle rolls. Exhaust units remove fumes, as felt can smell when cut.

Power Settings

Power settings vary. Wool felt needs 60W for 3mm. Synthetic felt cuts at 50W to avoid melting.

| Component | Role | Specification |

|---|---|---|

| CO2 Laser | Cuts material | 40-100W power |

| Laser Bed | Holds felt | 900x600mm or larger |

| Software | Guides laser | RDWorks, AutoCAD |

| Exhaust | Removes fumes | HEPA filter |

This table outlines the setup. Maintenance is easy—clean lenses every 500 hours. Blades need daily sharpening.

This process ensures clean, repeatable cuts. It’s a game-changer for felt projects.

What Are the Top Advantages of Laser Cutting Felt?

Manual felt cutting wastes time. Edges fray. Scrap piles up. These issues hurt small businesses.

Laser cutting felt offers precision, speed, sealed edges, low waste, and design flexibility. It cuts production time by 50% and scrap by 25%, boosting efficiency.

A felt toy maker I worked with struggled with slow hand cuts. Their scrap rate was 20%. Lasers dropped it to 5%. They doubled orders.

Let’s break it down. Precision tops the list. Lasers cut at 0.1mm accuracy, perfect for intricate patterns like felt flowers.

Speed Gains

Speed is huge. Lasers cut at 80m/min, versus 15m/min for scissors. This frees workers for other tasks.

Sealed Edges

Edges seal instantly. No fraying. This skips sewing steps, saving hours.

Waste Reduction

Waste drops to 5%. Hand tools hit 20%. This saves material costs yearly.

Design Freedom

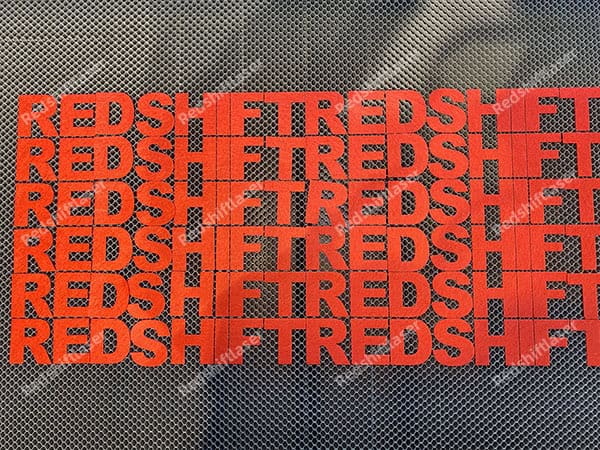

Lasers handle complex shapes. Think custom logos or layered designs. Upload and cut in minutes

| Advantage | Manual Cutting | Laser Cutting |

|---|---|---|

| Precision | ±1mm | ±0.1mm |

| Speed | 15m/min | 80m/min |

| Waste | 20% | 5% |

| Edge Quality | Frayed | Sealed |

| Design Setup | Hours | Minutes |

This table shows clear wins. A client saw ROI in six months. Safety improves too—no blades, fewer injuries.

Lasers use 2kW, less than mechanical cutters at 4kW. Eco-friendly and cost-saving.

These advantages streamline production. I’ve seen crafters thrive with lasers.

How Is Laser-Cut Felt Used Across Industries?

Felt’s versatility shines in many fields. But cutting it precisely is tough without the right tools.

Laser-cut felt is used in crafts, fashion, automotive, and home decor. It creates coasters, bags, car interiors, and acoustic panels with clean, custom shapes.

I helped a fashion brand cut felt for hats. Manual tools slowed them down. Lasers delivered perfect shapes, boosting their sales.

Crafts lead the way. Lasers cut felt for ornaments and toys. A client made 1,000 coasters in a day, all precise.

Fashion and Accessories

In fashion, felt becomes bags and hats. Lasers cut intricate patterns, like floral designs, in minutes.

Automotive Uses

Automotive uses felt for soundproofing. I worked with a car parts supplier. Lasers cut panels for dashboards, reducing noise.

