In today’s fast-paced packaging industry, efficiency, precision, and customization are more important than ever. CO2 laser machines have emerged as powerful tools that meet these demands by offering non-contact, high-speed cutting and engraving solutions. Whether used for marking barcodes, cutting complex shapes, or adding branded elements to packaging, these machines are transforming the way manufacturers approach production.

One of the key strengths of CO2 lasers lies in their versatility across materials commonly used in packaging. From cardboard and corrugated paper to plastic films, wood, and certain coated metals, CO2 lasers can perform clean cuts and detailed engravings without physical wear on tools. This allows manufacturers to reduce production downtime, lower maintenance costs, and maintain consistent quality, even in high-volume or short-run packaging tasks.

Beyond material handling, CO2 laser technology plays a critical role in enhancing traceability and customization. For example, laser marking enables permanent, high-resolution coding—such as serial numbers, QR codes, or expiration dates—directly onto packages without using ink or labels. This not only reduces waste and consumable costs but also ensures compliance with regulatory requirements and boosts product security. Additionally, with rapid switching between design files, CO2 lasers allow businesses to quickly produce personalized or seasonal packaging, meeting growing market demands for agility and uniqueness.

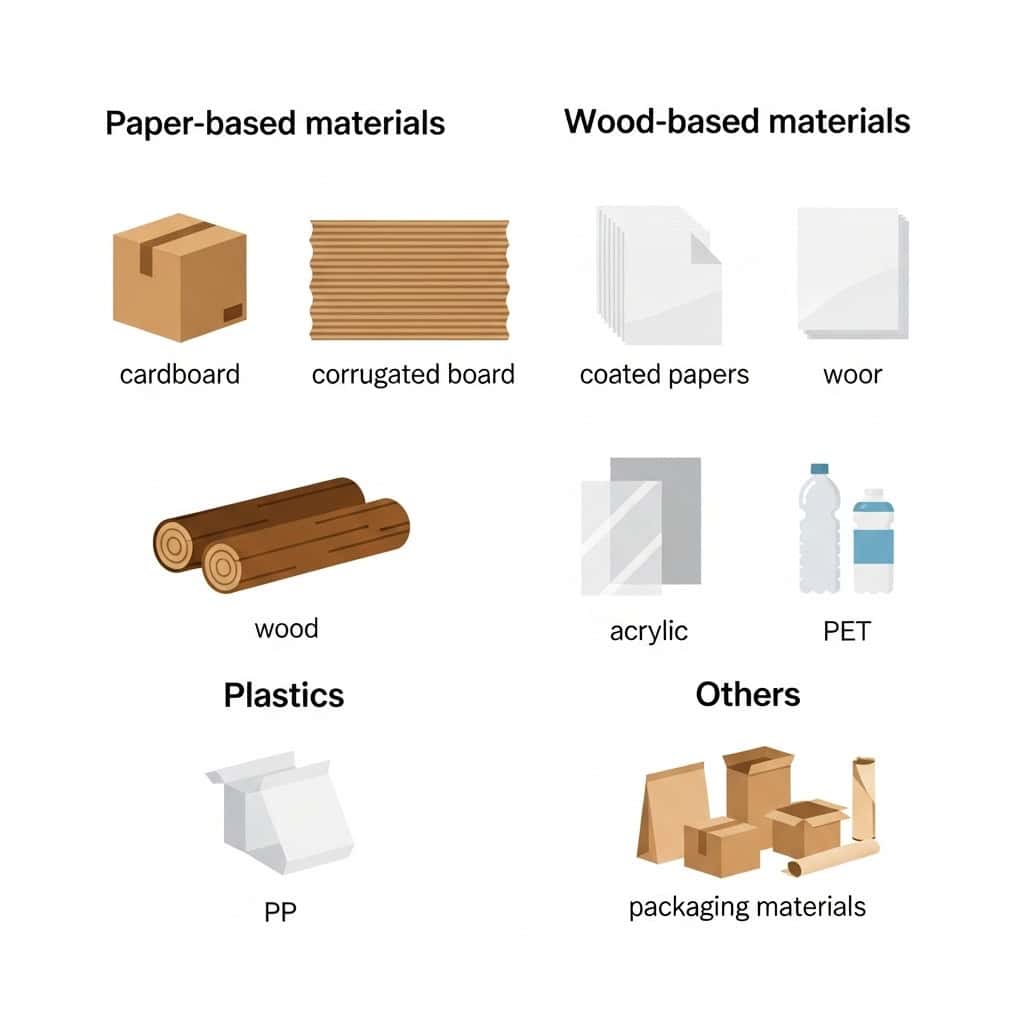

What materials can a CO₂ laser cut?

