You want to produce high-quality felt coasters, but your current die-cutting process is causing problems. The edges look fine at first, but after some use, they start to fray, leading to customer complaints and returns. This damages your brand's reputation for quality and forces you to consider costly manual finishing steps like sewing, which kills your profit margin. You're stuck between a low-quality product and an unprofitable one.

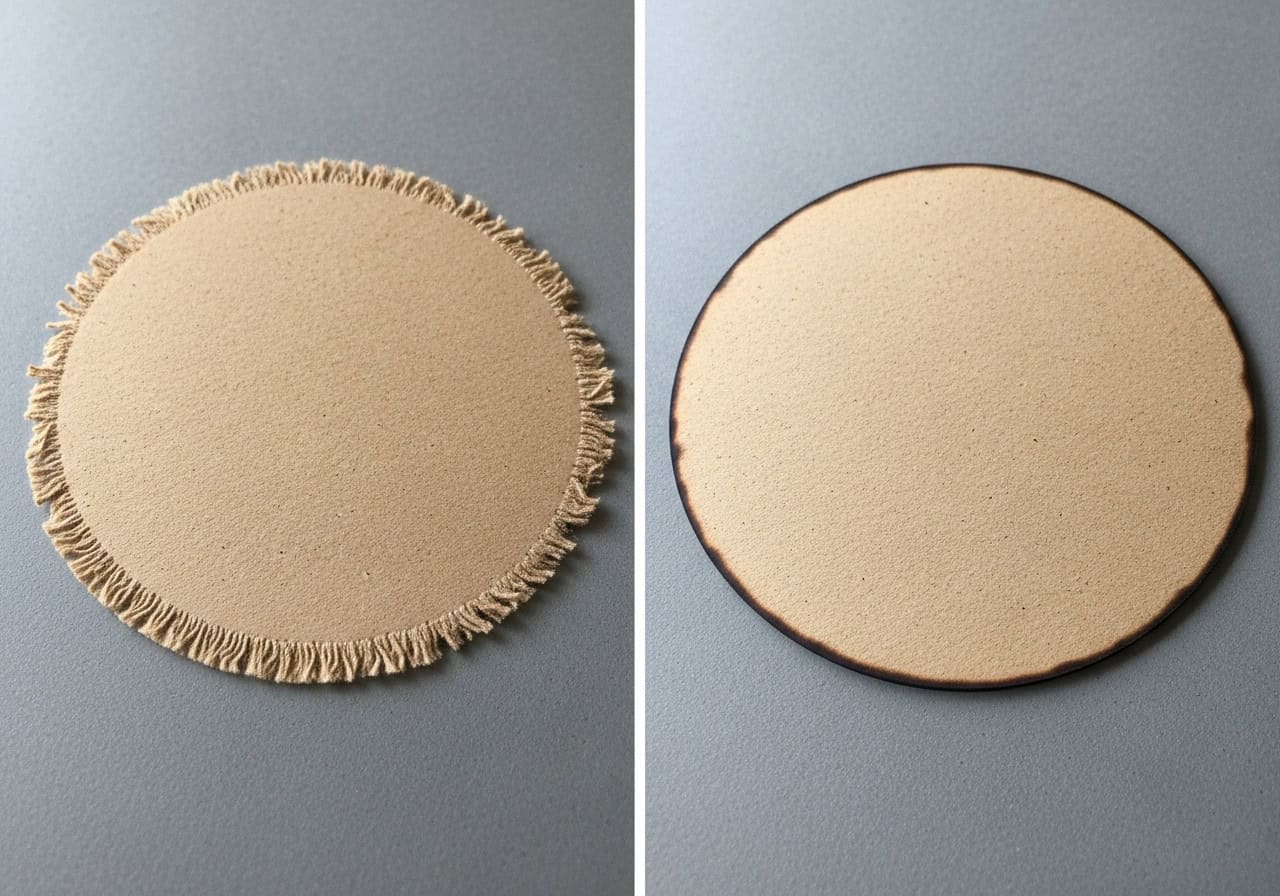

The perfect, durable edge on a laser-cut felt coaster comes from a precise thermal reaction, not from simple cutting. A CO₂ laser simultaneously vaporizes the natural wool fibers while melting the synthetic polyester fibers within the felt blend. When calibrated perfectly, this process creates a thermally sealed edge that physically cannot fray. This is a mark of superior durability that mechanical die-cutting can never achieve, turning a simple coaster into a premium, long-lasting product.

I remember talking with a client who made beautiful, printed felt coasters. Their business was struggling with online reviews complaining about the coasters looking "fuzzy" and worn out after a month. They were die-cutting a standard wool/poly blend. I explained that a die-cutter is a blunt force instrument; it tears fibers. We took their exact material and ran it through one of our CO₂ lasers. I showed them the edge under a magnifier—it was smooth, slightly shiny, and fused solid. The laser wasn't just cutting a shape; it was creating a permanent, finished edge in the same step. They made the switch, and their product return rate dropped to nearly zero.

