Below is a comparative analysis of Gantry and Galvo CO₂ laser systems for automotive interior processing, focusing on efficiency, key characteristics, and alignment with automotive material requirements (e.g., leather, fabrics, soft PVC/PU materials, plastic trim panels) and practical needs.

Content

Hide

1. Core Principle Differences

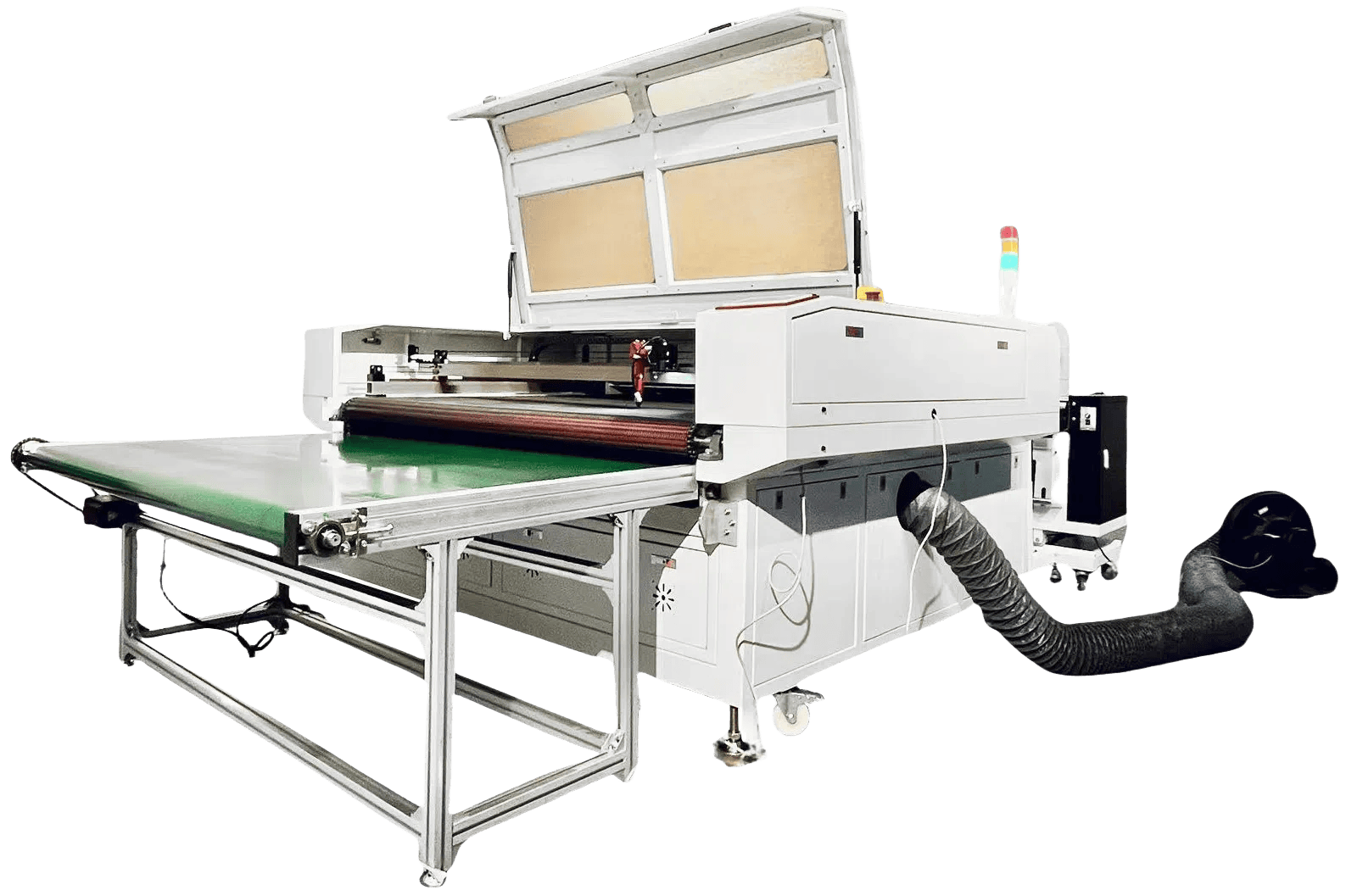

- Gantry Systems: These use linear/servo motors to drive the laser head along X-Y axes via a gantry structure, covering large processing areas. The laser beam remains fixed while the gantry moves, making them ideal for large, complex, or continuous machining tasks.

