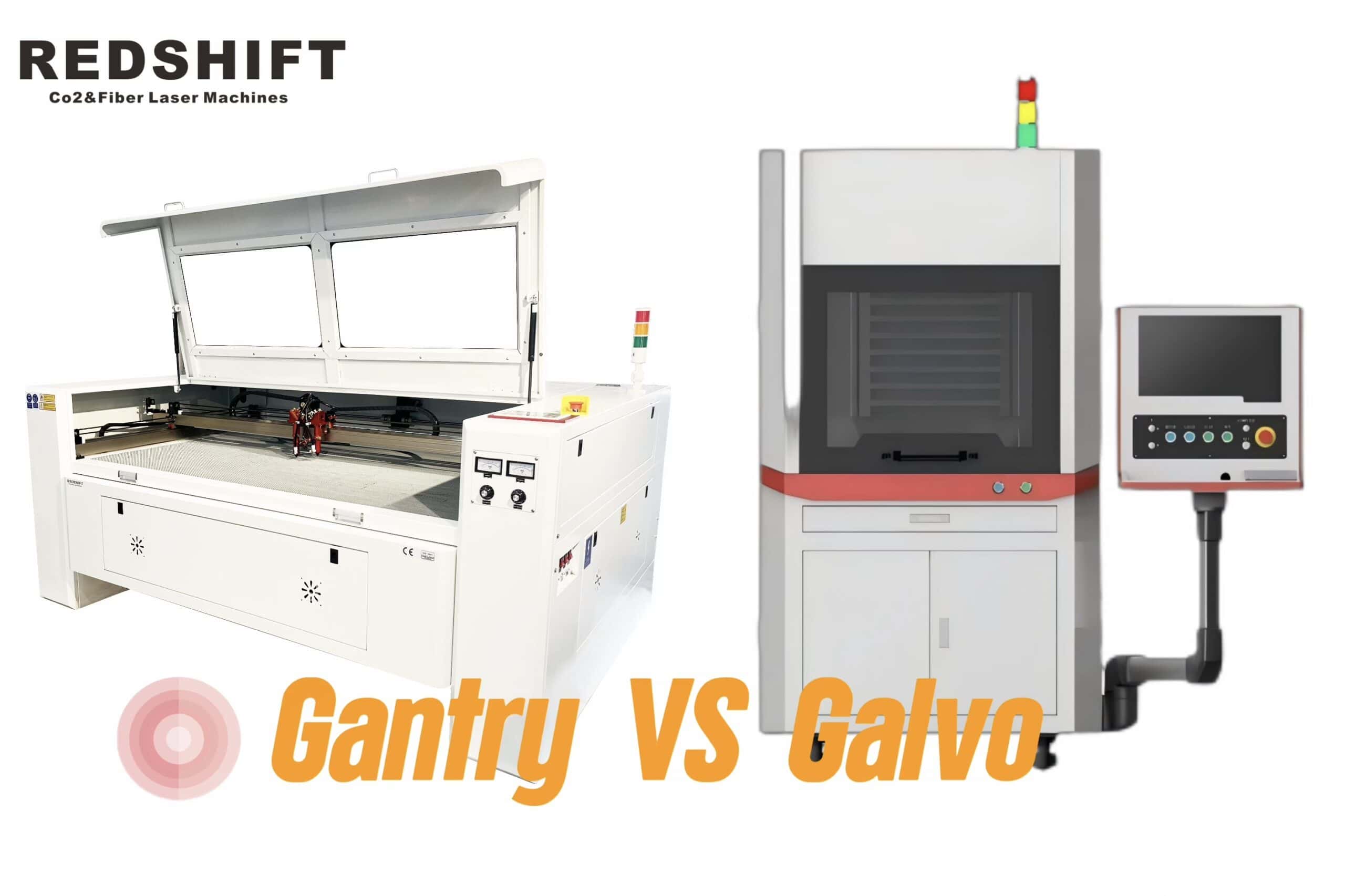

Struggling to choose the right laser for marking? CO₂ laser plotters and galvos differ in speed and precision. Which one suits your business best?

CO₂ laser plotters use gantry systems for consistent engraving depth, while galvos offer high-speed marking with mirrors. Choose based on precision needs and workspace size.

I’ve spent years at Redshift Laser helping clients like John pick the right laser. The choice between plotters and galvos can make or break your production. Let’s dive into the details.

