Designers are thrilled by the intricate patterns they can create on shoes with a laser. But as a manufacturer, you see the hidden danger: every beautiful cut is a potential point of failure. Customers are initially attracted by the design, but get angry when the shoe rips after a few months. You are caught between market demand for visual complexity and the risk of producing a structurally weak product.

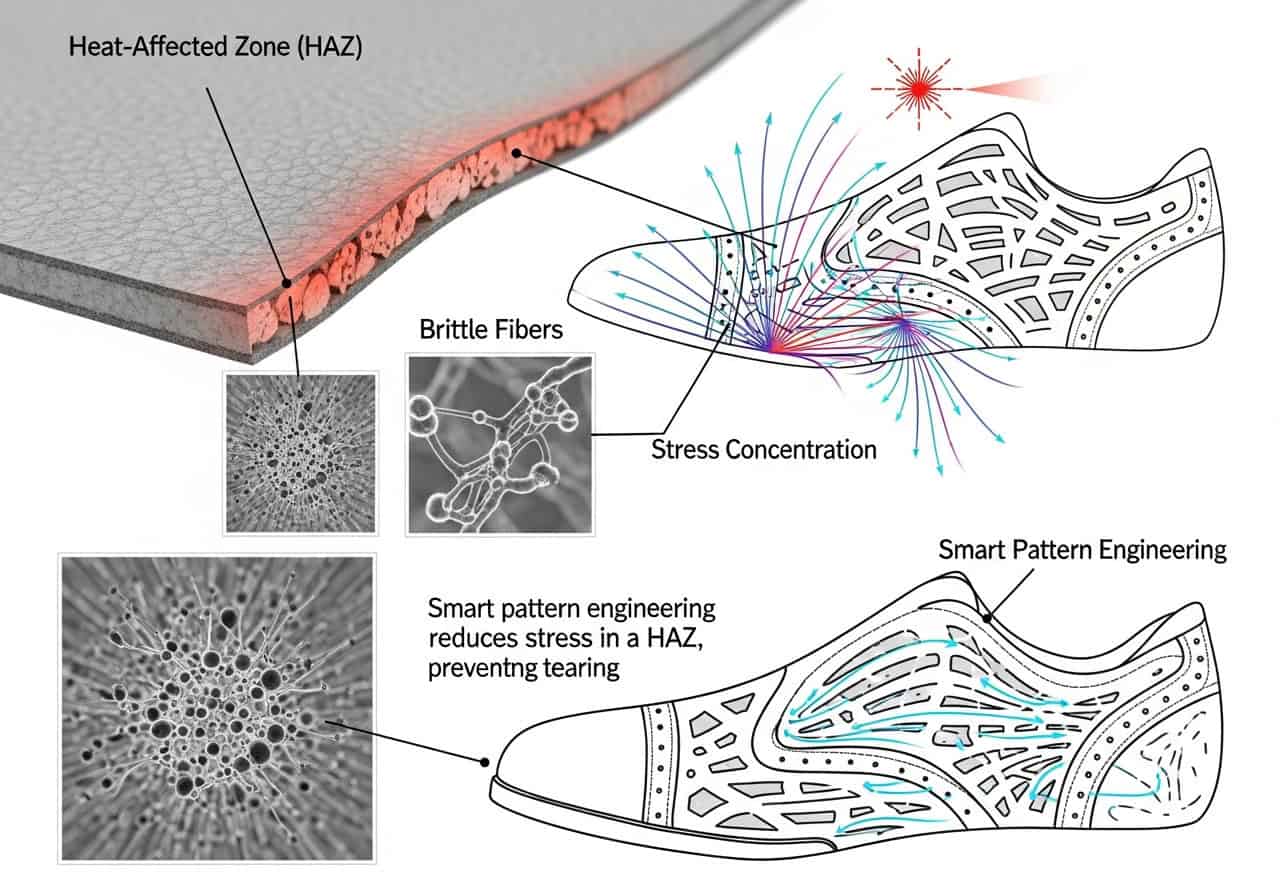

The secret to creating durable laser-cut shoes is to engineer the design with material science in mind. It's not just about the pattern, but about managing the Heat-Affected Zone (HAZ) created by the laser. True expertise lies in creating designs that distribute stress away from these thermally-altered areas, ensuring that an ornate hole for ventilation doesn't become the starting point for a catastrophic tear.