CO2 Laser Cutter with Conveyor and Collection Table

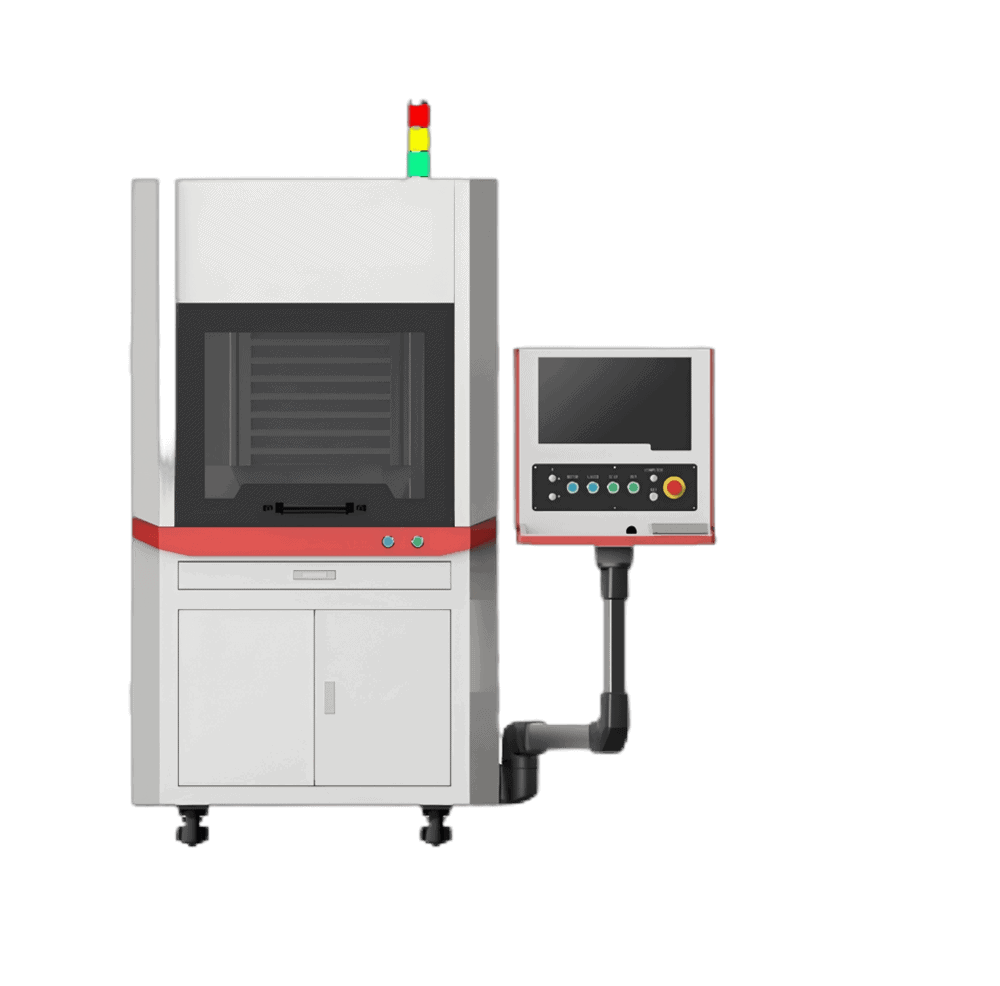

- Galvo Systems: These rely on high-speed galvanometer mirrors to deflect the laser beam (with frequencies up to thousands of Hz). The laser head stays fixed, and the beam scans across the target area, excelling at small, high-speed, localized processing.