What Are Laser Plotter Machines (Gantry System)?

Tired of inconsistent engravings? Laser plotters use a gantry system to move the laser precisely. They ensure uniform results. Curious how they work?

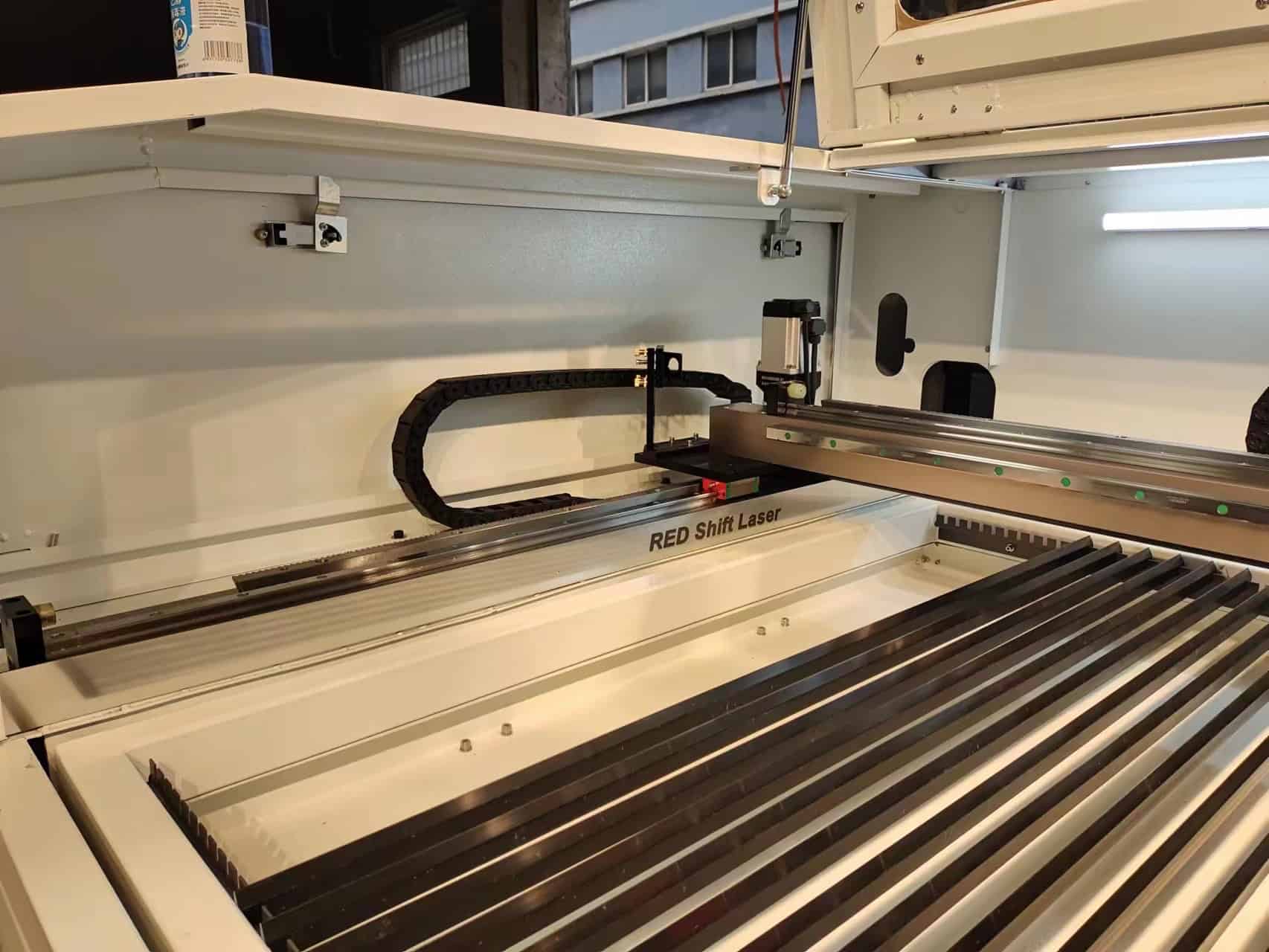

Laser plotters move a laser head on a gantry system, keeping the beam perpendicular. This ensures consistent engraving depth and character shape across large work areas.

