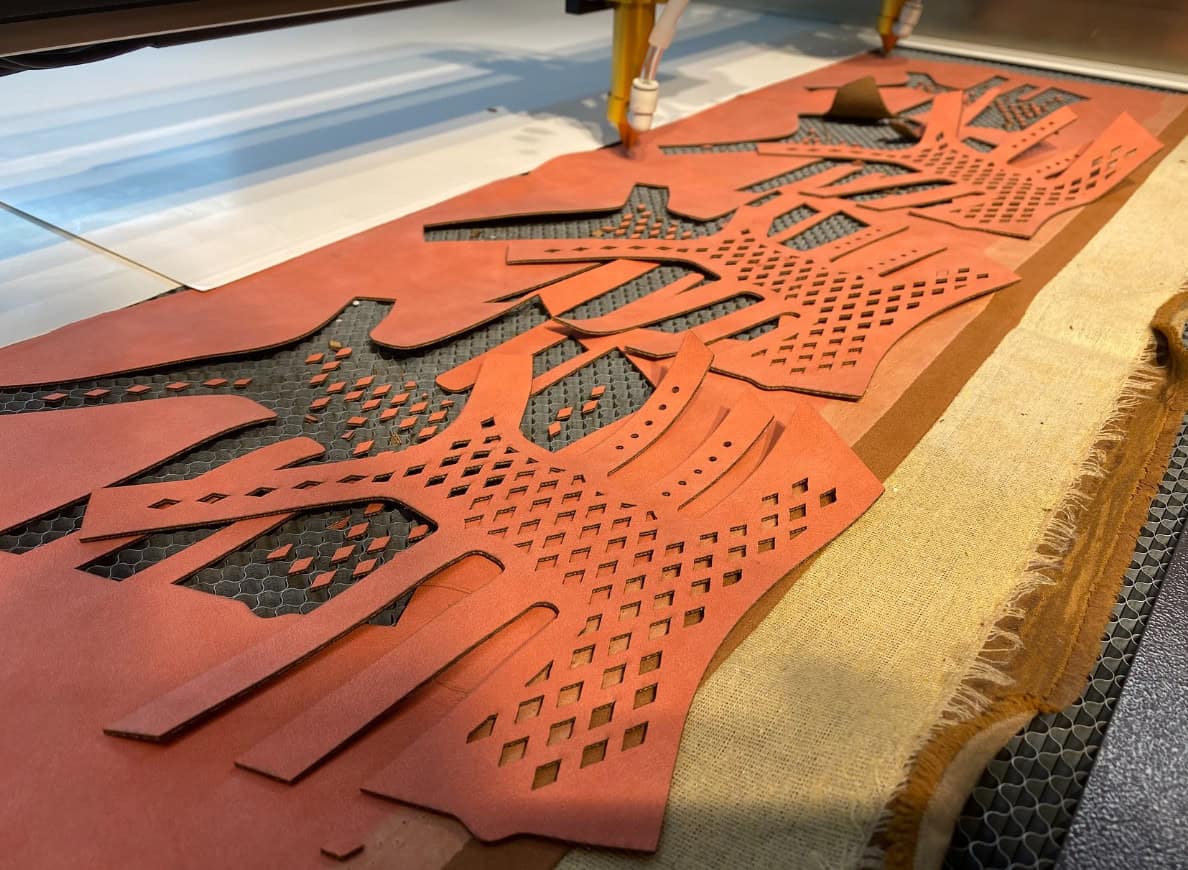

Ergonomic workpiece unloading during cutting

The unloading table acts as an extension, allowing pre – cut textiles to be taken out from the laser system while the cutting process is ongoing. This table extension has an added advantage of permitting material removal from three sides, which further increases flexibility in the production process.

What are the benefits of the additional conveyor belt ?

- Save time by unloading workpieces without disrupting the workflow

- More convenient access to the cut materials

- Optimize the process by promptly adjusting material feed to match the operator's work rhythm

- Optionally, individually adjust the table height for ergonomic unloading

- Adjust the feed cycle according to cutting data with software - controlled optimization

- Nearly seamless cutting for large formats

- Disassembled and assembled , convenient for transportation, saving transportation and machine purchase costs, and saving floor space

Secure material removal without disrupting the manufacturing process.

Post-laser processing, the material is conveyed to the collecting table via a conveyor belt. Owing to the superior-level safety characteristics, the operator is capable of removing the completed components even as the laser operation persists without any halt.

Transport of materials on the safe collection table

Convenient access to individual cut components

The extended table allows operators to easily remove pre-cut parts from the laser system. Especially for wide work surfaces, three-sided access ensures that the ready-to-use materials can be effortlessly reached during the process.

Disassembled and assembled, convenient for transportation, saving transportation and machine purchase costs, and saving floor space.