CO2 Galvo Laser Engraving Machine

2. Efficiency Comparison (Automotive Interior Context)

| Dimension | Gantry Systems | Galvo Systems |

| Large-Area Processing | High efficiency. Ideal for one-piece or large-area jobs with minimal idle time.<br>Example: Full-scale cutting of automotive seat leather (1.5m×1m) – no need for repeated repositioning, reducing idle movement. | Lower efficiency. Limited by scan range (typically 0.1-0.5m²). Large areas require stitching/scanning in zones, with efficiency dropping as size increases. |

| Small-Area/Precision Work | Moderate efficiency. Mechanical movement involves acceleration/deceleration, wasting time on small zones.<br>Example: Engraving trim strips on seat sides (5cm×10cm) – requires positioning before processing, taking longer than Galvo. | Extremely high efficiency. Scanning speeds reach 5-10m/s, completing small tasks in milliseconds.<br>Example: Marking a dashboard logo (2cm×2cm) – done in <0.1 seconds. |

| Multi-Process Integration | High efficiency. Supports integrated cutting, engraving, and marking in a single setup.<br>Example: One-piece processing of automotive door panel upholstery – "cut contour + engrave ventilation holes + mark model number" in one cycle. | Lower efficiency. Requires re-calibration when switching processes, and multi-step tasks need repeated positioning.<br>Example: Switching from marking to cutting on the same workstation demands pausing to adjust parameters. |

3. Key Characteristics (Alignment with Automotive Interior Needs)

| Dimension | Gantry Systems | Galvo Systems |

| Precision & Stability | High precision. Rigid gantry structure ensures repeatability accuracy of ±0.02-0.05mm.<br>Ideal for automotive interiors requiring clean edges (e.g., burr-free leather cutting). | Moderate precision. Susceptible to temperature/vibration, with long-term accuracy of ±0.05-0.1mm.<br>Suitable for less critical tasks (e.g., marking soft materials). |

| Material Adaptability | Broad. Handles thick/hard materials.<br>Example: Cutting rigid PVC dashboard panels (3-5mm thick) with high-power CO₂ lasers (100-200W). | Narrower. Best for thin/soft materials.<br>Example: Efficient cutting of seat PU leather (0.8-1.5mm) or fabrics – fast scanning reduces heat buildup, preventing scorching. |

| Cost & Maintenance | Higher cost. Complex gantry structures (motors, rails) require specialized maintenance.<br>Suitable for high-volume production (e.g., annual output of 100k+ vehicle seats). | Lower cost. Simple design with no long-moving parts reduces maintenance.<br>Ideal for small-batch, high-variety production (e.g., custom interior modifications). |

| Flexibility | Lower flexibility. Paths require pre-programming; switching workpieces demands re-debugging.<br>Example: Changing seat sizes requires re-setting gantry trajectories. | High flexibility. Only path files need adjustment – no mechanical reconfiguration.<br>Example: Quickly switch between marking logos for different car models (e.g., entry-level vs. luxury trims). |

| Heat-Affected Zone (HAZ) Control | Moderate. Prolonged laser exposure during long-stroke processing causes localized heat buildup.<br>Example: Cutting dark fabrics may lead to slight edge shrinkage. | Excellent. Fast scanning and short dwell times minimize HAZ.<br>Example: Cutting light-colored leather preserves edge color, eliminating post-processing. |

4. Typical Automotive Interior Applications

Gantry Systems:

- Large, high-precision tasks: Full-scale cutting of seat leather (matching seat contours), contour cutting of door panel upholstery (e.g., curved edges), layered cutting of composite materials (leather + foam + plastic in dashboards).

- Multi-process workflows: Integrated cutting, engraving (ventilation holes), and marking (model codes) in a single workstation.

Galvo Systems:

- Small, high-frequency tasks: Quick marking of seat trim labels (material tags), fine engraving of steering wheel logos (detailed patterns), or simulating heat-transfer patterns on headliners (replacing traditional methods).

- Flexible production: Rapid reconfiguration for custom interiors (e.g., replacing embroidered logos with laser-marked alternatives in premium vehicles).

Summary

Gantry and Galvo systems serve distinct needs in automotive interior processing – neither is universally "better."

- Choose Gantry for large, high-precision, or multi-step tasks (e.g., mass-producing seat/door panel upholstery).

- Choose Galvo for small, frequent, or flexible jobs (e.g., marking, engraving small components) or thin/soft materials (leather/fabrics).

In practice, combining both (e.g., Galvo for marking + Gantry for cutting) creates a cost-effective, efficient production line.