What Is a CO2 Laser Actually Doing to the Felt?

You see a laser cutter as a kind of "light blade," but this mental model is confusing. It doesn't explain why sometimes the felt cuts cleanly, and other times it just turns into a charred mess. This lack of understanding makes you hesitant to invest in the technology, fearing you won't be able to control the results and will waste expensive material.

A CO₂ laser is not a blade; it's a source of intense thermal energy. It emits a beam of infrared light that natural and synthetic fibers absorb very efficiently. Instead of physically shearing the material, the laser's energy instantly heats the fibers. It's a non-contact process that flash-vaporizes some fibers while melting others, all within a tiny, focused spot. This is why it's a game of thermal management, not mechanical force.

For a purchasing manager, understanding the how is key to controlling the what. It's not magic; it is predictable materials science.

1. The Role of the CO₂ Laser

The CO₂ laser operates at a wavelength of 10,600 nanometers. This specific wavelength of infrared light is highly absorbed by organic materials (like wool) and many polymers (like polyester). This efficient energy absorption is what allows the laser to have such a dramatic thermal effect without ever touching the felt.

2. A Balancing Act: Wool vs. Polyester

Most commercial felt is a blend. Each component reacts differently to the laser:

- Natural Wool: Being an organic, protein-based fiber, wool doesn't melt. It absorbs the energy and flash-vaporizes (sublimates) or burns. Too much power here causes charring and a bad smell.

- Synthetic Polyester: As a thermoplastic polymer, polyester melts when it reaches a specific temperature. The laser heats it just enough to liquefy and flow. As the laser moves on, the melted polyester cools and solidifies, fusing the loose ends of the surrounding fibers.

3. The Perfect Cut: Calibrated Chaos

The "perfect cut" is a delicate balance. The laser's power and speed are calibrated to provide enough energy to vaporize the wool cleanly while simultaneously providing just the right amount of heat to melt the polyester into a smooth, sealed edge. This is the technical challenge and the ultimate advantage.

| Fiber Type | Laser Reaction | Result of Too Much Power | Result of Too Little Power |

|---|---|---|---|

| Natural Wool | Vaporizes / Sublimates | Charring, soot, bad smell | Incomplete cut, wispy fibers |

| Synthetic Polyester | Melts and fuses | Burning, melted globs | Incomplete cut, rough edge |

| Blended Felt | Balanced Vaporization/Melting | Charred, uneven edge | Frayed, incomplete cut |

Why Choose a CO2 Laser for Cutting Felt Coasters?

You already have a die-cutting machine that seems to work "well enough." Investing in a new laser system feels like a significant and possibly unnecessary expense. You are skeptical that the benefits of a laser can justify the cost, especially when your current process is established and understood by your team.

A CO₂ laser should be chosen for felt coasters because it solves the single biggest failure point of the product: fraying edges. While a die-cutter creates a structurally weak edge, the laser creates a thermally-sealed, highly durable edge. This directly translates to higher product quality, fewer customer returns, and a better brand reputation. The laser isn't just a different way to cut; it’s a better way to build.

For John, a decision comes down to numbers. The ROI of a laser is found in efficiency, quality, and flexibility.

1. Eliminating a Production Step

With die-cutting, a separate finishing step like sewing or applying an edge sealant is often needed to prevent fraying on a high-quality product. A laser cuts and seals in a single pass. This complete elimination of a labor-intensive step drastically reduces the cost per unit and speeds up production time.

2. Zero Tooling Costs or Wear

A die-cutting press requires custom-made steel rule dies for every single design. These dies are expensive, have long lead times to produce, and wear out over time, leading to inconsistent cuts. A laser uses a beam of light. There are zero tooling costs, a new design is just a new digital file, and the "tool" never gets dull.

3. Superior and Consistent Quality

A die press exerts immense pressure, compressing the felt and creating a slightly crushed edge that is prone to fraying. A laser is a non-contact process, so the felt is never compressed or distorted. Every cut is identical, from the first to the ten-thousandth, ensuring perfect quality control and product uniformity.

What Are the Design Possibilities With Laser-Cut Felt?

You're used to the limitations of your die-cutter. You know that sharp internal corners are impossible, intricate details are risky, and every new design means a huge investment in a new die. This mindset makes your product designs simple and conservative, risk-averse, missing out on market trends that favor complex and personalized products.