I remember working with a boot company that was excited to launch a new line with a very intricate, leaf-like pattern cut into the ankle support. The prototypes looked fantastic. But when they wear-tested them, a tear started at the sharpest point of a leaf on nearly every pair. They were focused on the visual art, but they had overlooked the physics. We had to go back and help them redesign the pattern, rounding the sharp internal corners and adding subtle structural bridges. This small change managed the stress points, and the final product was both beautiful and tough.

What Kind of Diverse Laser-Cut Designs Can Be Made on Shoes?

You see popular brands releasing shoes with complex laser-cut patterns. You want to offer similar designs, but you're worried about the production challenges. Creating these designs seems complex, and you fear that they might not hold up to everyday use, leading to customer complaints and returns. This makes you hesitate to adopt the technology.

A CO2 laser cutter can create an incredible variety of shoe designs with precision. This includes modern digital broguing, geometric ventilation patterns, intricate floral motifs, and precise logo etching. The key is that these designs are not just decorative; they can also be functional, providing breathability and flexibility. The laser's accuracy allows for patterns far more complex than traditional methods can achieve.

Moving Beyond Simple Perforation

Laser cutting opens up a world of design possibilities that directly impact a shoe's appeal and function. For a purchasing manager like John, understanding these applications is key to identifying market opportunities.

1. Digital Broguing and Decorative Etching

Traditional broguing involves punching holes in leather. A laser can replicate these classic patterns with much greater detail and can also etch fine-line patterns onto the surface without cutting all the way through. This allows for branding, textures, and designs on finished shoes without compromising the material's main structure. The HAZ is minimal in surface etching, making it a very safe design choice.

2. Functional Ventilation Patterns

For athletic shoes and summer footwear, breathability is essential. Lasers can cut precise geometric or organic patterns that allow for airflow. The engineering challenge here is to ensure the pattern's "bridges"—the material left between the cuts—are wide enough and shaped correctly to handle the flexing and stress of walking or running.

3. Layered and Multi-Material Designs

Lasers excel at cutting intricate overlays. Imagine a synthetic upper with a fine mesh pattern laser-cut into it, which is then bonded over a contrasting fabric base layer. This creates visual depth and texture. The laser's precision ensures that the two layers align perfectly, a task that is nearly impossible with manual or die cutting.

How Do You Start a Laser-Cutting Shoe Business?

You see the potential in offering custom, laser-cut footwear, but the path to starting this business seems unclear. You are facing questions about design, materials, machinery, and finding customers. The fear of making a large investment in the wrong equipment or failing to find a market can be paralyzing, stopping you before you even begin.

Starting a laser-cutting shoe business requires a focused plan. First, identify your niche market, whether it's custom sneakers, bespoke leather shoes, or orthopedic footwear. The next step is to invest in a reliable CO2 laser cutter and learn design software. Most importantly, create prototypes that are rigorously tested for durability, paying close attention to how your laser-cut designs hold up under stress before going to market.

A Practical Roadmap for Success

For a professional like John advising a new venture, or for an entrepreneur entering the market, a structured approach is essential. It’s not just about buying a machine.

1. Market Research and Niche Identification

Don't try to serve everyone. Will you focus on high-fashion, one-off custom designs for individuals? Or will you supply pre-cut upper components to larger footwear manufacturers? Or perhaps create orthopedic shoes with custom ventilation? Your niche will determine your machine choice, material inventory, and marketing strategy.