Home Decor

Home decor includes acoustic panels. Lasers shape thick felt for studios, cutting waste by 20%.

| Industry | Use Case | Laser Benefit |

|---|---|---|

| Crafts | Ornaments, toys | Precise shapes |

| Fashion | Bags, hats | Intricate patterns |

| Automotive | Soundproofing | Clean edges |

| Decor | Acoustic panels | 20% less waste |

This table shows applications. Thickness varies—1mm for crafts, 5mm for automotive. Lasers adjust easily.

Ventilation is key. Felt fumes need HEPA filters for safety.

Testing prevents errors. One client’s synthetic felt melted. We lowered power to fix it.

These uses highlight felt’s creative potential with lasers.

How Well Does Felt Pair with Laser Cutting?

Felt’s unique properties raise questions. Will it burn? Can lasers handle its density? Answers matter.

Felt pairs well with laser cutting due to its dense, non-woven structure. CO2 lasers cut wool and synthetic felt cleanly, sealing edges without burning when settings are optimized.

A client doubted lasers for thick felt. We tested 5mm wool felt. The results were flawless, and they ordered a machine.

Felt’s fibers compress tightly, making it ideal for lasers. Wool felt cuts best at 60W. Synthetic needs 50W to avoid charring.

Thickness Handling

Lasers cut 1-10mm felt. Multi-pass handles thicker pieces. I’ve cut 8mm for acoustic panels smoothly.

Material Response

Wool felt seals perfectly. Synthetic felt needs air assist to prevent melting. Both resist fraying post-cut.

| Property | Wool Felt | Synthetic Felt |

|---|---|---|

| Cut Power | 60W | 50W |

| Thickness | 1-10mm | 1-8mm |

| Edge Finish | Sealed | Sealed with care |

| Fume Risk | Moderate | Higher |

This table explains compatibility. Testing is key. I run samples to set power right.

Ventilation matters. Felt fumes smell. Our HEPA systems keep air safe.

How Can You Master Laser Cutting for Felt?

Mastering laser cutting takes practice. Wrong settings burn felt. Precision requires know-how.

To master laser cutting felt, optimize power (50-60W), use air assist, test samples, and integrate CAD software. This ensures clean cuts and efficient production.

I trained a team on laser settings. They struggled with burns. After adjusting power and air, their cuts were perfect.

Start with power. Wool felt needs 60W for 3mm. Synthetic uses 50W. Test on scraps first.

Air Assist

Air assist cools cuts. It prevents charring on synthetic felt. I use 20psi for clean results.

Software Integration

CAD software like RDWorks speeds design. Upload patterns and cut instantly. It saves hours.

| Technique | Purpose | Tip |

|---|---|---|

| Power Setting | Clean cuts | 50-60W, test first |

| Air Assist | Prevent burns | 20psi for synthetics |

| Sample Testing | Avoid errors | Run small cuts |

| CAD Use | Fast design | RDWorks or AutoCAD |

This table guides mastery. Training takes a day. Our videos help operators learn fast.

Maintenance is simple. Clean lenses monthly. Check air filters for fumes.

Master these, and your felt cuts will shine.

What Are Quick Solutions for Laser Cutting Felt?

Issues like burns or fumes can stall production. Quick fixes keep things running smoothly.

Quick solutions for laser cutting felt include lowering power to 50W, using air assist, adding HEPA ventilation, and testing samples to prevent burns and ensure clean cuts.

A client faced burnt felt edges. We lowered power and added air assist. Problem solved in an hour.

Lower power to 50W for synthetic felt. It prevents melting. Wool felt can take 60W.

Ventilation Fix

Fumes are common. Install HEPA filters. They capture 99% of particles, keeping air safe.

Sample Testing

Test cuts avoid waste. I run 10cm samples to dial in settings.

| Issue | Solution | Impact |

|---|---|---|

| Burns | Lower to 50W | Clean edges |

| Fumes | HEPA filter1 | Safe air |

| Inaccuracy | Test samples | Zero waste2 |

| Slow Setup | CAD software | 70% faster |

This table lists fixes. Air assist at 20psi cools cuts. CAD integration speeds setup.

These fixes keep your felt cutting smooth and fast.

Conclusion

Laser cutting felt delivers precision, speed, and creativity. From crafts to automotive, it transforms production. Master it to create stunning, efficient felt products.