Dive Deeper: Understanding Gantry Systems

When I first saw a gantry-based laser plotter at Redshift Laser, I was amazed by its precision. The laser head moves along rails, keeping the beam perfectly perpendicular to the material. This setup shines for large workpieces or detailed engravings. It avoids distortion, which is critical for industries like aerospace, where John sources machines. Uniform depth and character shape are non-negotiable for compliance.

Here’s a breakdown of gantry system benefits:

| Feature | Benefit |

|---|---|

| Perpendicular Beam | Consistent engraving depth |

| Large Workspace | Handles bigger materials |

| Stable Motion | Reduces errors in detailed designs |

Gantry systems excel when precision matters most. They’re slower than galvos but deliver unmatched consistency. For John, this meant reliable marking for medical devices, ensuring every part met strict standards. If your work demands flawless results, a gantry system could be your best bet.

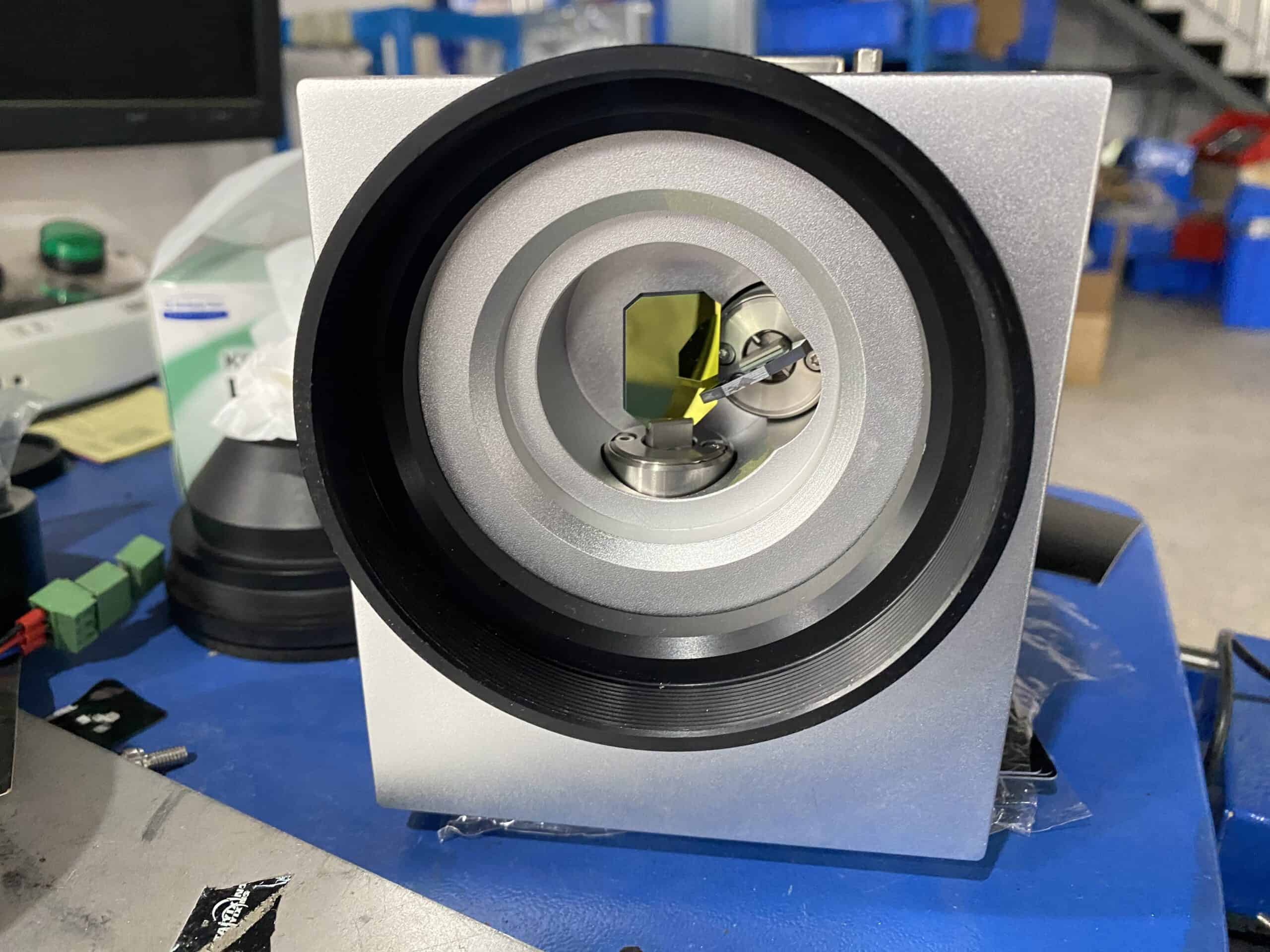

What Is a Galvo Laser and How Does It Work?