2. Prototyping with a Focus on Failure Testing

This is where the core insight is critical. Your first step after creating a design is to try and destroy it. Use a force gauge to pull at the cut patterns. Flex the material thousands of times. Wear the prototype for a week. Document where the stress points are. Use this data to refine your designs for longevity. This shifts your thinking from "designer" to "engineer."

3. Equipment and Software Investment

Your CO2 laser is your primary tool. Don't just look at the price. Consider the bed size (can it fit a full hide of leather?), the laser power (does it match your materials?), and the quality of the motion system (for accuracy). Equally important is the software—is it easy to import designs from standard programs like Adobe Illustrator or CorelDRAW?

How Do You Select the Right Shoe Laser Cutting Machine?

You're ready to invest in a laser cutter for shoe production, but the technical specifications are confusing. Choosing a machine with the wrong power, size, or features could lead to poor cut quality, slow production, and wasted material. This decision is a significant capital expense, and you feel the pressure to get it absolutely right.

Selecting the right laser cutter for shoes involves balancing three factors: material compatibility, production scale, and design complexity. A CO2 laser with a power of 80-150W is ideal for leather and synthetics. Your production volume will determine the required bed size and whether you need automation features like a camera for registration or a conveyor system for continuous cutting.

Key Machine Specifications for Shoe Production

This is a decision I help clients like John with every day. Let's break down the technical choices into practical business decisions.

1. Laser Source and Power (CO2 vs. Fiber)

For the materials used in footwear—leather, textiles, rubber, and most synthetics—a CO2 laser is the correct choice. Its wavelength is readily absorbed by these organic materials. A laser power between 80W and 150W offers a sweet spot of cutting speed and manageable Heat-Affected Zone (HAZ).

2. Bed Size and Material Handling

Will you be cutting small, pre-cut pieces or large hides of leather? A small machine (e.g., 900x600mm) is fine for prototyping. For production, a larger bed (e.g., 1600x1000mm) with a conveyor system allows you to feed material continuously from a roll, maximizing throughput.

3. Vision and Registration Systems (Camera)

This is a game-changer for working with natural or pre-printed materials. A camera system can automatically recognize the outline of a hide to maximize nests and minimize waste. It can also find registration marks printed on the material to perfectly align cuts with a printed design, which is essential for sneakers and patterned uppers.

Machine Feature Comparison

| Feature | Importance for Prototyping | Importance for Production | Benefit |

|---|---|---|---|

| 80-150W CO2 Laser | High | High | Optimal for cutting leather, synthetics, and textiles. |

| Small Bed (900x600mm) | High | Low | Cost-effective for samples and small-batch custom work. |

| Large Bed (1600x1000mm+) | Low | High | Fits full hides of leather and large production runs. |

| Camera Vision System | Medium | Very High | Minimizes waste, aligns cuts to prints automatically. |

| Conveyor System | Low | High | Enables continuous roll-to-roll cutting for automation. |

What Materials Work Best for Laser-Cut Shoes?

You want to use a laser, but you're unsure which of your materials will cut cleanly. You worry about materials melting, burning, or releasing harmful fumes. Choosing an incompatible material could ruin a whole batch, damage your equipment, or create a hazardous work environment, causing costly delays and safety issues.