Packaging comes in many forms—from sturdy cardboard boxes and delicate films to wood or acrylic gift packaging. Not every tool can cut all these materials cleanly.

A CO₂ laser can cut or engrave most packaging materials, including cardboard, corrugated board, wood, acrylic, certain plastics (like PET and PP), and coated papers.

CO₂ laser machines use an intense focused beam of infrared light, which is quickly absorbed by organic and some synthetic materials. This makes them incredibly versatile for packaging applications.

Common Laser-Friendly Packaging Materials:

| Material | Cut | Engrave | Comments |

|---|---|---|---|

| Cardboard/Chipboard | Yes | Yes | Fast, precise cuts; complex patterns possible |

| Corrugated Board | Yes | Yes | Clean edges, custom inserts |

| Paper | Yes | Yes | Invitations, custom branding |

| Wood (e.g. gift boxes) | Yes | Yes | Logos, details, personalizations |

| Acrylic | Yes | Yes | Window cutouts, rigid packaging |

| PET Film | Yes* | Yes | Needs care—thin films work best |

| Polypropylene (PP) | Yes | Yes | Popular for flexible packs |

| Laminates | Yes | Yes | Layer-by-layer control for effects |

| Leather/Fake leather | Yes | Yes | Premium packaging accents |

*Some plastic films (like PVC or fluoropolymers) can release toxic fumes—never use a CO₂ laser on these.

Cardboard and wood cut smoothly, leaving sharp, slightly darkened edges. Thin PET films can be kiss-cut or engraved for tamper-evident features. Paper and paperboard stack up for everything from hang tags to luxe invitation sleeves. Each job needs its own speed and power settings, but the point is simple: with the right parameters, CO₂ lasers handle almost every common packaging material.

What is laser marking for traceability?

Manufacturers handling recalls or quality control know the pain of missing or unreadable batch codes. Manual labeling is slow and can wear off, which complicates traceability.

Laser marking is a high-speed, permanent way to add serial numbers, dates, barcodes, or logos to packaging for traceability. The marks resist abrasion, can't be washed off, and are easily verified.

Traceability is critical in modern packaging, whether for food safety, pharmaceuticals, or luxury goods. CO₂ laser marking stands out for a few reasons:

- Permanence: Unlike ink, laser marks never fade, smear, or wash off. Heat from the laser chemically alters the material’s surface, creating contrast.

- Speed: Marks are made in milliseconds and can be applied anywhere along the line.

- Accuracy: Variable data (like serials or batch numbers) can be generated and marked instantly, driven by your ERP or labeling software.

- Quality: High-contrast codes (like QR or DataMatrix) are easy for scanners to read.

| Traditional Labeling | Laser Marking |

|---|---|

| Can fade, peel, smear | Permanent, high-contrast |

| Needs consumables | No ink, ribbon, or stickers needed |

| Slower to change info | Instant variable-data capability |

For one food company I worked with, manual ink stamps led to recalls when codes wore off in shipping. The CO₂ laser eliminated that risk. Every box, no matter the shift or environmental condition, got a clear, permanent, machine-readable mark—giving them airtight traceability[^1] with zero manual errors.

How to make a CO₂ laser more effective in Custom Packaging Design?

Getting custom packaging done in short runs was once expensive and slow due to tooling, setup costs, and long lead times. This holds back creativity and fast brand updates.

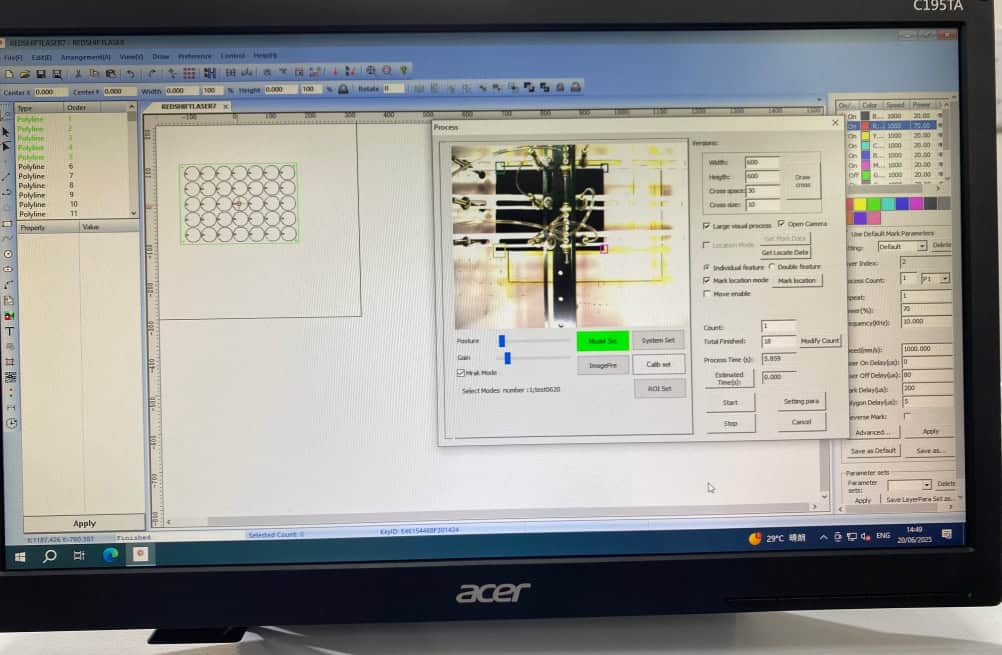

With digital CO₂ laser processing, custom packaging designs are possible at low cost—even for short and variable batch runs. Design changes are instant, with no need for physical dies.

Customization is the new expectation, not just a luxury, especially for brand launches, influencer kits, seasonal promotions, or personalized gifts. The magic of CO₂ laser lies in its “digital die”—the laser itself is the tool, driven by a CAD file.

Making Custom Design Easy:

- No Physical Tooling: Change out a logo, a pattern, or a cut shape with a few clicks in your design software.

- Fast Prototyping[^2]: Test new ideas and see the physical result within minutes, not days or weeks.

- True Low-Volume Production[^3]: Each item can have its unique QR code, name, or design—ideal for limited runs or serialized products.

- Precision & Complexity: Go beyond what steel dies can do. Create detailed filigree, layered windows, or multi-level engravings.

- Lower Costs, Less Waste: No expensive knife molds, no setup time, and just-in-time production reduces raw material waste.

| Traditional Custom | CO₂ Laser Custom |

|---|---|

| High MOQ | Any quantity |

| Steel dies/testers | Zero tooling |

| Days/weeks to swap | Change in seconds |

I’ve worked with startups launching crowd-funded products[^4] where the package is part of the story. With CO₂, every backer got a box engraved with their name[^5], all done in a single afternoon—no minimums, no delays.

What are the safety considerations for packaging?

Fast-moving packaging lines bring people and high-powered lasers close together. Without proper precautions, operators could be at risk for burns, eye injuries, or indoor air hazards.

Key CO₂ laser safety measures include: using enclosures/shields, proper ventilation or fume extraction, certified eye protection, lock-out/tag-out protocols for maintenance, and regular safety training for all staff.

Integrating CO₂ laser equipment into busy packaging operations requires careful safety planning, but it’s not complicated. These are the essential points every packaging manager needs to oversee:

Vital Safety Steps:

- Enclosures and Shielding: All laser heads should be in protective cases or guarded areas to prevent direct exposure. This blocks stray beams, which can burn skin or cause eye damage.

- Ventilation and Fume Extraction: Cutting and engraving release fine particulates and fumes—especially from plastics or coated stocks. Dedicated exhaust systems keep the workspace air safe and clear of flammable dust.

- Eye Protection: CO₂ lasers are invisible infrared. Only staff with approved, rated eyewear and proper training should ever be near open systems. Most modern machines are fully enclosed.

- Lock-Out/Tag-Out: Machines should be clearly labeled and locked during cleaning or repair to prevent accidental activation.

- Routine Maintenance & Checks: Dust buildup, worn seals, or loose optics increase fire risk and reduce quality. Scheduled cleaning keeps both safety and productivity high.

- Staff Training: Everyone ought to understand the basics—what to do in an emergency, how to check for leaks, and when to call in a supervisor or technician. Regular drills help keep the team ready.

| Risk | Solution |

|---|---|

| Eye injury | Full enclosure, rated eye shields |

| Fume inhal. | Strong exhaust/fume extract system |

| Burns | Physical barriers, lock-out |

| Fire/overheat | Dust clearing, thermal shutdowns |

Following these steps, the CO₂ laser becomes just another safe, reliable tool on the line—boosting speed and flexibility without compromising worker safety.

Conclusion

CO₂ laser machines transform the packaging industry with rapid customization, permanent traceability, and multi-material flexibility—while proper safety keeps productivity and people protected.

Related:

[^1]: Learn about the importance of airtight traceability in food safety and how it helps maintain quality control throughout the supply chain.

[^2]: Explore this link to understand how fast prototyping can revolutionize your design process, saving time and enhancing creativity.

[^3]: Discover the advantages of true low-volume production, perfect for unique designs and limited runs, enhancing your product offerings.

[^4]: Exploring this resource will provide insights into successful strategies for launching crowd-funded products, enhancing your project.

[^5]: This link will guide you on creating personalized packaging, which can significantly enhance customer engagement and satisfaction.