Struggling to create breathable sportswear that meets performance demands? Traditional perforation methods are often imprecise, can damage delicate fabrics, and fail to deliver the consistent quality athletes expect.

CO2 laser marking machines achieve superior precision by using a digitally controlled beam of light to vaporize fabric. This creates clean, sealed micro-perforations without physical contact, ensuring flawless consistency and complex pattern capability for enhanced sportswear design.

I've spent my life working with knitted fabrics. The difference between a good sock and a great one often comes down to the precision of the knit structure—how it stretches, how it breathes. When I first saw a CO2 laser perforating sportswear, it reminded me of that same need for precision, but on a whole new level. In the old days, creating holes meant physically punching the fabric, which was always a compromise. Now, factories can "draw" ventilation with light. This technology isn't just an upgrade; it’s a game-changer for creating high-performance apparel that looks as good as it feels.

What Makes CO₂ Laser Marking Better Than Fiber for Sportswear Perforation?

Choosing the wrong laser type for your fabrics can be a costly mistake. A fiber laser might seem powerful, but it can easily melt or burn delicate synthetics, wasting expensive material and time.

CO₂ lasers are superior for sportswear because their long wavelength is perfectly absorbed by synthetic fabrics like polyester and nylon. Fiber lasers use a shorter wavelength designed for metals, which can pass through or uncontrollably burn these non-metal materials.

Think of it like using the right key for a specific lock. The wavelength of a CO₂ laser (around 10.6 micrometers) is the perfect "key" to unlock and vaporize textile fibers. The fabric's molecules get excited by this specific energy and turn into gas, leaving a clean hole. A fiber laser, with its much shorter wavelength (around 1 micrometer), is the wrong key. It's designed for metals. When aimed at a synthetic fabric, its energy isn't absorbed properly. It might pass right through, or it might create hot spots that burn and melt the material, leaving behind a hard, rough edge instead of a clean cut. For a purchasing manager like Matt, who is responsible for quality, choosing the correct tool is fundamental. Using a CO₂ laser for fabrics prevents defects, reduces material waste, and ensures the final garment is soft and functional.

Laser Type vs. Material Suitability

| Laser Type | Wavelength | Best For | Result on Synthetic Fabric |

|---|---|---|---|

| CO₂ Laser | Long (10.6 µm) | Non-metals (textiles, wood, acrylic) | Clean, precise vaporization (Ideal) |

| Fiber Laser | Short (1.06 µm) | Metals, some plastics | Inconsistent cutting, melting, burning |

How Does CO2 Laser Perforation Improve Breathability and Comfort in Sportswear?

Athletes need gear that helps them manage heat and sweat, but standard fabrics can feel suffocating. This discomfort affects performance and can lead to customer dissatisfaction with your brand.

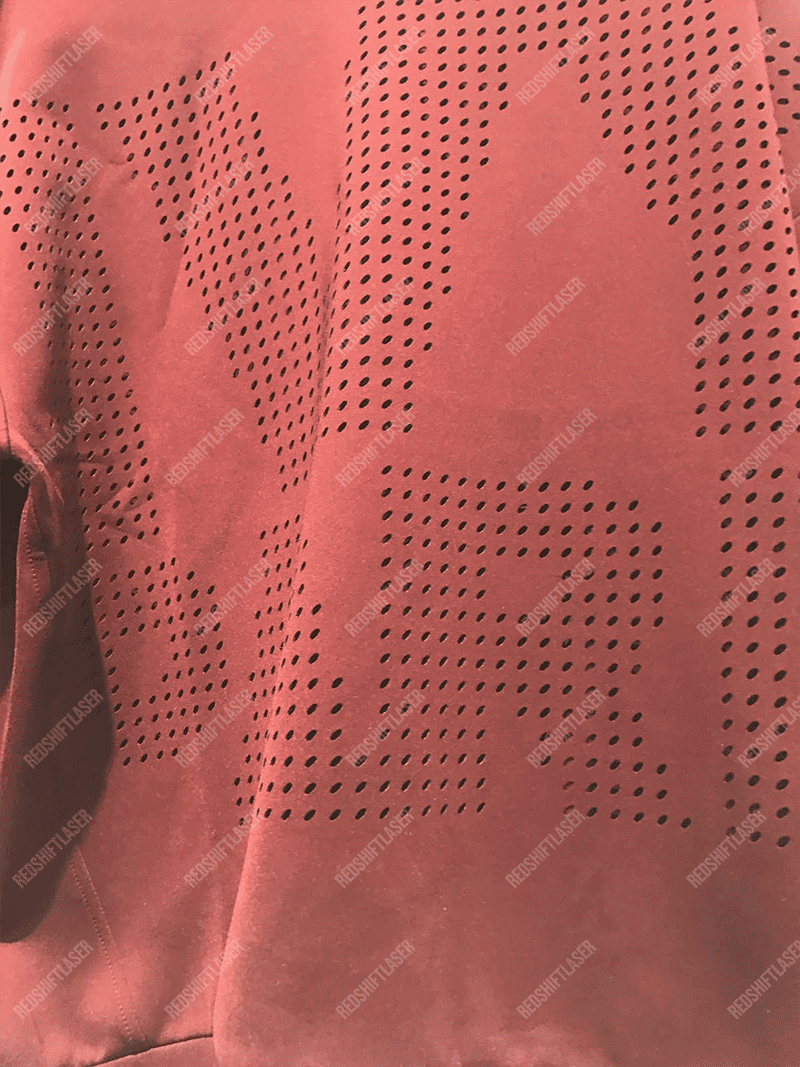

CO₂ lasers create thousands of perfectly uniform micro-perforations in key sweat zones like the back and underarms. This targeted ventilation system allows heat and moisture vapor to escape efficiently while promoting airflow, leading to superior comfort and performance.