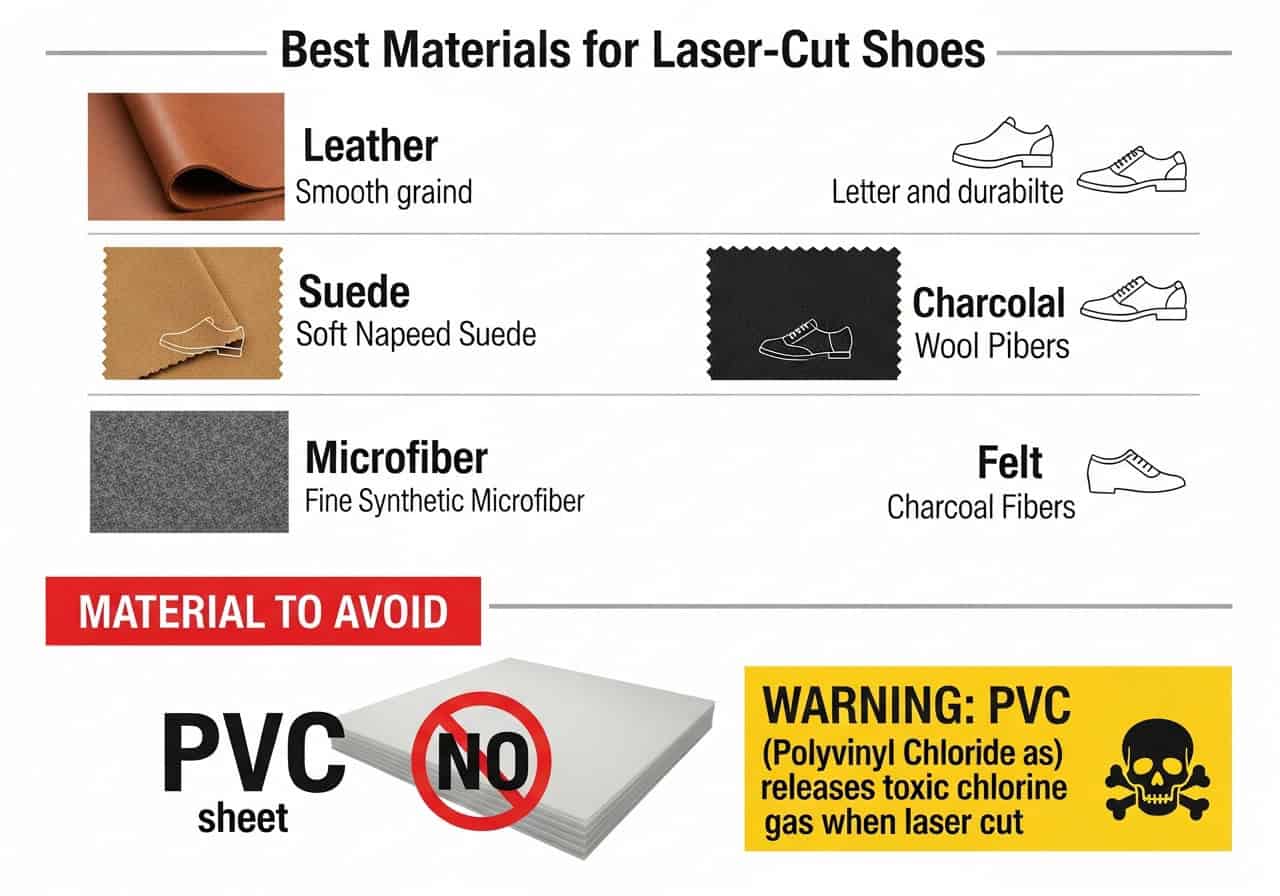

The best materials for laser-cut shoes are natural leather, suede, and many synthetic fabrics like microfiber, felt, and nylon textiles. These materials vaporize cleanly under a CO2 laser, leaving a sealed, non-fraying edge. However, it is critical to avoid materials containing chlorine, like PVC leatherette, as they release corrosive and toxic gas when burned. Always verify your material's composition.

Material Science for Laser Cutting

The laser reacts differently with each material. Understanding this is fundamental to quality control.

1. Natural Leather and Suede

Leather is perhaps the perfect material for laser cutting. It cuts cleanly, and the laser seals the edge, which can add to the durability of some designs. The process also creates a characteristic, slightly darkened edge that is often considered a desirable aesthetic feature. Suede also cuts beautifully, with the laser neatly searing the fine fibers.

2. Synthetic Textiles and Foams

Materials like felt, microfiber, and technical fabrics (like Cordura or nylon) cut exceptionally well. The laser melts the synthetic fibers at the edge, creating a perfectly sealed, fray-proof finish. This is a major advantage over knife cutting, which leaves a raw edge that can unravel. EVA foam for midsoles also cuts cleanly and precisely.