Need speed in your marking process? Galvo lasers use mirrors to direct the beam quickly. They’re fast but have limitations. Want to know more?

Galvo lasers use rotating mirrors to direct the beam, enabling high-speed marking. They’re ideal for small areas but may show slight distortion at the edges.

Dive Deeper: How Galvo Lasers Operate

I once helped a client switch to a galvo laser for faster production. The speed was incredible—mirrors move the beam in milliseconds. At Redshift Laser, we’ve seen galvos transform workflows for clients like John, who needed quick turnaround for packaging. However, the mirrors angle the beam, causing slight focal distortion at the edges. This can elongate characters, which isn’t ideal for precise applications.

Here’s how galvo lasers perform:

| Feature | Benefit |

|---|---|

| High-Speed Marking | Completes jobs quickly |

| Compact Design | Fits smaller workspaces |

| Mirror-Based Control | Enables rapid beam movement |

For most consumer goods, this distortion is negligible. But for John’s aerospace clients, it’s a dealbreaker due to UDI compliance. Galvos are perfect for high-volume, less critical tasks. If speed is your priority, a galvo laser could be the answer.

Gantry vs. Galvo: How Do They Compare for Marking & Engraving?

Confused about which laser system to choose? Gantry and galvo lasers differ in speed, precision, and workspace. Which one fits your needs best?

Gantry lasers offer precision and large workspaces, ideal for detailed engravings. Galvo lasers prioritize speed, suiting high-volume tasks but may distort at edges.

Dive Deeper: Comparing Gantry and Galvo

I’ve seen clients wrestle with this choice at Redshift Laser. Gantry systems move slower but maintain a perpendicular beam, ensuring consistent engraving depth. Galvos, with their mirror-driven beams, are faster but introduce slight distortion at the edges. For John, this was critical. His medical device clients needed perfect traceability, so gantry systems won. But for packaging, galvos were faster and sufficient.

Here’s a comparison:

| Aspect | Gantry | Galvo |

|---|---|---|

| Speed | Slower, steady motion | High-speed mirror movement |

| Precision | Consistent depth, no distortion | Minor distortion at edges |

| Workspace | Large, versatile | Smaller, focused area |

Gantry systems suit large or precise projects. Galvos excel in high-speed, smaller-scale tasks. Your choice depends on your industry’s demands. For John, balancing speed and compliance was key. Understanding these trade-offs helps you pick the right tool.

How Do You Choose the Right CO₂ Laser Marking Machine?

Overwhelmed by laser options? Choosing the right CO₂ laser depends on your workload and precision needs. Ready to make the right decision?

Choose a CO₂ laser based on workload, material, and precision needs. Gantry systems suit large, precise tasks; galvos excel for fast, small-scale marking.

Dive Deeper: Making the Right Choice

At Redshift Laser, I’ve guided clients like John through this decision. Gantry systems are best for large workpieces or when precision is critical, like in aerospace or medical devices. Their perpendicular beam ensures consistent quality. Galvos, however, shine for high-speed tasks on smaller areas, like packaging. The physics matters—gantry avoids distortion, while galvo’s mirrors may cause slight elongation.

Here’s a decision guide:

| Factor | Gantry Preference | Galvo Preference |

|---|---|---|

| Workpiece Size | Large materials | Small to medium materials |

| Precision Needs | High (e.g., medical, aerospace)1 | Moderate (e.g., consumer goods) |

| Production Speed | Slower, steady | High-speed, high-volume2 |

Consider your industry. John chose gantry systems for compliance-driven projects but used galvos for faster consumer goods tasks. Think about material type, production volume, and quality standards. A clear understanding of your needs ensures you pick the right machine.

Conclusion

CO₂ laser plotters ensure precision for large, critical tasks. Galvos offer speed for smaller jobs. Choose based on your needs to boost efficiency and quality.