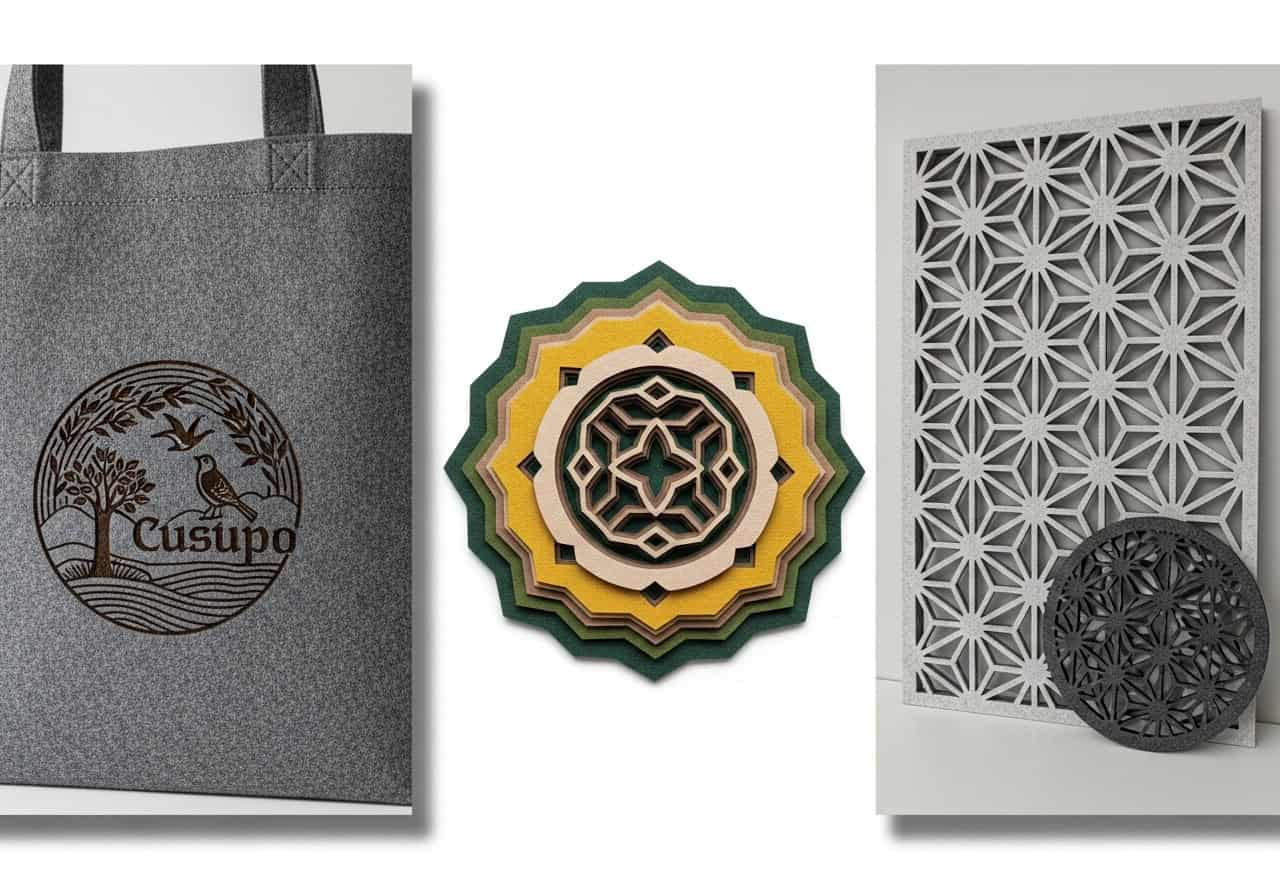

Laser technology completely removes the physical constraints of mechanical cutting, giving you nearly unlimited design freedom. You can create designs with incredibly fine details, sharp internal corners, and delicate latticework that would be impossible for a die-cutter to produce. This allows for rapid prototyping, on-the-fly customization, and the ability to offer a vast catalog of intricate designs without any tooling investment.

The laser doesn't just improve your current process; it enables entirely new business models.

1. Intricacy and Fine Detail

A laser beam can be focused down to a fraction of a millimeter. This allows you to cut patterns, text, and logos with a level of precision that is simply unachievable with a physical blade. You can create geometric patterns, city skylines, or delicate floral designs that turn a simple coaster into a piece of art.

2. Prototyping and Iteration at Zero Cost

Want to test a new coaster design? With a laser, you just need to edit a digital file. You can create a physical prototype in minutes. Compare this to the weeks and thousands of dollars it would take to order a new die. This agility allows you to respond to market trends instantly and perfect your designs without financial risk.

3. The Power of Personalization

Because there is no physical tool to change, a laser makes personalization effortless. You can offer customers the option to add their name, a special date, or a custom logo to their coasters. This model of mass customization is a huge value-add and a powerful market differentiator that is practically impossible to offer with die-cutting.