3. Materials to Avoid (The Dangers of PVC)

This is a critical safety warning I give all my clients. Never laser cut Polyvinyl Chloride (PVC), often found in cheap artificial leather. When heated, PVC releases hydrochloric acid as a gas. This gas is toxic to breathe and will instantly corrode the metal components of your laser cutter, causing catastrophic damage. Always demand a material safety data sheet (MSDS) from your supplier to ensure your material is PVC-free.

Conclusion

The appeal of laser-cut shoes is undeniable, but lasting success in this market is not built on aesthetics alone. It is built on engineering. The key takeaway is that every cut must be designed to manage stress and account for the Heat-Affected Zone. By shifting focus from just the pattern to the underlying material science, manufacturers can move beyond creating fragile, decorative items. They can produce innovative, beautiful, and—most importantly—durable footwear that delights a customer on day one and earns their loyalty for years to come. This approach turns a design feature into a mark of quality.

FAQ: Laser Cutting Shoes

Q1: Does laser cutting leather make it weaker?

A: It can if the design is poor. The laser creates a narrow Heat-Affected Zone (HAZ) where the leather is slightly embrittled. Good design practice involves avoiding sharp internal corners and ensuring there is enough material between cuts to distribute stress, preventing the HAZ from becoming a failure point.

Q2: Can I cut the sole of the shoe with a laser?

A: You can cut midsoles made from EVA foam and many rubber outsoles. However, very thick or dense rubber can be difficult and slow to cut. For thick outsoles, lasers are more commonly used for etching tread patterns or logos rather than cutting the profile.

Q3: What's the smell like when laser cutting leather?

A: Laser cutting any natural material produces a distinct smell. For leather, it is often described as similar to burnt hair. A proper fume and smoke extraction system is absolutely essential, not just for the smell but to remove airborne particles and ensure a safe and clean working environment.

Q4: Can I cut multiple layers of material at once?

A: Yes, you can cut multiple layers of thin materials like textiles, but it's generally recommended to cut one layer at a time for the best edge quality and accuracy. Cutting thick stacks can cause the laser beam to lose focus through the layers, resulting in a angled or inconsistent cut.

Q5: How does a laser compare to a die cutter for shoe production?

A: A die cutter is faster for very high volumes of a single, unchanging shape. A laser is superior for design flexibility (no tooling costs), intricate details, and prototyping. The laser also produces a sealed, non-fraying edge on textiles, which is something a die cannot do.

Q6: Is the dark edge on laser-cut leather removable?

A: The sealed, brownish edge on laser-cut leather is a result of the material being vaporized. While it can sometimes be lightly cleaned or buffed on certain types of leather, it's generally considered part of the laser-cut aesthetic. For many designs, this darker edge is used to add contrast and highlight the pattern.

Q7: Do I need special software to design for a laser cutter?

A: No, you can use standard vector design software like Adobe Illustrator, CorelDRAW, or Inkscape. You create your design as a vector file (.AI, .DXF, .SVG) and then import it into the laser's control software to assign cutting and engraving settings.

Q8: Can a laser engrave logos on a finished shoe?

A: Yes, this is a very common application. By reducing the laser's power, you can etch a logo or design onto the surface of a finished shoe without cutting through it. This is great for customization and branding. You would need a machine with a bed that can be lowered to accommodate the height of the shoe.

Q9: How do I prevent scorching or burn marks on light-colored materials?

A: You can minimize scorching by using "air assist"—a jet of compressed air directed at the cutting point which blows away excess heat and particles. You can also apply a layer of transfer paper or masking tape to the material's surface before cutting. The laser cuts through the tape, and any scorching occurs on the tape, which is peeled off afterward.

Q10: What is the most important safety feature for a shoe laser cutter?

A: A robust fume extraction system. Cutting leather and synthetics releases smoke and volatile organic compounds (VOCs). A high-quality filtration system that vents externally or captures and neutralizes these fumes is absolutely mandatory for operator health and safety.