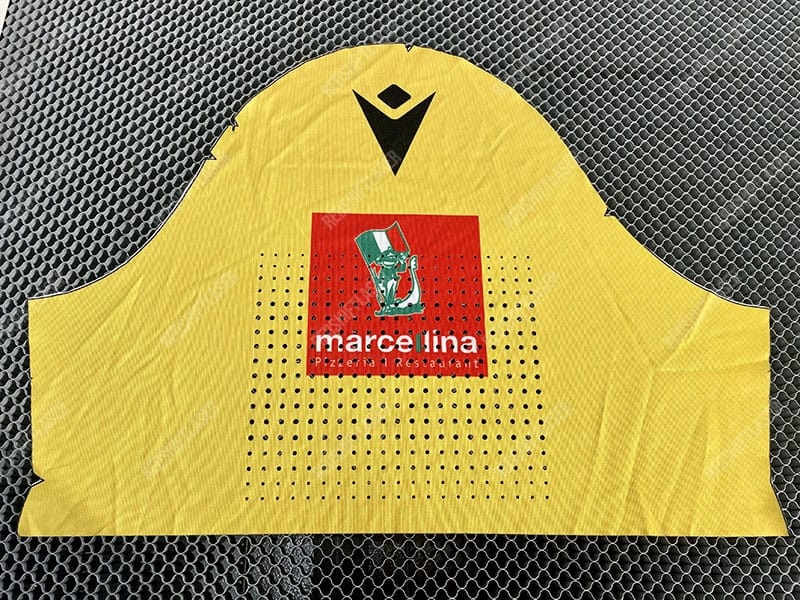

This technology allows designers to implement a concept called "body mapping." They can use data on where an athlete sweats most and create perforation patterns that precisely match those areas. It’s like designing a custom ventilation system for the human body. The laser can create a dense pattern of tiny holes on the back panel of a shirt while leaving the front solid, or add a subtle line of perforations along the legs of running tights. Because the process is digital, the size, shape, and density of these holes are infinitely adjustable. The result is a garment that breathes exactly where it needs to. Furthermore, because the laser seals the edges of each tiny hole as it cuts, the fabric remains smooth against the skin. There's no chafing or irritation, which is a common problem with mechanically created holes. This elevates a simple piece of clothing into a technical piece of high-performance equipment.

What Are the Advantages of CO₂ Laser Cutting Compared to Traditional Perforation Methods?

Relying on old methods like mechanical punching and die-cutting is slow and restrictive. Tools wear down leading to inconsistency, and design options are extremely limited, holding back your product innovation.

CO₂ laser cutting is a tool-less, non-contact process that offers limitless design flexibility. It creates perfectly sealed edges on synthetic fabrics to prevent fraying and eliminates tool wear, ensuring consistent quality and lower operating costs over time.

In my textile business, reducing process steps and ensuring consistency are keys to profitability. The laser cutting process does both. Traditional die-cutting requires a custom metal tool for every single pattern. This is expensive to create and useless for any other design. With a laser, the "tool" is just a digital file. You can switch from making small circles to intricate logos in seconds with zero tooling cost. The non-contact nature of the laser also means it doesn't pull or stretch delicate knit fabrics, which is a common issue with mechanical punching that leads to distorted patterns and defects.

Laser vs. Traditional Perforation

| Feature | CO₂ Laser Perforation1 | Traditional Methods (Punching/Die-Cutting)2 |

|---|---|---|

| Precision | Digitally controlled to the micrometer | Limited by tool size and mechanical tolerance |

| Edge Quality | Perfectly clean and sealed; no fraying | Often causes frayed edges that need finishing |

| Design Freedom | Virtually unlimited; complex patterns are easy | Very limited; restricted to the physical tool's shape |

| Tool Wear | None. The "tool" is a beam of light. | Tools become dull, requiring replacement and causing inconsistency |

| Speed | Extremely fast, especially for complex layouts | Slow; each hole is a separate mechanical action |

For a purchasing manager, the benefits are clear: faster production, lower defect rates, no recurring costs for new die tools, and the ability to offer brands far more innovative and complex designs.

How to Maintain CO₂ Laser Results and Ensure Consistent Quality in Manufacturing?

You have the best laser machine, but your output varies from one batch to the next. This inconsistency can lead to rejected orders and damage your reputation for quality with demanding clients.

Consistent quality is achieved through rigorous calibration, regular maintenance, and controlled environmental conditions. This includes cleaning the lenses daily, checking beam alignment weekly, and maintaining stable temperature and humidity levels in the factory to ensure uniform fabric interaction.

Just like my knitting machines, a CO₂ laser is a precision instrument that needs care to perform at its best. It's not a "set it and forget it" tool. The power of the laser beam can be affected by a tiny speck of dust on the lens or a slight shift in mirror alignment. That’s why top-tier factories have strict daily and weekly maintenance protocols. Operators start their day by cleaning the main lens and mirrors. They run calibration tests using a standard material to ensure the power output is exactly as specified in the digital file. The environment also plays a huge role. High humidity can affect how the fabric absorbs the laser's energy, so climate control in the laser room is essential. By treating the laser machine with the same respect as any other piece of precision manufacturing equipment, factories can guarantee that the ten-thousandth garment they produce has the exact same perforation quality as the first one.

Conclusion

CO₂ laser machines provide an unmatched level of precision and consistency for sportswear perforation. They enhance breathability, offer limitless design freedom, and boost production efficiency, making them an essential technology for any modern sportswear manufacturer.

Related: