You see the intricate wooden designs online—the delicate ornaments, the personalized signs, the stunning home decor—and you think, "the possibilities are endless." You imagine your factory floor humming with lasers, churning out perfect products. But after running just one machine for a day cutting MDF, the air is thick with a hazy, acrid smoke. Your staff is complaining, a fine layer of dust coats everything, and you realize the "endless possibilities" come with a serious, hidden problem that can shut down your operation.

The real story of scaling laser-cut wood production isn't about design; it's about managing the massive amount of fumes, residue, and chemical off-gassing. Materials like plywood and MDF release significant particulates and formaldehyde, creating safety risks and compliance issues. Profitability isn't just determined by laser speed, but by your investment in industrial-grade ventilation and filtration. Mastering your air quality is the true key to unlocking those "endless possibilities" safely and efficiently.

From my five years at Redshift Laser, I've seen this firsthand. A client, much like my experienced contact John, once invested in a suite of three of our top-of-the-line lasers to produce wooden gift boxes. He was focused on the cutting speed and precision. But a month later, he called me in a panic. His production had been halted by a safety inspector. His workshop's basic exhaust fans were completely inadequate for the volume of MDF dust and fumes. The real investment, as he painfully learned, wasn't just the lasers. It was the robust, commercial-grade air filtration system needed to run them safely. This is the factory floor truth that we need to talk about.

What Wood Crafts Are Actually Profitable to Laser Cut?

You're inspired by the creative potential of laser-cutting wood, but you need to know which products will actually generate a return. It's easy to make a few cool-looking trinkets, but building a business requires identifying items that people are willing to pay a premium for. You need to find the sweet spot between creative expression and commercial viability.

Without a clear product-market fit, you risk investing time and expensive materials into a large inventory that just sits on the shelf. The key to profitability is leveraging the laser's unique strengths: intricate detail, deep personalization, and repeatability. By focusing on applications where these qualities are highly valued, you can create products that stand out in a crowded market and command a higher price, turning your laser into a real profit center.

The most profitable laser-cut wood crafts are customizable, high-value items that are difficult or time-consuming to produce with traditional methods. These include multi-layered 3D art and decor, personalized business signage, intricate jewelry and fashion accessories, and custom architectural models. These products succeed because they merge the natural beauty of wood with a level of precision and customization that customers see as premium.

Personalized Home Decor and Art

This is a huge market. Customers love unique items for their homes. Lasers can create multi-layered mandalas, custom name signs for nurseries, or intricate world maps. The ability to add a family name or a special date makes these items highly desirable as gifts. They have a high perceived value compared to their material cost.

- Products: 3D wall art, custom name signs, engraved photo frames, holiday ornaments.

- Value Add: Personalization, intricate layering, unique artistic designs.

Custom Business and Event Signage

Every business needs signage, and every event organizer wants memorable decor. Lasers allow you to create stunning, professional-quality signs from wood, acrylic, or a combination of materials. From rustic cafe menus to elegant wedding welcome signs, laser-cut lettering and logos offer a premium look that stands out.

- Products: Lobby signs, menu boards, direction signs, event decor.

- Value Add: Precise logo reproduction, custom fonts, professional finish.

Niche and Hobbyist Kits

The DIY and hobbyist markets are booming. You can use your laser to create kits for others to assemble, like miniature models, puzzles, or dollhouse furniture. The laser cuts the parts with perfect precision, ensuring they fit together flawlessly. This market offers great potential for online sales and scalability.

- Products: Model airplane kits, 3D puzzles, tabletop game terrain, DIY craft kits.

- Value Add: Perfect part accuracy, easy assembly, access to niche hobbies.

| Application Area | Profit Margin | Scalability | Material Cost |

|---|---|---|---|

| Personalized Home Decor | High | Medium | Low-Medium |

| Business/Event Signage | High-Very High | High | Medium |

| Niche Hobbyist Kits | Medium | Very High | Low |

| Simple Coasters/Tags | Low-Medium | Very High | Very Low |

Why is Fume Extraction the Biggest Wood Laser Cutting Challenge?

You've got your new laser cutter, and you're excited about the designs you can make. You run your first job on a piece of plywood, and it works, but the room quickly fills with a harsh, smoky smell. You figure you'll just open a window, but you quickly realize the problem is much bigger than that. The smoke isn't just annoying—it's a constant, persistent issue.

Ignoring this problem is a critical mistake. This isn't just wood smoke; it's a mixture of fine particulates and chemical fumes from the glues and resins in the wood. It poses a serious health risk to you and your employees, gunks up your laser's sensitive optics reducing performance, and in a commercial setting, can lead to serious compliance violations and fines from workplace safety regulators.

Fume extraction is the biggest challenge because engineered woods like MDF and plywood don't just burn, they release a complex mix of airborne wood dust and chemical vapors, including formaldehyde. In a production environment, this accumulates rapidly, creating a hazardous workspace. A professional operation requires an industrial-grade air filtration system, not just a simple exhaust fan, to safely capture both the solid particles and gaseous compounds, making it a significant but non-negotiable operational cost.

The Health and Safety Risks

This is the most important reason to take extraction seriously. The smoke from laser cutting wood contains two primary dangers.

- Particulates: These are microscopic particles of wood and char that can be inhaled deep into the lungs, leading to respiratory problems.

- Volatile Organic Compounds (VOCs): Engineered woods are made with glues and resins. When the laser vaporizes them, they release chemicals like formaldehyde and benzene, which are known carcinogens and can cause a range of health issues with long-term exposure.

The Impact on Machine Performance

That smoky residue has to go somewhere. A lot of it gets deposited right back onto your machine.

- Dirty Optics: A fine, oily film will quickly coat your laser's focusing lens and mirrors. This coating absorbs laser energy, which reduces your machine's cutting power and can cause your expensive optics to overheat and crack.

- Mechanical Wear: The abrasive dust gets into belts, guide rails, and bearings, accelerating wear and tear and leading to more frequent maintenance and breakdowns.

Choosing the Right System

Not all ventilation is created equal. Understanding the options is key for a purchasing manager like John.

- Exhaust Fan: This is a basic fan that vents fumes to the outside. It's cheap but ineffective for production. It doesn't filter the air, can violate environmental regulations, and doesn't capture the heaviest particles.

- Fume Extractor/Purifier: This is a dedicated, multi-stage filtration system. It pulls the air from the laser, passes it through a series of filters (like a pre-filter for large particles, a HEPA filter for fine particulates, and an activated carbon filter for VOCs), and returns clean air to the room. It is the only safe and compliant solution for a professional environment.

| Ventilation System | Initial Cost | Effectiveness | Best For |

|---|---|---|---|

| Open Window | None | Very Low | Not Recommended |

| Simple Exhaust Fan | Low | Low-Medium | Very light hobby use only |

| Fume Extractor Unit | High | Very High | Commercial & Production Use |

What are Common Problems and Solutions in Wood Cutting?

Your ventilation is handled, but now you're facing new frustrations on the factory floor. Some of your cuts have ugly, dark charring on the edges. Other times, the laser doesn't cut all the way through in certain spots. These inconsistencies are killing your efficiency and wasting material.

Simply repeating a failed job or sanding down every single piece is not a scalable solution. This approach costs you time, money, and ruins your profit margins. The goal of using a laser is automation and perfection. To achieve that, you need to diagnose the root cause of these common issues and implement production-ready solutions, instead of fixing problems one piece at a time.

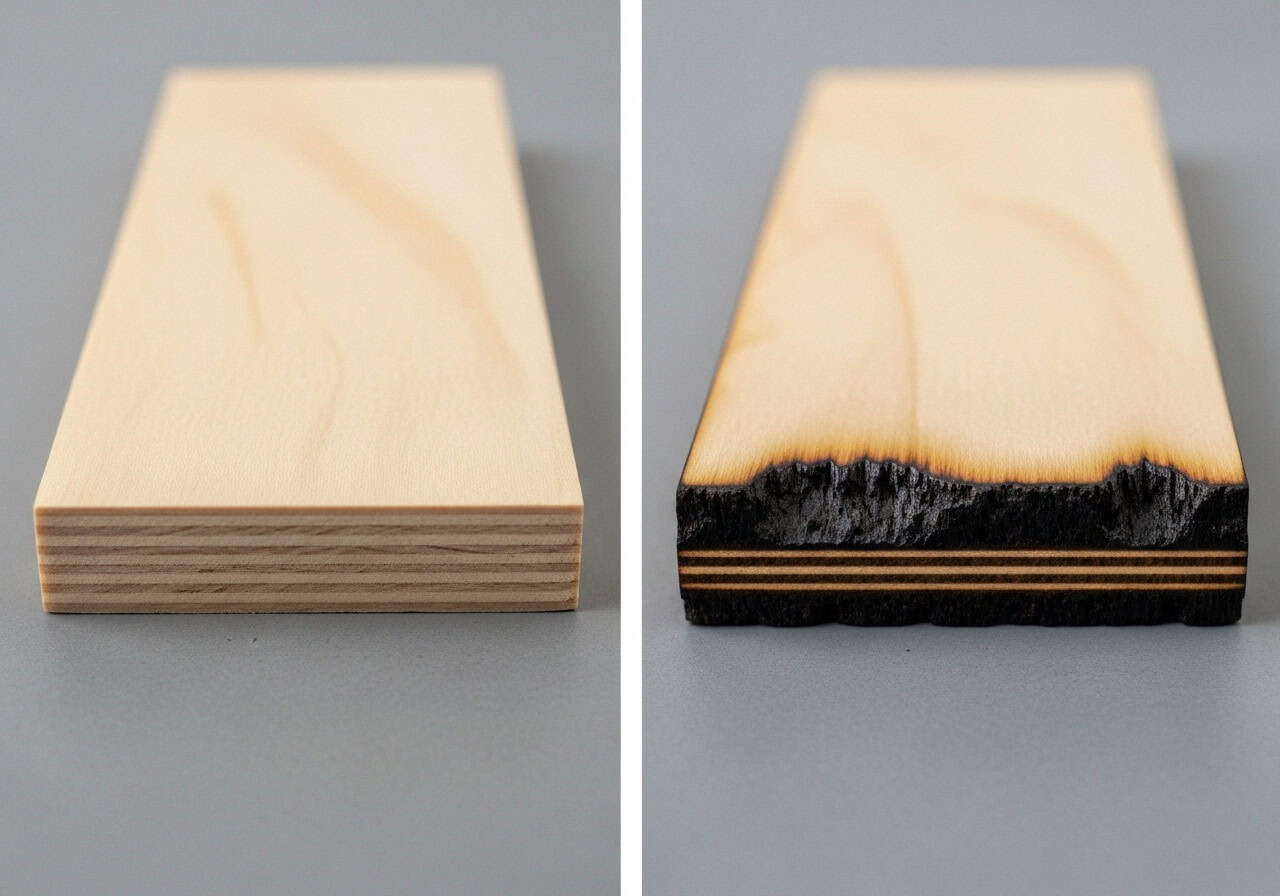

The most common wood laser cutting problems are excessive edge charring, incomplete cuts, and surface flare-ups. Charring is solved by increasing speed and using strong air assist. Incomplete cuts are usually due to warped material or dirty optics that reduce power. Flare-ups are caused by resin pockets in the wood and are minimized by keeping the honeycomb bed clean and using a powerful air assist to blow out the flame.

Problem 1: Excessive Charring

You see a thick, black, sooty line on the edge of your cut instead of a clean, brown edge.

- Cause: The laser is moving too slowly, or the power is too high. The laser energy dwells on the material for too long, essentially burning it instead of vaporizing it. Poor air assist can also contribute significantly.

- Solution: Increase the cutting speed and/or decrease the power. Most importantly, use a strong air assist. The jet of compressed air blows vaporized material out of the cut path before it can ignite and blacken the edge.

Problem 2: Incomplete Cuts

The laser cuts through perfectly in some areas but leaves other sections attached.

- Cause: This is almost always caused by warped material. If a sheet of plywood has a slight wave, the low spots will be further from the nozzle and out of the laser's optimal focal point, receiving less energy. It can also be caused by dirty optics reducing the laser's effective power.

- Solution: First, clean your lens and mirrors. Second, ensure your material is completely flat. Use strong magnets or weights to hold the wood sheet securely against the honeycomb bed. For persistently warped sheets, raising the Z-axis by 1-2mm can sometimes help, but flat material is always better.

Problem 3: Flare-Ups and Stains

As the laser cuts, you see small, sudden flames that leave scorch marks on the surface of your wood.

- Cause: These flare-ups happen when the laser hits a pocket of resin or glue within the plywood or a dense knot in natural wood. The concentrated material ignites. They are also made worse by residue buildup on your honeycomb bed, which can catch fire.

- Solution: Strong air assist1 is your first line of defense, as it blows the flame out instantly. Also, regularly clean your honeycomb bed2 with a degreaser to remove flammable residue. Finally, applying paper masking tape to the wood surface before cutting can protect it from most scorch marks.

Conclusion

The "endless possibilities" of laser-cut wood are real, but they are built on a foundation of operational excellence, not just creative design. As we've seen, the factory floor reality is that managing the downstream effects—the fumes, the residue, the safety compliance—is what separates a hobby from a profitable enterprise. By investing in proper ventilation, understanding how to solve common cut-quality issues, and focusing on high-value products, you can turn the promise of laser cutting into a reliable and scalable business. The machine is just the tool; mastering the entire process is the real key to success.