What Other Applications Can a Laser Handle on Felt?

You're now seeing the value of a laser for cutting coasters, but you're still thinking of it as a single-purpose machine. This narrow view might prevent you from seeing how a single capital investment in a laser cutter could open up entirely new product lines and revenue streams for your business, maximizing its ROI.

A CO₂ laser is a highly versatile tool that can do much more than just cut felt coasters. You can use the same machine for surface-level engraving to create debossed logos, kiss-cutting for multi-layer applications like patches and appliqués, and cutting a massive variety of other materials like wood, acrylic, leather, and paper. A laser cutter is not a single-task machine; it's a complete fabrication hub.

A laser cutter's value grows as you discover its full range of capabilities.

1. Surface Engraving and Marking

By reducing the laser's power, you can melt the surface fibers without cutting all the way through. This creates a darker, debossed effect perfect for adding permanent logos, part numbers, or branding to felt products. It's a more premium and durable alternative to printing.

2. Kiss-Cutting for Layered Products

Kiss-cutting involves precisely controlling the laser's power to cut through only one layer of material that is placed on top of another. This is the standard industry method for producing multi-color felt appliqués for apparel, intricate patches, or layered signage.

3. Expanding into Other Materials

The same CO₂ laser1 that perfectly cuts your felt coasters can also cut and engrave a huge range of other materials. This allows you to diversify your product offerings with minimal additional investment. You can create wood inlays for coasters, acrylic display stands, or engraved leather tags2, all on the same machine.

Conclusion

The beauty of a laser-cut felt coaster isn't just in its intricate design, but in the unseen science that makes it durable. The real advantage lies in a CO₂ laser's ability to delicately manage heat, vaporizing some fibers while melting others to forge a perfectly sealed, no-fray edge. This single-step process of cutting and finishing elevates the product, eliminates defects, and unlocks unlimited design freedom. It transforms a simple coaster into a premium good and a manufacturing process into a competitive advantage. This understanding of materials science is the true key to mastering quality and efficiency.

FAQs

Q1: Why do my die-cut felt coasters fray over time?

A: Die-cutting is a mechanical process that tears the felt fibers. This creates a structurally weak edge where the fibers are loose and easily pull apart with use, leading to a fuzzy, frayed appearance. It's a fundamental limitation of mechanical cutting.

Q2: How does a laser prevent the edges of felt coasters from fraying?

A: A CO₂ laser cuts with heat. On a blended felt (wool/polyester), it vaporizes the wool while melting the polyester. This melted polyester cools and solidifies, creating a thermally sealed edge where all the fibers are fused together, making it physically impossible for the edge to fray.

Q3: What's the biggest challenge when laser cutting blended felt?

A: The main challenge is thermal management. You must balance the laser's power and speed to cleanly vaporize the wool fibers without charring them, while simultaneously melting the polyester fibers without burning them. Perfect calibration is key to achieving a clean, sealed edge.

Q4: Do I need a special laser for cutting felt?

A: No, a standard CO₂ laser cutter is the perfect tool for the job. The critical factor isn't a special type of laser, but rather the ability to finely control the machine's settings (power, speed, and frequency) to match the specific felt blend you are using.

Q5: Is it better to use 100% synthetic felt for laser cutting?

A: For the easiest and most consistent results, yes. 100% polyester (PET) felt will melt uniformly, creating a very clean, sealed edge with a wider margin for error in your settings. Blended felts can also produce excellent results but require more precise calibration.

Q6: Can a laser engrave a logo onto a felt coaster?

A: Yes. By reducing the laser's power, it will only melt the surface of the felt without cutting through. This creates a darker, slightly debossed (sunken) mark which is very durable. This is an excellent way to add permanent branding.

Q7: Why is laser cutting more cost-effective for custom coaster designs?

A: With laser cutting, there are zero tooling costs. A new design is simply a new digital file. With die-cutting, every single new design requires a custom, expensive metal die to be manufactured, which is slow and costly, especially for small batches or prototypes.

Q8: Can a laser create very intricate, detailed designs on felt coasters?

A: Absolutely. This is a major advantage. A laser beam can cut extremely fine details and sharp internal corners that are physically impossible for a mechanical die to produce. This allows for far greater creative freedom and more sophisticated products.

Q9: What causes a "charred" or burnt look when laser cutting felt?

A: Charring is typically caused by having the laser power set too high or the speed set too low. This delivers too much thermal energy to the material, causing the natural wool fibers to burn instead of vaporize cleanly. Proper calibration is the solution.

Q10: Besides coasters, what else can I make with laser-cut felt?

A: The possibilities are vast. You can use the same process and machine to create architectural acoustic panels, premium packaging inserts, placemats, tech accessories (laptop sleeves), holiday ornaments, and multi-layer appliqués for apparel.